Reviewed by Alex SmithApr 25 2022

The significantly improved safety and even more interoperable interface characteristics of solid-state electrolyte (SSE) compared to flammable, volatile traditional liquid electrolyte makes it a promising candidate in next-generation lithium (Li) metal batteries (LMBs) applications.

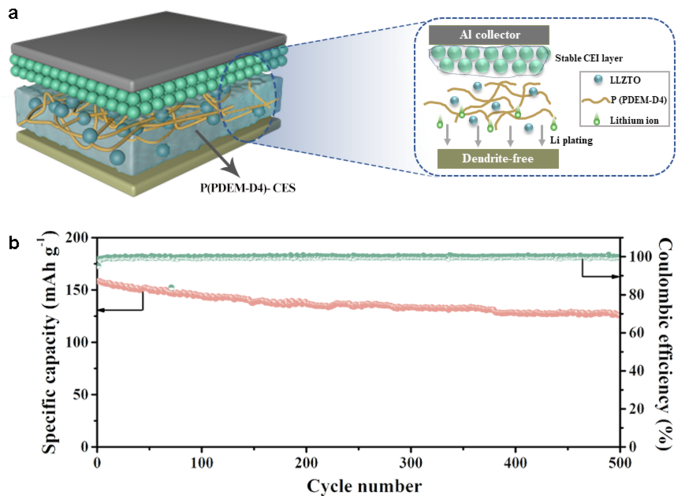

Schematic diagram of CSE design and cycling performance of the as-assembled 4.4 V-class LiCoO2/Li metal battery. Image Credit: ©Science China Press

Schematic diagram of CSE design and cycling performance of the as-assembled 4.4 V-class LiCoO2/Li metal battery. Image Credit: ©Science China Press

Composite solid electrolytes (CSEs) combine the advantages of inorganic solid-state electrolytes and solid-state polymer electrolytes to make them more feasible for commercial applications.

However, only a few attempts have yielded high-voltage (>4.3 V vs. Li/Li+) LMBs with outstanding overall performance, which is largely due to the difficulty in obtaining CSEs with both high ionic conductivity and good electrode compatibility.

Moreover, the relatively time-consuming fabrication process, like ex-situ solution casting with noxious organic solvents, is unlikely to meet the practical requirements of large-scale commercial production.

Professor Guanglei Cui has recently developed a new CSE [dubbed P(PDEM-D4)-CSE] that consists of a star-shaped siloxane-based electrolyte and LLZTO ceramic filler.

P(PDEM-D4)-CSE was produced by facile in-situ polymerization of the electrolyte precursor solution comprising poly(ethylene glycol) methyl ether acrylate (PDEM), 2,4,6,8-tetramethyl-2,4,6,8-tetravinylcyclotetrasiloxane (D4), lithium difluoro(oxalate)borate (LiDFOB), and LLZTO particles.

D4, as a component of the polymer backbone, can greatly enhance the free volume for polymer chain segmental motions, thereby improving ionic conductivity. As a Li+ carrier, PDEM provides Li-ion transport channels. LiDFOB, as the Li source, provides Li+ and DFOB–, as well as participating in the interface film construction.

As an active ceramic filler, LLZTO not only improves the segmental motion of the polymer matrix by lowering crystallinity and increasing the free volume of the polymer matrix, allowing more channels for ion transport to be built, but it also acts as an anionic receptor, promoting the dissociation of Li salts and increasing free Li-ion concentration.

Ionic conductivities of P(PDEM-D4)-CSE is high (4.0 × 10−5, 1.68 × 10−4, and 5.73 × 10−4 S·cm−1 at 30 °C, 60 °C and 100 °C, respectively). Moreover, due to the formation of a compatible solid electrolyte interface, this CSE can stimulate more uniform, reversible Li plating/stripping behaviors.

As a result, the as-developed CSE facilitates long-life 4.4 V-class solid-state LMBs based on a LiCoO2 cathode that delivers 79.7% capacity retention and 99.74% average Coulombic efficiency after 500 cycles at a 0.5 C rate.

Journal Reference:

Wang, Q., et al. (2022) An in-situ generated composite solid-state electrolyte towards high-voltage lithium metal batteries. Science China Chemistry. doi.org/10.1007/s11426-022-1221-4.