Once recovered, wood waste can be combined with plastics to form wood-plastic composites, which have a wide scope of potential uses. A paper published in Polymers has explored this subject.

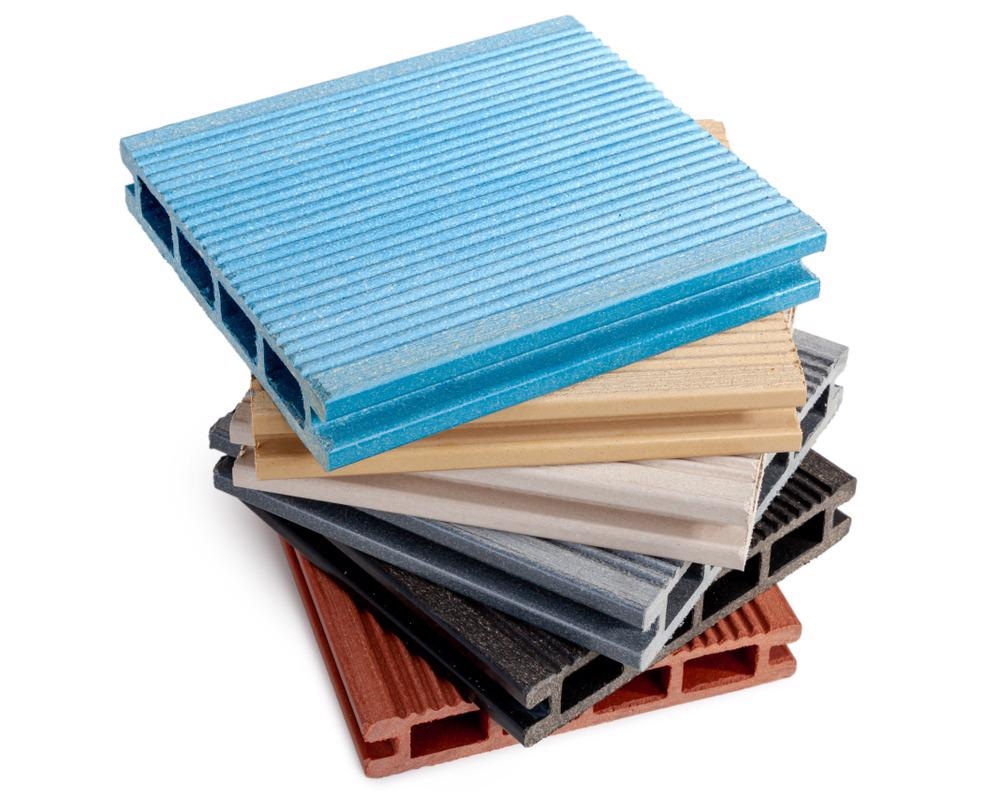

Study: A Critical Review on Wood-Based Polymer Composites: Processing, Properties, and Prospects. Image Credit: Krashenitsa Dmitrii/Shutterstock.com

One of the central elements of the circular economy concept is the value-added utilization of waste streams by industry. For example, recovering and recycling wood waste from construction and demolished structures is envisioned as a key part of achieving circularity in the construction industry.

The Study

The new study published in Polymers has presented a critical review of wood-polymer composites and current literature. The review focuses on the processing of these materials along with additives, including wood flour and various mechanical, morphological, and structural properties of these important materials.

The review also highlights the various commercial applications of wood-polymer composites, including architecture, marine, automotive, and defense applications. By presenting this critical review, the authors have provided a knowledge base for future applications and research perspectives on wood-polymer composites.

Wood-Polymer Composites

Wood is a natural, sustainable material that is utilized by numerous industries for its mechanical, physical, and chemical properties. The hierarchical structure of wood influences its structural performance. However, in its natural form it has limited commercial utility.

Wood, in microfiber and powder form, can be combined with other materials to make composites with enhanced mechanical and physical performance. Amongst these composite materials, wood-polymer composites have been studied extensively in recent years. Polymers typically added to these composites include rayon, polyamide, and latex.

Advantages of wood-polymer composites include resistance to harmful organisms such as insects and fungi, cost-effective and efficient production methods, sustainability, high relative stiffness, and high dimensional stability over the course of their lifetime. They have proven especially useful for replacing natural wood in applications that are exposed to elevated levels of moisture, such as planks and cladding, due to superior waterproofing elements in the composite material.

Additionally, they have found application in soundproofing and the automotive industry, as well as additives for fuel, replacing non-renewable coal resources. The sustainability of wood-polymer composites can be enhanced even further if the polymer is derived from a recycled source.

Disadvantages of Wood-Polymer Composites

On the other hand, there are some disadvantages to these composite materials. Firstly, the selection of available matrixes is limited. Additionally, natural fibers can be combustible at elevated temperatures and can degrade naturally over time (inorganic additives such as aluminum and magnesium sulfate have been studied to improve the resistance of composites.) It is also broadly acknowledged that only plastics which have a low melting point can be used as composite materials.

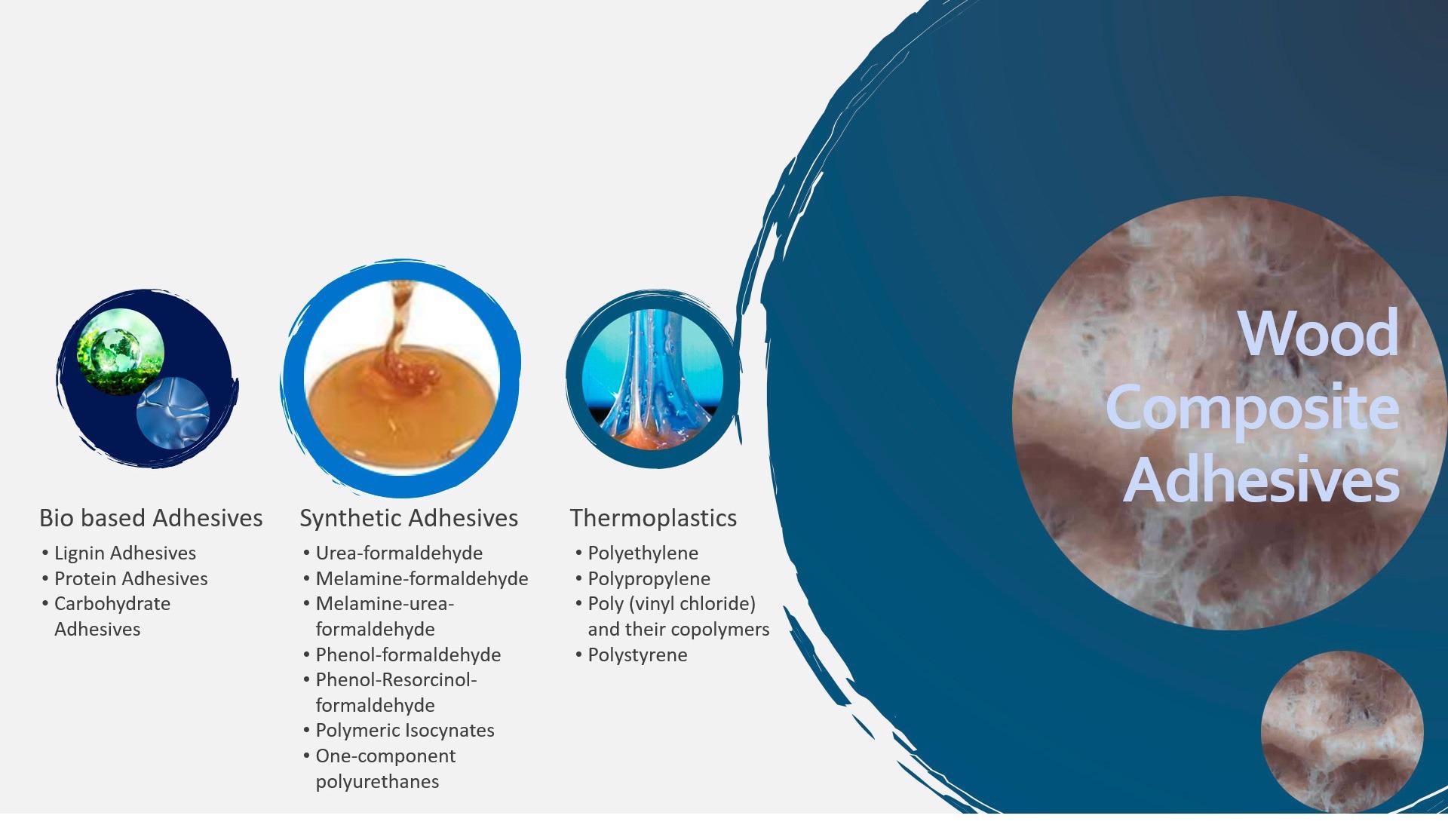

Adhesives for wood composites. Image Credit: Ramesh, M et al., Polymers

Viable polymers are limited, mainly including polyethylene, polyvinyl chloride, Styrofoam, polycaprolactone, and a few others. Other polymers have been explored in recent studies, such as thermoplastic polyurethane and polylactic acid. Bio-based adhesives such as lignin and tannin can also be used as additives in composites. Current studies have discussed the complete replacement of synthetic polymers with organic alternatives.

Additionally, wood-polymer composites can be brittle and display unsatisfactory strength and stiffness unless coupling agents and toughening agents are introduced into their matrices. Their efficacy can be greatly improved by the introduction of bonding chemicals. Some authors in the current literature have reported a 40% increase in stiffness, a doubling of impact resistance, increased density, and a two to fourfold increase in tensile and flexural strength by using correctly recruited pairing entities.

Wood-Polymer Composite Processing

Wood-polymer composites can be manufactured using several commonly available thermoplastic processing techniques such as extrusion and injection molding. However, these processes have limited scope, so research is ongoing into alternative processing methods. In order to improve the processing of wood-polymer composites, rheological categorization techniques are commonly employed in research to evaluate the influence of formulation and processing parameters on the properties of finished products.

A challenge in wood-polymer composite processing is achieving the optimal wood/polymer mix. Ineffective or excessive mixing can cause damage to the wood and polymer fibers, and the extent of blending is a critical parameter for achieving the optimal mechanical performance of finished products.

In Summary

Summing up, the new study published online in Polymers presents a comprehensive critical review of current research perspectives, commercial uses, processing methodologies, and material characterizations of wood-polymer composites. The authors have provided a significant knowledge base for future research into the manufacture of commercially viable composite materials with enhanced properties.

Wood-polymer composite materials offer significant potential for improving the sustainability and eco-friendliness of sectors such as the construction and automotive industries. The possibility of using waste materials improves the circularity of multiple industries and reduces the need for virgin resource utilization. Future research directions in this area should prove interesting.

Further Reading

Ramesh, M et al. (2022) A Critical Review on Wood-Based Polymer Composites: Processing, Properties, and Prospects [online] Polymers 14(3) 589 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/3/589

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.