By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 7 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 7 2022In an article recently published in the open-access journal Energies, researchers presented the utility of protective face mask pyrolysis to manage plastic waste for energy recovery during the COVID-19 pandemic.

Study: Plastic Waste Management towards Energy Recovery during the COVID-19 Pandemic: The Example of Protective Face Mask Pyrolysis. Image Credit: Oleksii Synelnyko/Shutterstock.com

Background

The severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) virus's introduction and rapid dissemination resulted in a surge in demand for personal protective equipment. As a result of this state of affairs, there has been a tremendous increase in the amount of plastic garbage. The pandemic has also had a negative influence on the economy and the ability of local governments to function properly.

The virus's global spread poses significant problems to economies, public finances, and health systems, with the possibility of a recession looming. Since the outbreak of the pandemic, the demand for personal protective equipment (PPE) has skyrocketed over the world.

Because of the growing demand for PPE, massive volumes of plastic trash have been generated. Due to its high calorific value, plastic waste can be a valuable fuel, as evidenced by the research review. During the pandemic, disposable face masks accounted for a large portion of the plastic waste stream. Considering all of the new challenges that may occur in the recycling of PPE, the thermal transformation process is one of the most effective methods of disposal. Pyrolysis, which can be a potential route to sustainable waste management, is one of the most promising ways of thermally converting solid municipal garbage, including plastic trash, as noted in the literature.

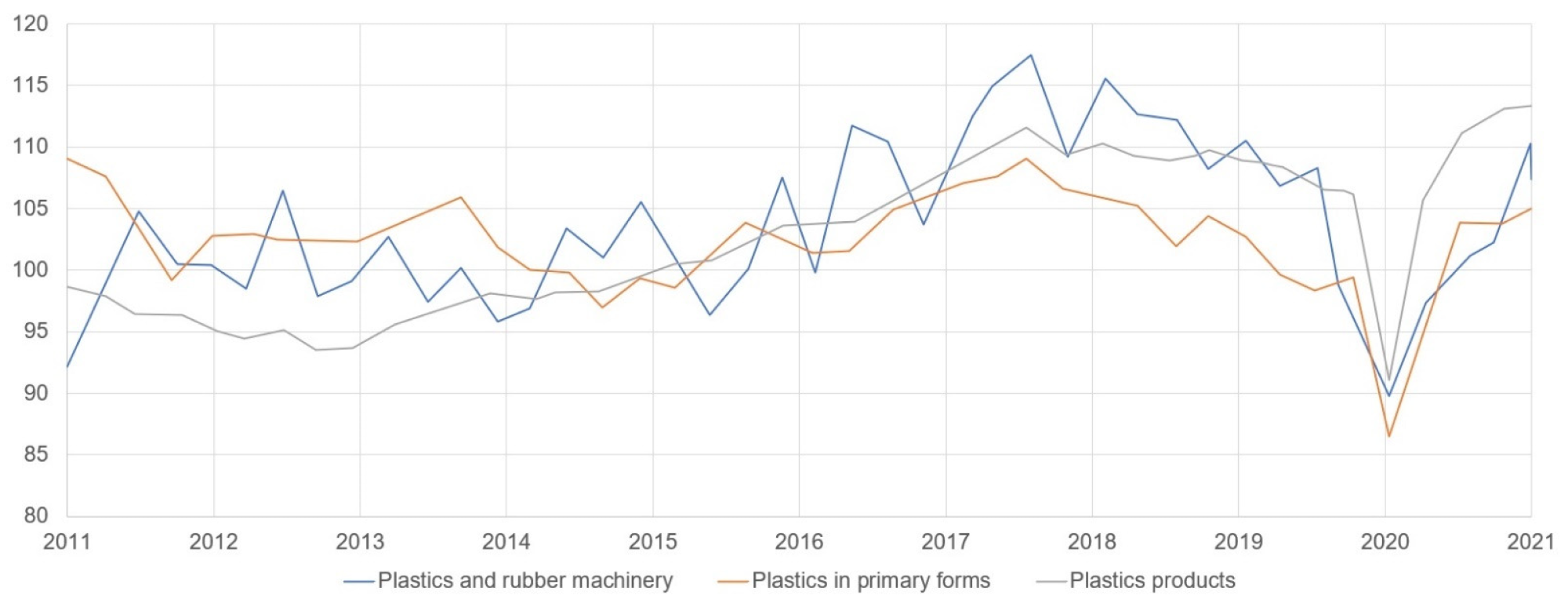

Plastic industry production in EU27 (index 2015 = 100, seasonally adjusted quarterly data). Image Credit: Skrzyniarz, M et al., Energies

About the Study

In this study, the authors examined the influence of the COVID-19 pandemic on the waste management industry and then suggested how to successfully manage selected garbage generated during the pandemic, based on laboratory testing and computer calculations.

As part of the laboratory experiments, the chemical compositions of H, N, S, C, Cl, and O were determined, and the pyrolysis processes of the aforesaid wastes were investigated using the thermogravimetric analysis (TGA) technique. The calculations were carried out using a small pyrolysis reactor with a constant flow rate of 240 kg/h and temperatures ranging from 400 to 900°C. For the conditions of the refuse-derived fuel (RDF) pyrolysis process, the constructed calculation model was experimentally tested.

The researchers presented comprehensive knowledge about the pyrolysis of protective masks based on laboratory studies and computer simulations, with a focus on the gaseous products of this process.

The team determined the impact of the COVID-19 pandemic on the waste management industry and tried to find an efficient way to manage specific garbage generated during the pandemic. The total moisture and ash content of the examined materials were assessed via proximate analysis. An elemental analyzer was used to determine the compositions of Hta, Na, Sta, Cta, and Ota in the studied protective mask material. Gases such as CO2, H2O, N2, and SO2 were identified using a thermal conductivity detector (TCD). Low SO2 concentrations were investigated using a nondispersive infrared (NDIR) detector. The oxygen concentration was quantified using sample pyrolysis at 1120–1150 °C in a reductive atmosphere free of CO2, H2O, and O2. A potentiometric approach was used to determine the chlorine content of the sample.

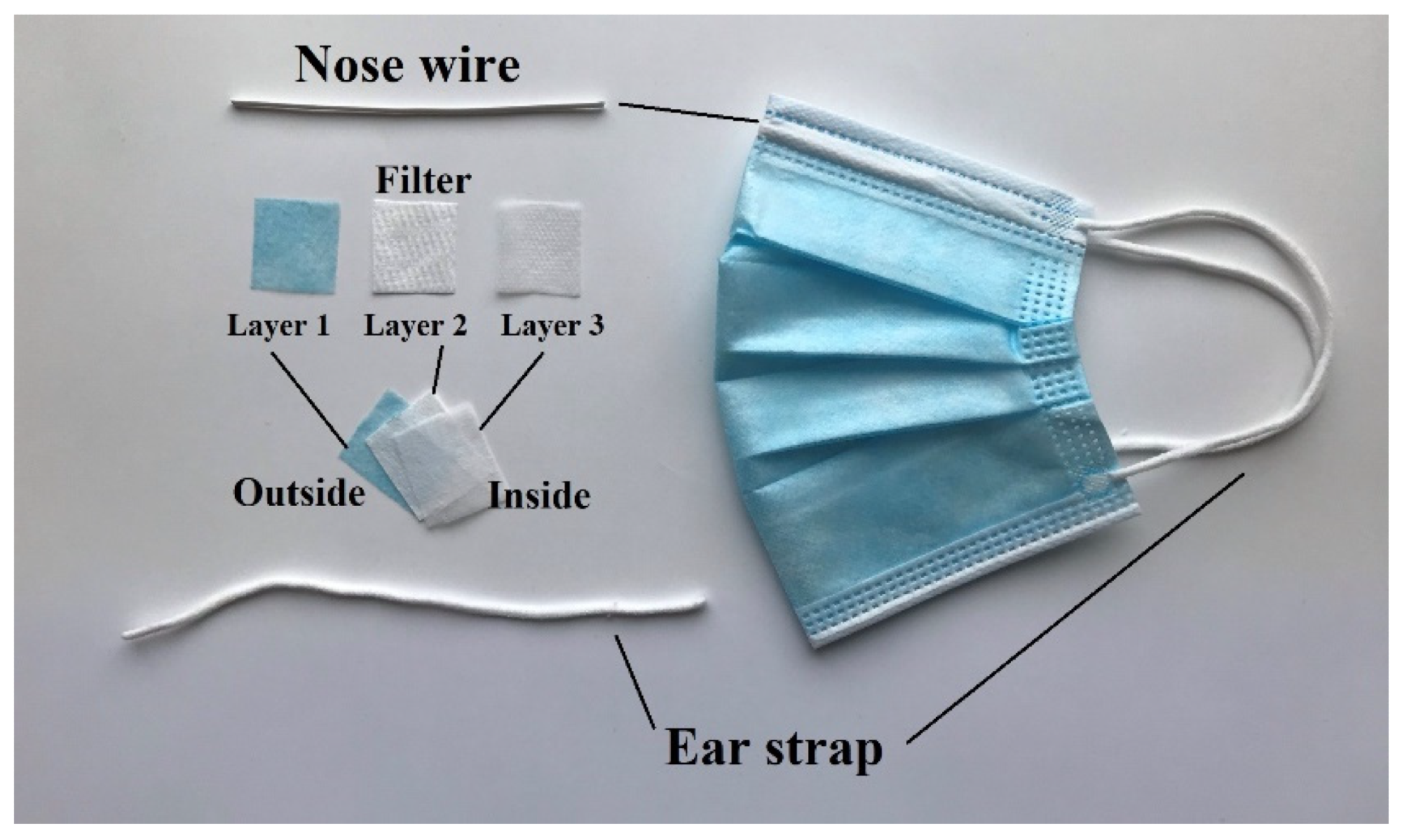

View of disposable protective mask used for studies. Image Credit: Skrzyniarz, M et al., Energies

Observations

A substantial proportion of hydrogen, i.e., 50%, was evident in PP and protective masks, although only at lower temperatures, i.e., 400°C to 500°C. The H2 content in the masks dropped to 15%, and the PP concentration dropped to 22% at 700°C. The CH4 concentration increased in proportion to the increase in process temperature and reached a concentration of around 35% for both masks and PP at 700°C. When the temperature was increased, the concentration of C4H4, C3H8, and C2H2 decreased sharply for all wastes.

Pyrolysis of COVID-19-related plastic waste was found to be a cost-effective and environment-friendly option with a wide range of applications. Pyrolysis could be characterized by a large production of high-calorific pyrolysis gas during thermal waste conversion. This gas had the potential to be used as a natural gas alternative for energy generation.

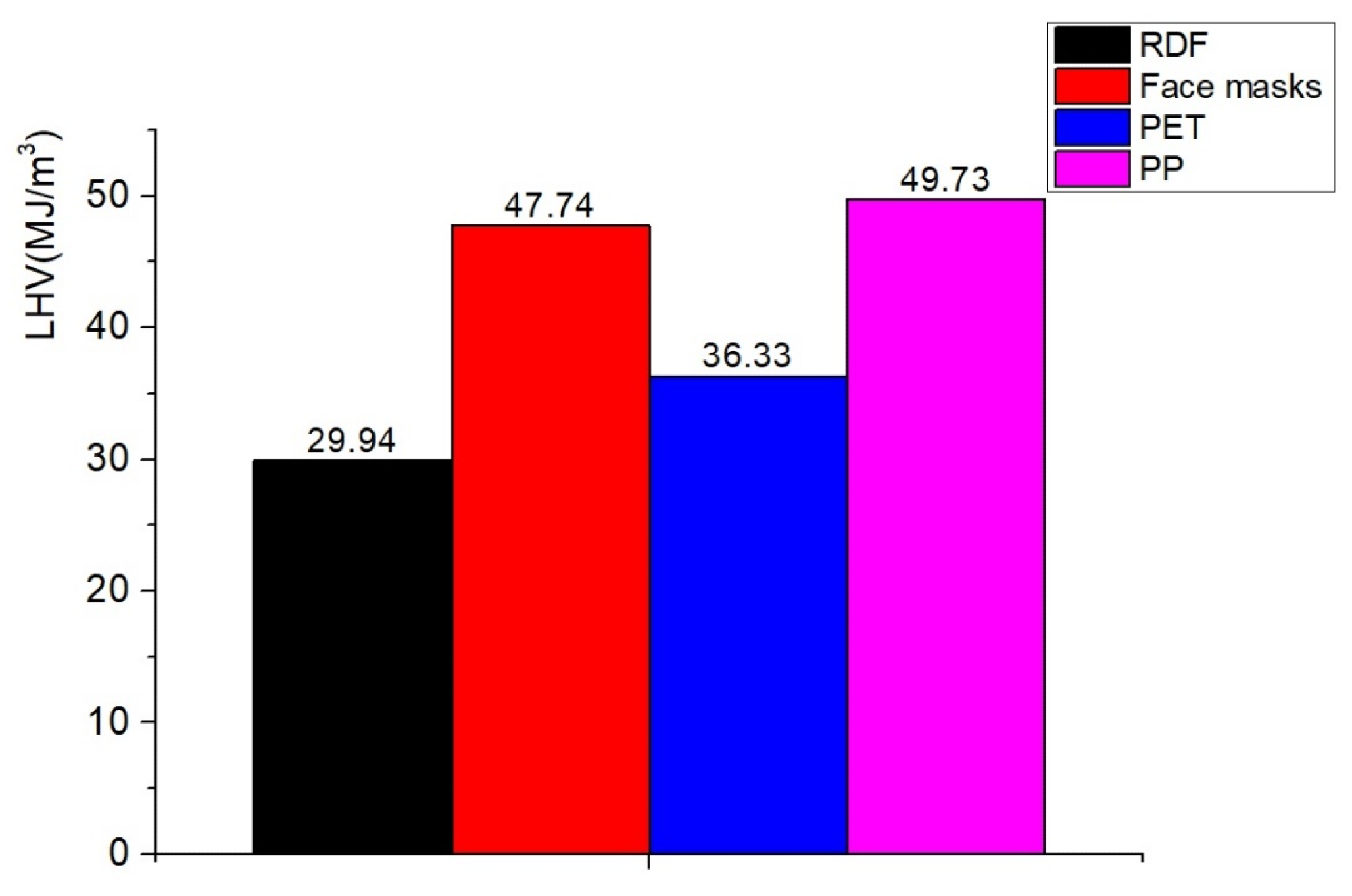

On this basis, the chemical composition of the gaseous products of the pyrolysis of plastic waste could be predicted, and the calorific value of the pyrolysis gas generated in the process could be estimated. During the pyrolysis of polypropylene, the major component of protective masks, produced high-calorific pyrolysis gas (47.7 MJ/m3), with H2, CH4, and C6H6 as the main components.

Calorific value of gas from pyrolysis of selected waste. Image Credit: Skrzyniarz, M et al., Energies

Conclusions

In conclusion, this study elucidated that the pyrolysis gas' high calorific value, at 47.7 MJ/m3, encourages the management of plastic trash toward energy recovery. The findings of the study and computer simulations revealed that plastic garbage, particularly that generated during the COVID-19 pandemic, has a huge energy value.

The authors emphasized that the proposed method could be useful in determining the feasibility of extracting energy from garbage based on its elemental makeup, as well as assessing the environmental consequences. They believe that the proper disposal of this new type of garbage is a technological as well as a material concern.

They also mentioned that solving this problem and developing technological solutions and know-how will allow for the safe treatment of municipal garbage in the COVID-19 era, as well as the appropriate management of thermal conversion products.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Skrzyniarz, M., Sajdak, M., Zajemska, M., et al. Plastic Waste Management towards Energy Recovery during the COVID-19 Pandemic: The Example of Protective Face Mask Pyrolysis. Energies 15(7) 2679 (2022). https://www.mdpi.com/1996-1073/15/7/2629