Reviewed by Alex SmithFeb 8 2022

The developers of a unique type of lightweight 3D-printed back brace that can sense how well it fits patients claims it could result in better scoliosis therapy.

Image Credit: University of Glasgow.

Scoliosis, a frequent type of spine deformity, affects about 3% of the population, with the majority of cases occurring between the ages of 10 and 15. In younger people, it can be rectified with a back brace that is worn until the growth is halted in the children.

While back brace treatment is beneficial, it can be painful and finding the ideal fit for each patient can be a time-consuming trial-and-error procedure.

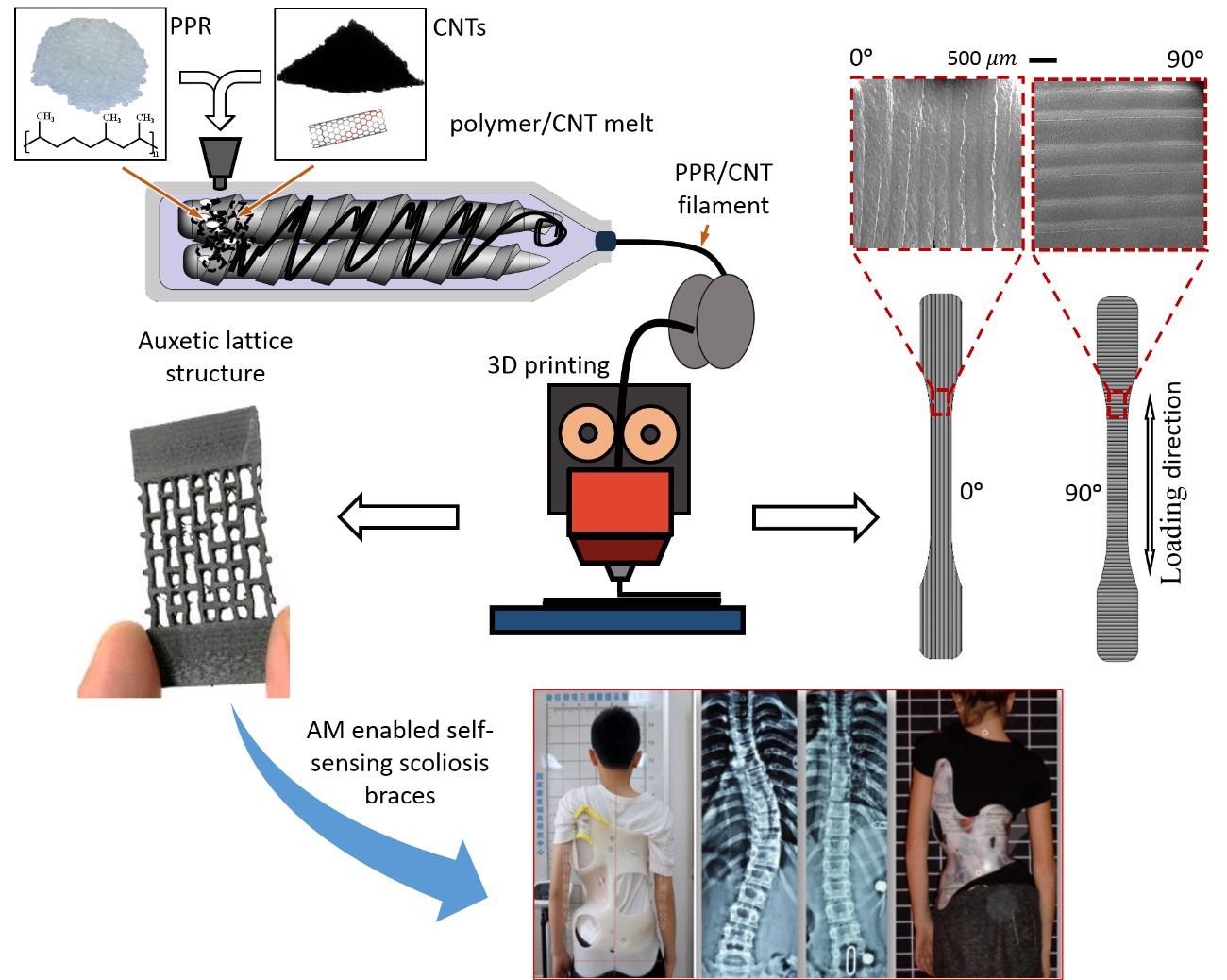

Polypropylene, a lightweight recyclable plastic, was coupled with carbon nanotubes by a team of engineers and physicians from the United Kingdom and the United States to produce a cellular material capable of measuring the amount of strain (and stress) it endures while in use.

According to the researchers, this material might be utilized to construct a “smart” brace that can detect the stress it applies to the human body, resulting in better fine-tuning as well as a more relaxing treatment process.

The University of Glasgow-led researchers explain how carbon nanotubes embedded in a polypropylene random copolymer provided the ability to establish an electrically conductive network across its structure. The research was published in the journal ACS Applied Materials and Interfaces.

They created lattice-like structures out of the material using 3D printing and subjected them to static and cyclic loadings while monitoring how the electrical resistance of the smart composite changed under strain.

This measurement of the material’s changing piezoresistance could one day aid in the development of a smart brace by enabling doctors to identify which parts of the body are generating the most pressure on the brace.

Their experiments revealed that the material preserved its capacity to perceive strain even after 100 cycles of loading and unloading, implying that it could be clever enough to be used in a brace.

The paper’s corresponding author is Dr Shanmugam Kumar of the James Watt School of Engineering at the University of Glasgow.

The research was also supported by colleagues from Texas A&M University, Massachusetts General Hospital, and Massachusetts Institute of Technology in the United States of America.

Scoliosis is a painful and debilitating disorder, and while the current generation of braces is better than they have ever been, there is still a lot of room for improvement.

Dr. Shanmugam Kumar, James Watt School of Engineering, University of Glasgow

“The self-sensing material that we’ve developed has a great deal of potential to deliver that next generation of improvement. What we hope to see is a future where scoliosis patients can be individually assessed by a doctor and have a 3D-printed brace produced for them which is unique to their condition,” he added.

Then, after a few weeks of wearing it, they can return to their doctor and use the readout from the piezoresistive strain sensing brace to have it adjusted to make it even more effective, without the trial-and-error process that clinicians have to rely on at the moment.

Dr. Shanmugam Kumar, James Watt School of Engineering, University of Glasgow

Dr. Kumar also explained, “That could help patients benefit from more accurate adjustments to the stiffness of the bracing in different directions, better data to inform the optimal timing and manner of brace adjustments. That would make them a potentially significant improvement over conventional rigid bracing made from passive materials via conventional manufacturing approaches.”

“Cellular designs of smart composites make the braces lightweight besides offering tunable mechanical and functional attributes,” he said.

We’re keen to explore the real-world applications for this technology, and we’re in the early stages of talks with doctors here in the UK and a medical devices company to look at the possibility of trialing these braces in a clinical environment.

Dr. Shanmugam Kumar, James Watt School of Engineering, University of Glasgow

Journal Reference:

Verma, P., Ubaid, J., Varadarajan, K. M., Wardle, B. L., Kumar, S. (2022) Synthesis and Characterization of Carbon Nanotube-Doped Thermoplastic Nanocomposites for the Additive Manufacturing of Self-Sensing Piezoresistive Materials. ACS Applied Materials & Interfaces. doi.org/10.1021/acsami.1c20491.