A new study published in the journal Energies has reviewed the strategies used to estimate power loss in turbines caused by exposure to adverse weather conditions.

Study: A Review on the Estimation of Power Loss Due to Icing in Wind Turbines. Image Credit: TebNad/Shutterstock.com

Wind turbines are a vital renewable energy technology that is helping the world to progress beyond relying on fossil fuels for its power needs. However, the performance of wind turbines is affected by adverse weather conditions.

Harnessing Wind Power in Colder Climates

Colder climates including the Nordic countries have a high potential for wind power generation, with an abundance of this natural, renewable resource during the winter months when the wind is stronger, and the air density is higher. This is due to a varying relationship between available wind power and wind speed.

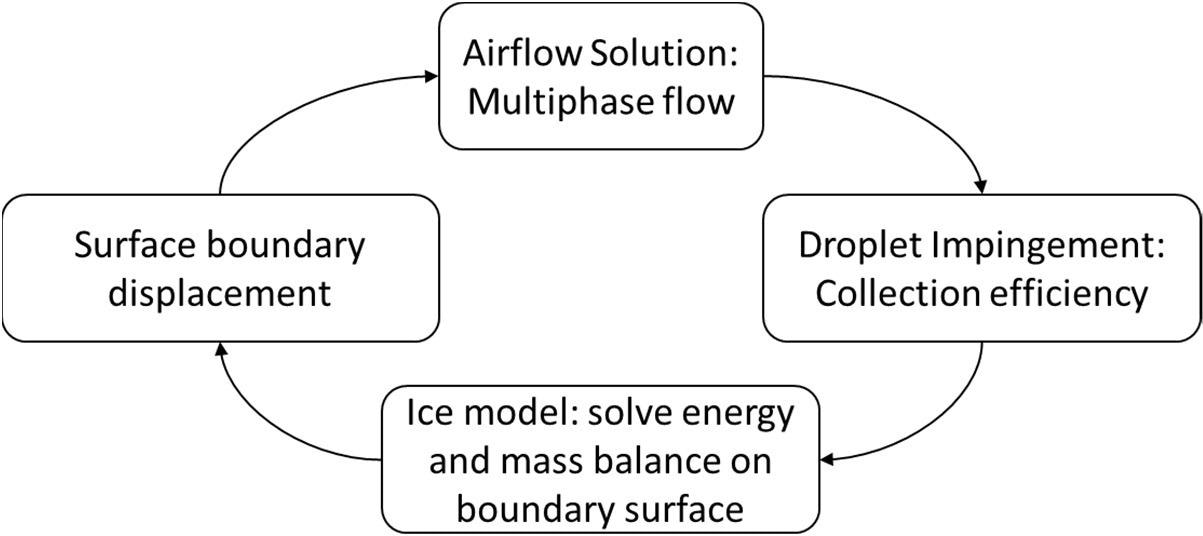

Diagram of ice accretion model based on CFD. Image Credit: Contreras M et al., Energies

The International Wind Technology Collaboration Task 19 estimates that in 2020 the wind generation capacity of colder climates reached 156 GW, and by 2025 this figure is estimated to reach 224 GW. However, there are issues with turbine blade performance in low temperatures.

Ice causes changes in the aerodynamic properties of wind turbine blades, such as their lift and drag coefficients. Consequently, the performance and power output of turbines can drop, or ice can stop the turbines from working altogether. Furthermore, the weight of ice on the turbine blades can cause an increase in load, leading to induced fatigue of components and safety issues caused by ice being expelled from moving blades.

Annual performance losses from the effects of icing have been estimated at 20% of annual power output and between 20% and 50% for aerodynamic performance. Understanding predicted performance loss during colder months and icing events helps to maximize a turbine’s energy production in these weather conditions.

Understanding the Icing Phenomenon

The icing phenomenon is complex, depending on multiple factors such as wind speed, the blade’s angle of attack, blade geometry, water droplet size, air temperature, pressure, humidity, the point of operation, and so forth. This, along with a lack of simulations that reliably predict icing events, has limited the understanding of the phenomenon. Many models, for example, predict rime ice formation on turbine blades, with very few accurately predicting glaze ice formation.

Additionally, multiple models of ice accretion have concentrated on two dimensions, for example, the blade’s airfoil section. However, the geometry of many wind turbine blades in use today is complex and twisted, typically composed of numerous section forms. Three-dimensional simulations are more appropriate for this kind of geometry. Moreover, simulations are cheaper than trial-and-error efforts and can be endlessly performed and reproduced.

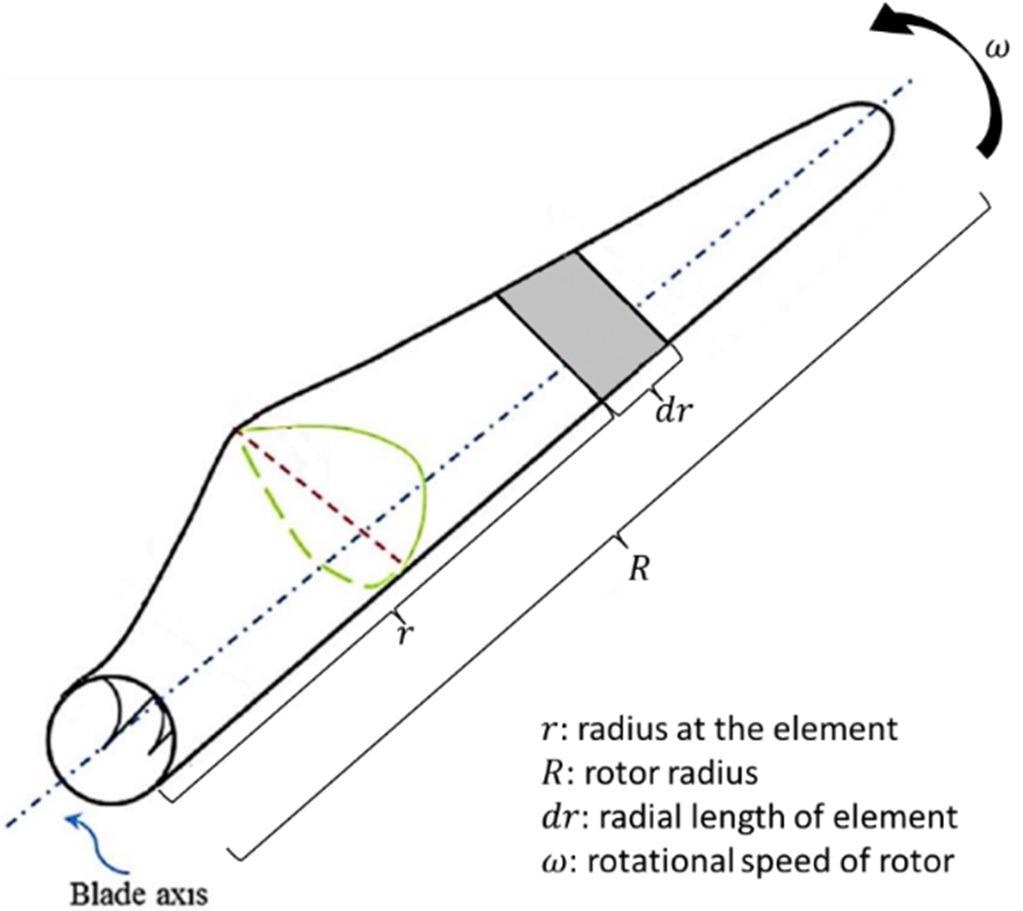

Diagram of blade elements. Image Credit: Contreras M et al., Energies

Additionally, icing does not only affect the blade: it also affects the many components of a wind turbine with various 3D effects. These include the effect of airflow along with the radial direction caused by the rotation of the blades. Complex fluid-structure interactions and complicated flow patterns occur.

3D numerical modeling of ice accretion on wind turbine blades is a complex process. Parameters such as water droplet size and behavior, airflow simulation, ice shape prediction, the thermodynamics of iced surfaces, and boundary layer characteristics need to be included in simulations. Amongst current techniques, some notable examples are TURBICE, LEWICE, FENSAP-ICE, and Makkonen’s Empirical tuned cylinder-based model.

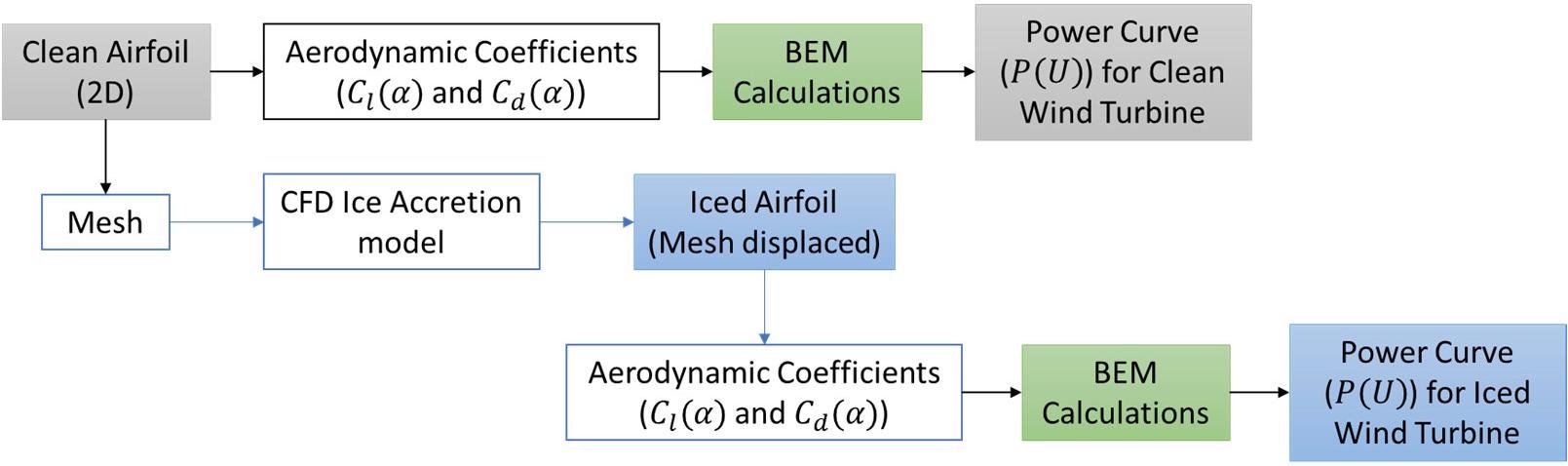

The Paper

The paper published in Energies focuses on state-of-the-art numerical models such as Computational Fluid Dynamics (CFD) for wind turbine power loss estimations under icing conditions. Additionally, a numerical model known as the Blade Element Momentum (BEM) is demonstrated for the aerodynamic analysis of turbines. Knowledge guidelines for modeling the icing phenomenon are provided in the study, and the paper examines available numerical techniques for quantifying turbine power loss under icing conditions.

Diagram of CFD–BEM method. Image Credit: Contreras M et al., Energies

Methodologies used over the last 15 years to estimate power loss in adverse meteorological conditions are reviewed in the study. Additionally, a brief review of other methods such as deep learning, image analysis, and forecasting models is presented in the research. The authors have stated that the paper contributes to improving power-loss prediction and can be used to improve icing protection systems.

The research found that power loss is observed as soon as icing conditions occur, with annual production losses dependent on factors such as duration, intensity, and frequency of icing events. Both full CFD and CFD-BEM methodologies estimated power losses between 8% and 30%. Discrepancies were observed which the authors stated could be to do with assumptions made in the CFD-BEM methodology, highlighting the importance of considering complex 3D airflow around the iced airfoil.

The authors identified issues with full CFD methodologies, in particular the high computational cost. Another issue is the lack of real-world data on icing events that makes the accuracy of models difficult to validate. Additionally, the type of accreted ice is a factor that influences the simulation process. Moreover, most simulations were conducted in a stationary or quasi-stationary state which does not mirror real-world conditions. These are just a few examples of the issues identified in the study.

Despite the challenges identified, there has been progress made in the application of CFD simulations to model power and performance loss during icing events. The authors have stated that further work will need to be performed on simulating entire turbines, using transient methodologies to predict ice growth and overall performance issues. This would enhance understanding of the effect on the entire turbine.

Further Reading

Contreras Montoya, L.T, Lain, S & Ilinica, A (2022) A Review on the Estimation of Power Loss Due to Icing in Wind Turbines [online] Energies 15(3) 1083 | mdpi.com. Available at: https://www.mdpi.com/1996-1073/15/3/1083

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.