The 21st century has been defined by several emerging technologies. Amongst these, additive manufacturing has been widely explored in numerous industries for the printing of 3D structures with complex morphologies and enhanced properties. A paper currently in pre-proof in the journal Additive Manufacturing has investigated the use of digital light process for 3D printing multiceramic materials and device components.

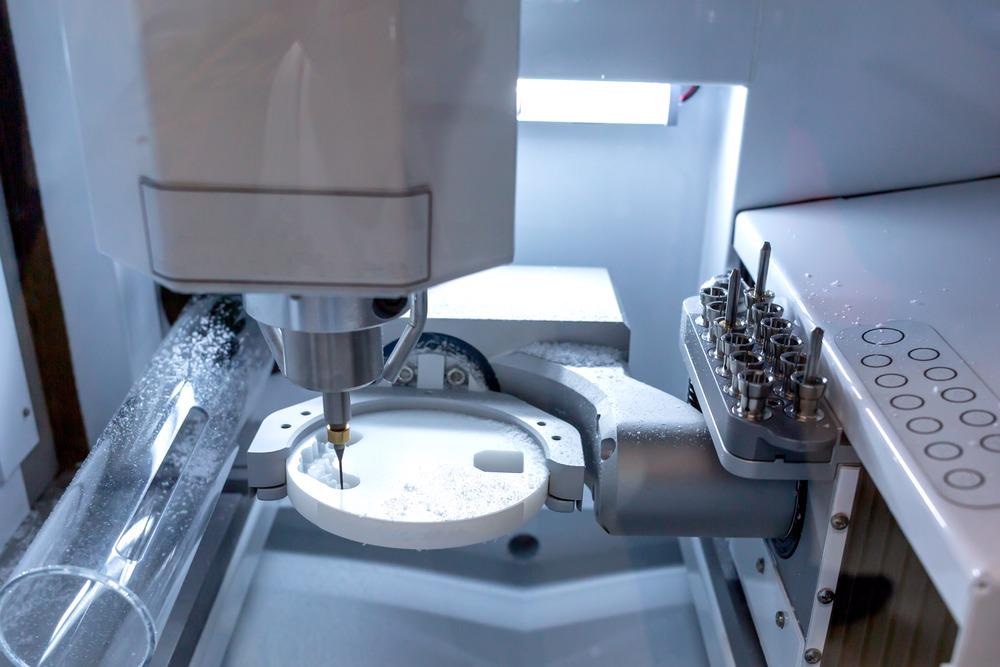

Study: High-resolution multiceramic additive manufacturing based on digital light processing. Image Credit: ANDRIY B/Shutterstock.com

Conventional Ceramic Material and Component Forming

Ceramic materials have found numerous applications in fields such as biomedical engineering, electronics, and aerospace due to their superior properties such as thermal and chemical stability, high strength, and hardness. Several different classes of ceramic materials have been fabricated using traditional forming techniques, such as laminated ceramics, porous ceramics, toughening ceramics, and multiphase ceramics.

However, traditional forming techniques cannot meet the demands of high-performance ceramic materials. For example, the toughness of laminated ceramics can be improved by combining high-temperature sintering and tape casting methods, but the flexibility of material integration and production efficiency is generally not sufficient.

The drawbacks of conventional forming processes have facilitated the need for advanced ceramic-forming technologies with improved production efficiency, which produce components with complex architectures and good surface quality. Additionally, the integration of multiple ceramic materials can be facilitated using advanced methods.

3D Printing Multiceramic Materials and Components

3D Printing has been widely explored in recent years to produce components from multiple materials which possess superior properties and complex architectures to produce high-precision parts. Various techniques have been used for printing materials such as ceramics, resin, and metals. These include direct ink writing, inkjet printing, stereolithography, fused deposition modeling, two-photon polymerization, selective laser melting, and direct light processing (DLP.)

However, most of these 3D printing techniques are designed for printing single materials, which limits their application for producing multimaterial parts. Therefore, the need for new techniques which can handle multiple materials and print components which take advantage of them is needed. Extrusion-based methods such as direct ink writing and inkjet printing use a nozzle to extrude a ceramic slurry and can be easily transformed from printing single materials to multiple materials.

However, extrusion-based 3D printing techniques suffer from limitations in terms of low precision and density of printed parts. Due to these drawbacks, there has been an increasing research focus on direct light printing. This technique is a type of mask-based stereolithography, where the design is transferred to a photocurable liquid surface via exposure of an ultraviolet light source through a patterned mask.

Photocurable slurries of resin or ceramic/metal mixtures are used as the raw materials to fabricate complex components layer-by-layer. The advantages of this technique are high precision and efficiency, and to date, there have been several studies on using low-viscosity resins. Other studies have investigated the manufacture of designs with flexible material and structure performance by integrating different materials in the same layer.

Compared to 3D printing of multimaterial photocurable resins, printing multiceramic materials which contain resin and abundant ceramic particles using this process has proven challenging. The high viscosity of ceramic slurries presents problems for the coating and cleaning processes required for multimaterial printing. Moreover, the complex refractive indices of the ceramic slurry’s different phases can cause UV light scattering, leading to further problems. It can be difficult to control the precision of interfaces between different materials in printed slurries.

Recent research has reported fabricating gradated components with multiceramic materials by depositing different ceramics layer-by-layer. Studies have not addressed interface quality and printing precision.

The Study

In the study currently in pre-proof in Additive Manufacturing, the authors have proposed a technique for printing multiceramic materials. This technique uses DLP and has been termed MC-DLP. Suitable for ceramic slurries with high viscosity, the process deposits multiceramic components layer-by-layer. Residual slurries are removed by cleaning and drying to prevent cross-contamination.

Three independent vats of ceramic materials are used in the printing system, allowing the integration of all three ceramics into one component. Different colored slurries with different UV-light curing behaviors were used, with a purple-colored slurry demonstrated to be the most sensitive, whereas the black slurry was the least sensitive.

The authors studied the exposure sequence of a printed multimaterial pattern and proposed a principle for printing based on the exposure sequence. Additionally, the printed parts’ interface qualities were investigated. Different mechanisms were explored. Also, the researchers proposed a method to compensate for precision loss.

Finally, the authors printed and sintered various multiceramic and ceramic-metal components using the proposed technique. Their results demonstrated an excellent capacity for printing highly flexible multiple integrated materials using the method in the research. The authors have stated that, due to the growing demand for high precision miniaturized functional devices incorporating multiple materials, their proposed 3D multiceramic material printing system will play a role in multiple fields in the future.

Further Reading

Hu, K et al. (2022) High-resolution multiceramic additive manufacturing based on digital light processing [pre-proof] Additive Manufacturing 102732 | sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/abs/pii/S2214860422001312

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.