Writing in the journal Materials, scientists have investigated the simultaneous recycling of spent mushroom waste and electric-arc furnace dust to help realize the aims of the circular economy and reduce the carbon emissions associated with the processing of electric-arc furnace dust.

Study: Spent Mushroom Substrate and Electric Arc Furnace Dust Recycling by Carbothermic Reduction Method. Image Credit: Miriam Doerr Martin Frommherz/Shutterstock.com

Recycling Spent Mushroom Substrate Waste

Environmental impact from human activities has become a key concern in the 21st century. Greenhouse gas emissions from energy generation, industry, and fuel production are causing global temperatures to rise, and vast amounts of industrial waste and pollution are causing increasing damage to ecosystems, biodiversity, and human health.

Spent mushroom substrate waste is generated by the agricultural industry. This waste stream is bulky and has a high water content, which makes transportation challenging. In Taiwan alone, over 300,000 tons of spent mushroom substrate waste is generated annually. Composting is the main disposal and reuse method for spent mushroom substrate, as well as landfilling.

Incineration is a main disposal method for agricultural and domestic waste but is problematic for this type of waste. This is mainly due to plastic packaging and fertilizers used in the production of mushrooms. Chlorine can be present in spent mushroom substrates, which releases PM 2.5 and dioxin, a potent carcinogenic, during incineration. Strict government regulations govern the disposal of waste in incinerators, making disposal by incineration impossible for this waste stream.

Therefore, due to the difficulties with disposal and the potential environmental damage from this common agricultural waste, research has focused on alternative uses for it in line with the concept of the circular economy, where waste streams are recovered, recycled, and turned into value-added products for industrial activities.

Some uses for spent mushroom substrate explored in recent years include using it as a soil additive, power generation, and using mushroom substrate biochar for heavy metal removal from contaminated soils. Another potential use for this waste is as a replacement for coke as a reducing agent in industrial processes, but this method has been largely unexplored.

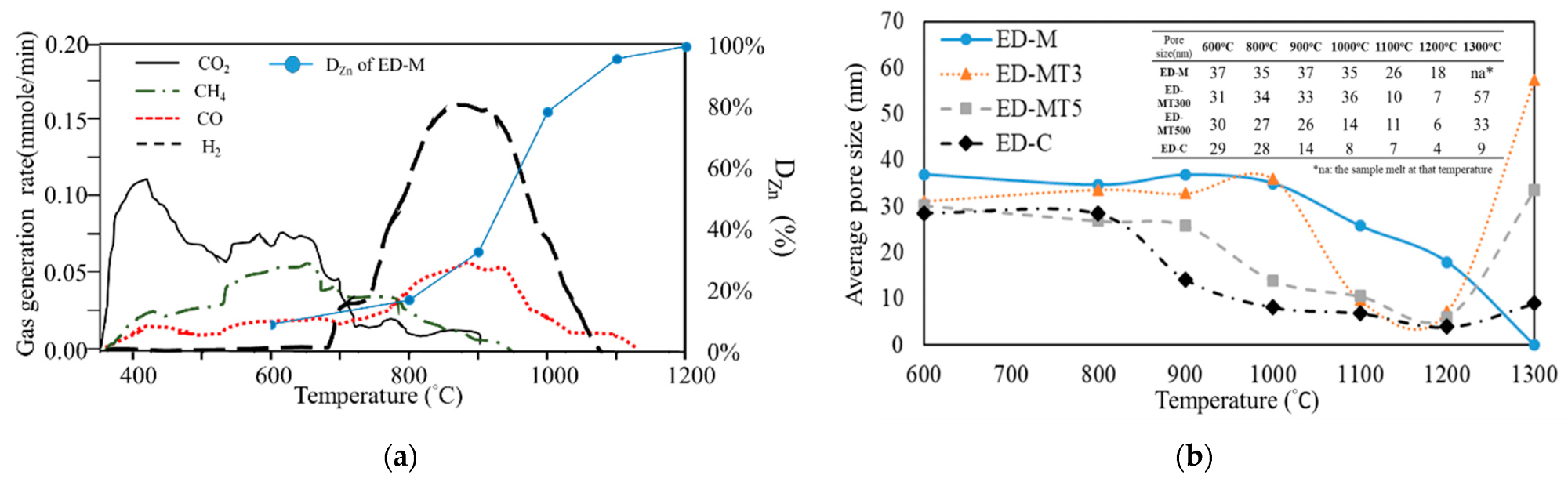

(a) Different types of gases vaporized or dissociated from volatile matter (VM) of SMS which was heated from 300 to 1200 °C at the rate of 20 °C/min in inert gas; for comparison, the degree of Zn removal (DZn, %) is also plotted. (b) Changes in mean pore size in the carbothermic reduction process from 600 °C to 1300 °C of samples with C/O ratio = 0.8. Image Credit: Chang, H-H et al., Materials

Electric-Arc Furnace Dust

Electric-arc furnace dust is classified as toxic waste due to the presence of impurities such as chlorine, lead, and chromium. This waste product, which is a by-product of steel processing, can contain magnetite and franklinite, and due to its toxic nature, electric-arc furnace dust requires special handling, and regulations govern its disposal.

A common method for processing electric-arc furnace dust is the Waelz process. This is a carbothermic reaction where, along with metallurgical coke and/or coke being used as reducing agents, SiO2 and CaO are used as additives to reduce zinc in electric-arc furnace dust. This process uses oxygen, and the reduced zinc is released as a gas. Reoxidation converts the gas to ZnO powder. Other elements become slag.

Utilizing biomass can reduce the economic costs of electric-arc furnace dust processing and recycling. However, the high water content, poor uniformity, and low energy density of spent mushroom substrate presents challenges for using it as a sustainable and cost-effective reducing agent.

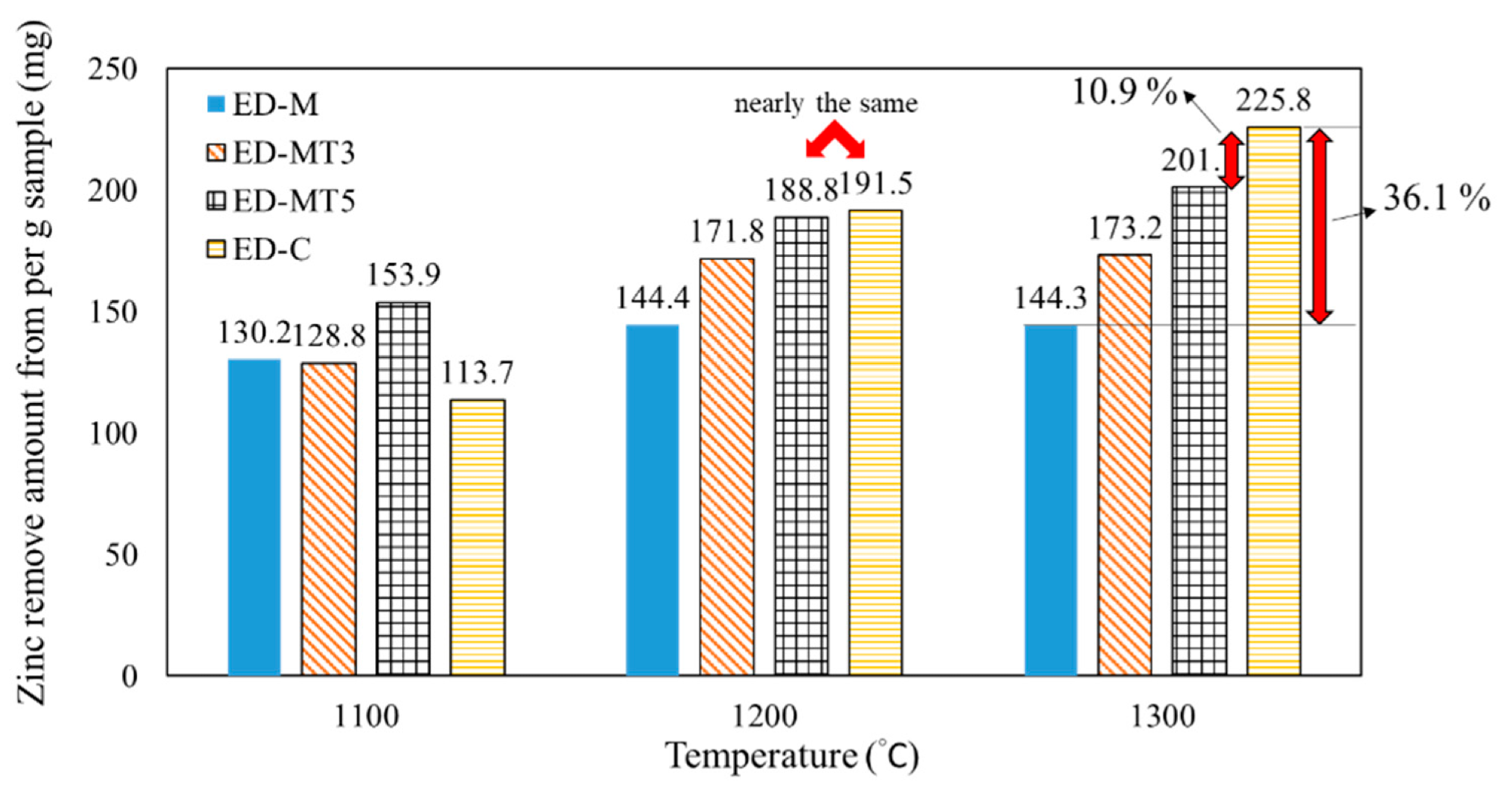

Zn productivity (C/O ratio = 0.8) per gram SMS-based and coke-based pellet samples at different interrupted temperatures (1100 °C, 1200 °C, and 1300 °C) for carbothermic reduction. Image Credit: Chang, H-H et al., Materials

The Study

Writing in the journal Materials, a team of researchers from Taiwan has explored the use of spent mushroom substrate as a reducing agent in the processing of electric-arc furnace dust. This method has advantages for industry: the reduction of harmful greenhouse gas emissions from the use of fossil fuels as reducing agents, reducing costs associated with metallurgical coke use, and the value-added reuse of critical agricultural wastes.

The authors compared the fixed carbon molar ratio and torrefaction temperature of spent mushroom waste and coke to reveal the effects of volatiles in mushroom substrate biomass. Thus far, there has been a lack of study on the effect of volatile compounds in biomass on zinc reduction.

Torrefaction is a process that can overcome the drawbacks of using spent mushroom substrate biomass for this purpose, and increases in the specific energy density and fixed carbon content of biomass have been reported by increasing torrefaction temperature.

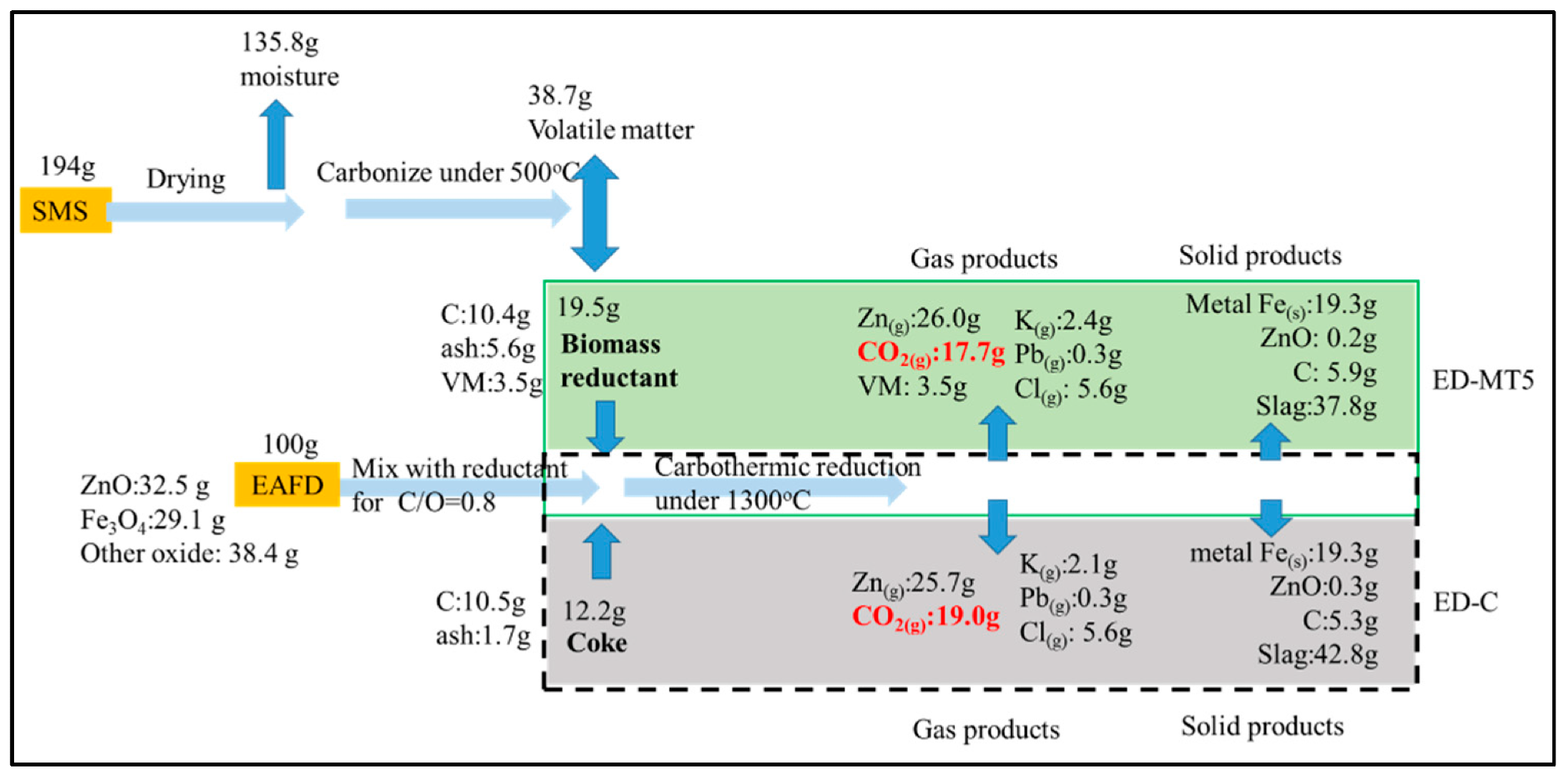

Material flow analysis of ED-MT5 and ED-C as EAFD reducing agents (C/O = 0.8, 1300 °C) and their effects on carbon emissions. Under almost the same Zn products, biomass samples produced less CO2 than coke samples. Besides, the biomass reductant showed the potential for extra carbon-reducing according to the assumption of carbon neutrality. Taiwan needs to process 120,000 tons of EAFD annually. If this method is adopted, 23,000 tons of CO2 emissions will be reduced, creating a channel to process 230,000 tons of SMS annually. Image Credit: Chang, H-H et al., Materials

Results of the study demonstrated a reduction in temperature using spent mushroom substrate biomass as a reducing agent, with the reaction 150 oC lower than using metallurgical coke. Hydrogen, a volatile substance present in the mushroom substrate, assisted in the removal of zinc, with a removal rate of 95%. Zinc removal was observed to be as high as 98% under specific conditions.

Finally, the process is an environmentally friendly one, as the use of spent mushroom substrate not only removes a globally produced agricultural waste stream but significantly reduces the CO2 emissions associated with metallurgical coke use for processing electric-arc furnace dust. This is in line with the aims of the circular economy and international agreements on decarbonizing industry and society.

Further Reading

Chang, H-H et al. (2022) Spent Mushroom Substrate and Electric Arc Furnace Dust Recycling by Carbothermic Reduction Method [online] Materials 15(7) 2639 | mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/7/2639

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.