To investigate strategies for creating antimicrobial silicon rubber, a team of scientists writing in the journal ACS Applied Polymer Materials has developed a tough hydrogel coating. The research has the potential for manufacturing safer materials for medical catheters.

Study: Tough Hydrogel Coating on Silicone Rubber with Improved Antifouling and Antibacterial Properties. Image Credit: Sadovnikova Olga/Shutterstock.com

Silicon Rubber Catheters

Silicon rubber catheters are widely used in medicine and possess excellent chemical stability, mechanical properties, biological inertness, and are non-irritating and non-toxic. They can be used for both temporary and long-term surgical applications such as implants.

However, silicon rubber suffers from various drawbacks. This material possesses a highly hydrophobic surface that can absorb proteins, some cells, and bacteria, leading to issues such as inflammation, thrombosis, and infection. Silicon rubber catheters can suffer from biofouling and biofilm formation.

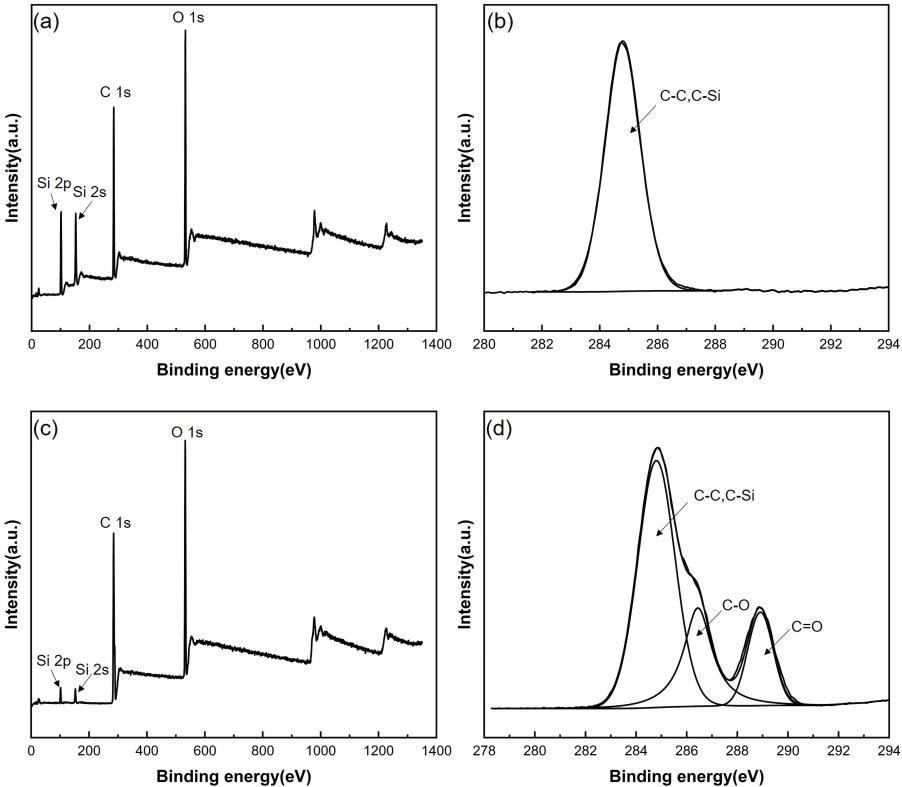

(a and b) XPS wide-scan and C 1s core-level spectra of the pristine silicone rubber surface, (c and d) XPS wide-scan and C 1s core-level spectra of the PVAc coating. Image Credit: Cheng, L et al., ACS Applied Polymer Materials

Improving the Antimicrobial and Antifouling Properties of Silicon Rubber

Improving the antibacterial and antifouling properties of silicon rubber is integral to ensuring that medical devices are safer for patients. In the case of implants, especially, constructing devices out of antibacterial silicon will reduce the risk of long-term infection and the need to remove devices and replace them.

Strategies for improving these properties include surface hydrophilic modification and anti-microbial coatings. Surface hydrophilic modification involves directly introducing hydrophilic hydroxyl groups via processes including ultraviolet light and oxygen. This ameliorates the material’s antifouling properties and is efficient but transitory.

Coating or impregnating silicon rubber with antimicrobial substances provides an easy method for reducing the risk of microbial infection. Whilst this is highly effective, catheters treated with this method can only be used for short-term applications.

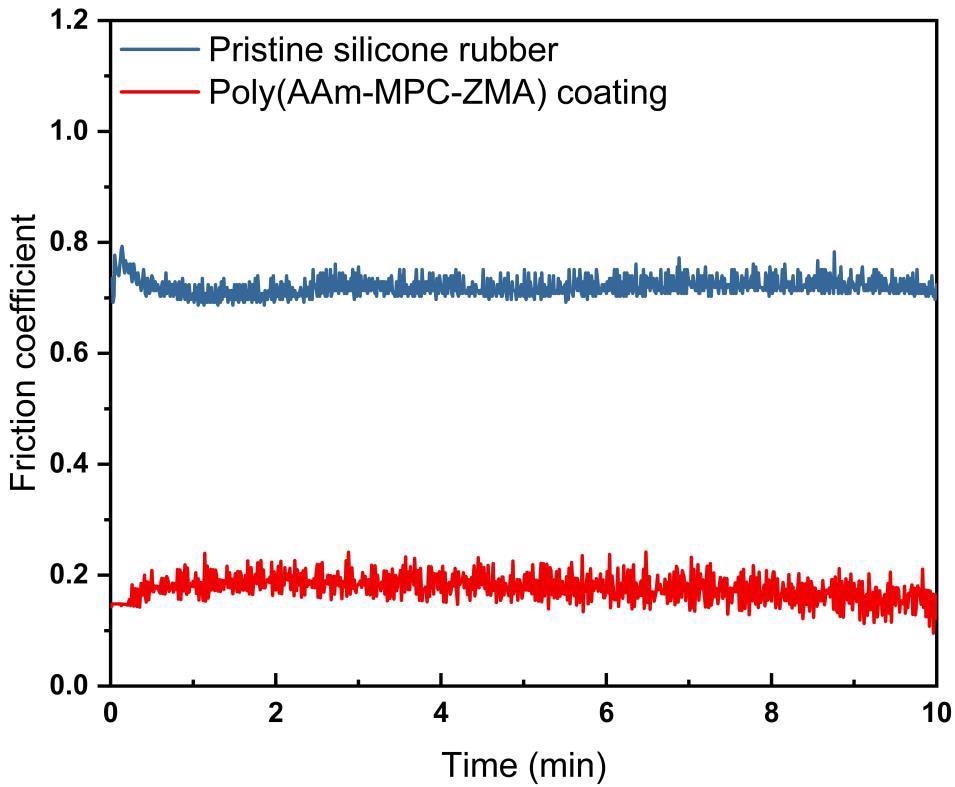

The continuous friction test of silicone rubber before and after being coated with the poly(AAm-MPC-ZMA) hydrogel. Image Credit: Cheng, L et al., ACS Applied Polymer Materials

Using Hydrogels

Hydrogels possess the potential to improve medical devices. Hydrogel-coated substances can improve biocompatibility, lubrication, and antifouling properties. Moreover, the original properties of the coated substance are not affected, such as stiffness, mechanical strength, and toughness.

A key factor in producing suitable hydrogel-coated substances is to construct a strong connection between the material and the hydrogel coating. Silanization can be used to covalently bond the surface of the material and the coating, or a strong connection can be achieved by grafting the hydrogel onto the surface using a benzophenone-initiated reaction.

Recently, another method has emerged: “painting” the surface of the material with a polymer that contains functional groups. Chemical bonds anchor the polymer to the substrate, and a hydrogel is formed via a curing process. Recent research has enhanced the bonding between coating and surface by introducing a poly(vinyl acetate) layer as an interface. Despite recent advances, however, fabricating hydrogel-coated silicon rubber catheters with antibacterial and antifouling properties is still challenging.

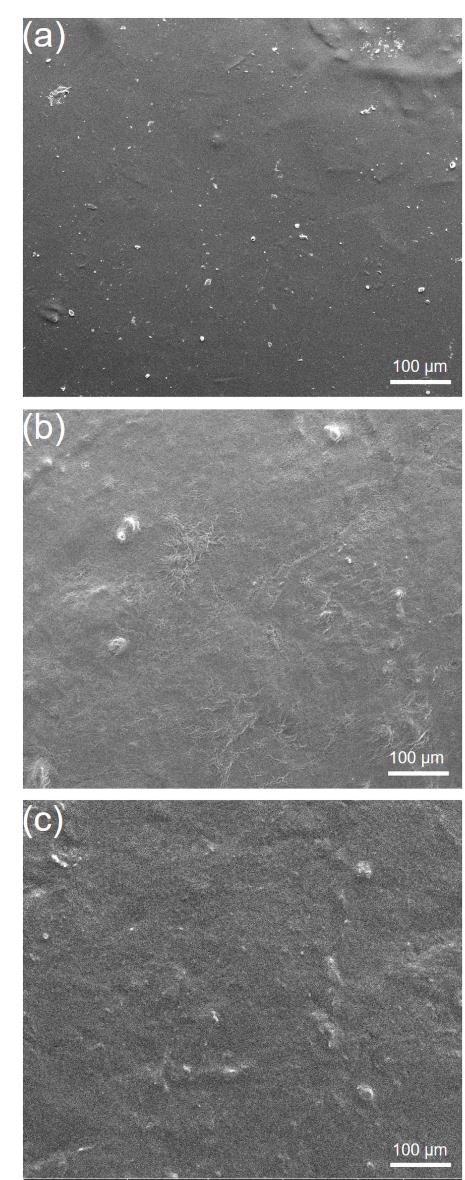

SEM images of the (a) initial poly (AAm-MPC-ZMA) hydrogel coating, (b) poly (AAm-MPC-ZMA) hydrogel coating after 3 cycles of the test, and (c) poly (AAm-MPC-ZMA) hydrogel coating after 10 cycles of the test. Image Credit: Cheng, L et al., ACS Applied Polymer Materials

The Study

The authors have developed a method for grafting hydrogels onto the surface of silicon rubber catheters to imbue them with improved antibacterial and antifouling properties, providing vast potential for the manufacture of safer temporary medical devices and long-term implants.

An ultraviolet light-initiated process was used to graft the hydrogels. The hydrogels were derived from acrylamide, zinc methacrylate, and 2-methacryloxyethyl phosphorylcholine. Zinc methacrylate was chosen for its antibacterial properties and 2-methylacryloxyethyl phosphorylcholine, a zwitterionic monomer, enhanced the antifouling properties of the prepared hydrogels.

A poly(vinyl acetate) primer layer was used in the method to enhance the bonding between substrate and hydrogel. Additionally, the researchers improved the mechanical strength of the hydrogel coating by introducing PnaAMPS gel particles. Tensile tests were performed both with and without incorporated PnaAMPS gel particles.

X-ray photoelectron spectroscopy was used to characterize the prepared hydrogel-coated silicon rubber, and a 90o peeling test was performed to test the hydrogel coating’s interface combination strength. Contact angle analysis was used to evaluate the coated material’s hydrophilicity. Furthermore, the material’s nonspecific protein absorption was tested using bovine serum albumin.

Three bacterial strains, E. Coli, P. aeruginosa, and S. aureus were tested to evaluate the material’s antibacterial properties. Finally, as a preliminary evaluation of the real-life application potential of the novel hydrogel-coated silicon rubber, the authors prepared a silicon rubber catheter and assessed its adhesion against soft biological tissues.

In the preliminary test, the hydrogel-coated rubber was compared with a pristine catheter. Friction was evaluated using pork tissue by drilling two identical holes into the flesh and inserting both the pristine and the hydrogel-coated catheters. A spring dynamometer was used to estimate the catheter’s sliding friction force. Additionally, the surface friction coefficient of both catheters was evaluated. In both cases, the hydrogel-coated catheter caused less friction than the pristine one due to its lubricating characteristics.

Results indicated that the hydrogel coating improved the hydrophilicity of silicon rubber and reduced the deposition of albumin. The hydrogel released Zn2+ ions, which successfully killed the three bacterial species tested. Moreover, the novel hydrogel-coated rubber displayed superior cytocompatibility. Thus, the authors concluded that the hydrogel-grafted silicon rubber has good antibacterial and antifouling properties and can be considered for improved medical catheters.

Further Reading

Cheng, L et al. (2022) Tough Hydrogel Coating on Silicone Rubber with Improved Antifouling and Antibacterial Properties [online] ACS Appl. Polym. Mater. | pubs.acs.org. Available at: https://pubs.acs.org/doi/10.1021/acsapm.2c00069

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.