As there are no properly defined standards for the safe storage and transportation of hydrogen, the latest article in the journal Energies effectively discusses the hazards associated it and compares the transport systems of hydrogen and LPG.

Study: Safety Considerations of Hydrogen Application in Shipping in Comparison to LNG. Image Credit: Scharfsinn/Shutterstock.com

Safety, Risk, and Hazard

Controlling identified dangers to accomplish an appropriate level of risk is the goal of safety precautions. A hazard is defined as a possible cause of damage to individuals, properties, or the ecosystem in accordance with ISO/IEC Guide 51:2014. Risk is defined as the conjunction of the likelihood and the degree of that harm.

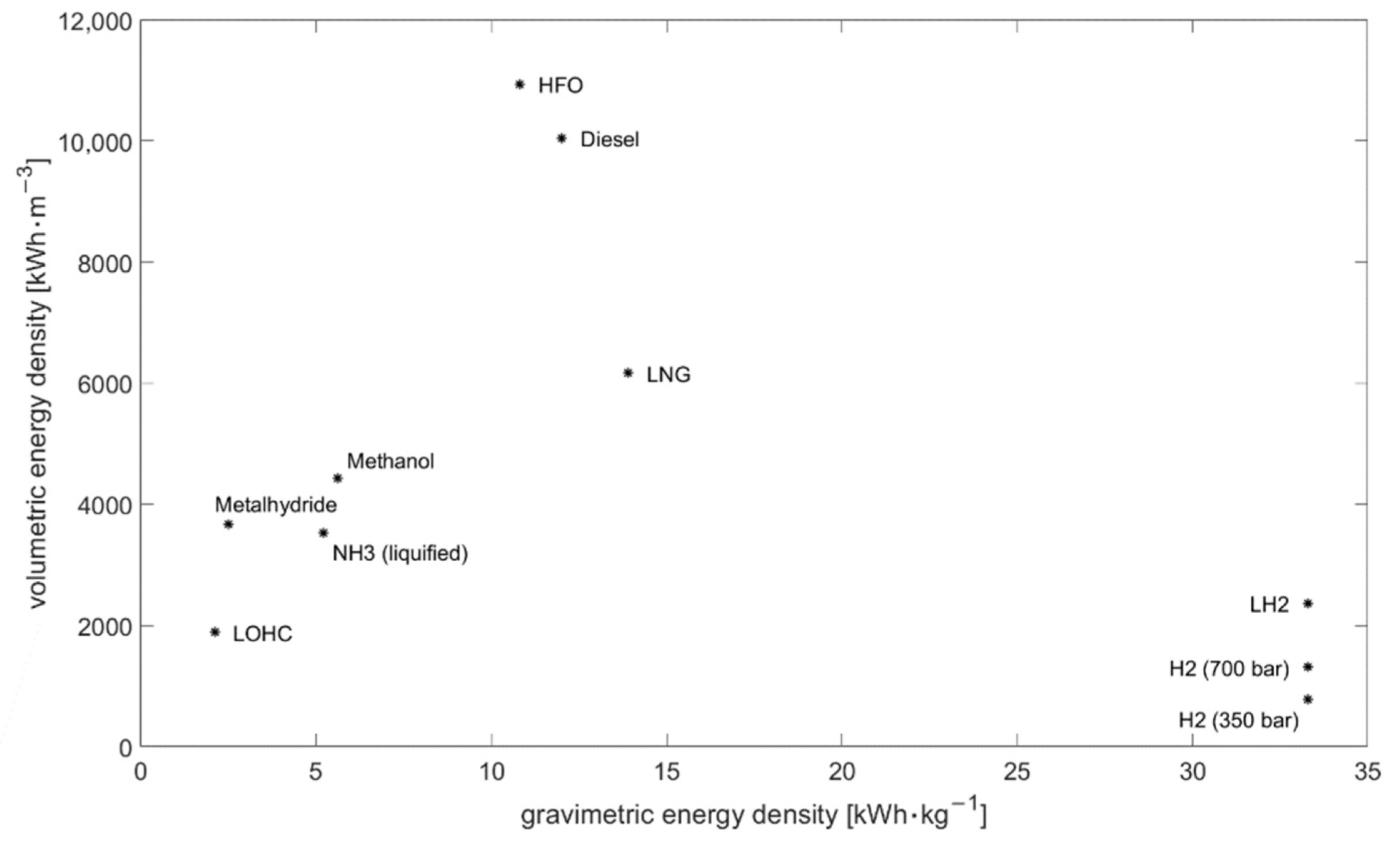

Energy density of different energy carriers. Image Credit: Depken, J. et. al., Energies

Properties Affecting Hydrogen Safety

Hydrogen has a very high specific gravity energy density of 33.3 kWh/kg, but its volumetric energy density is just 3 kWh/m3. Hydrogen's boiling temperature at normal pressure is 20 K, while its melting point is 14 K, both of which are pressure-dependent. Pressures above the vital point of 33 K and 1296 MPa (12.96 bar) do not affect the boiling point. All these properties play an essential role in the safety considerations.

General Hazards Associated with Hydrogen

The most dangerous aspect of hydrogen is its extremely high combustibility. Owing to its wide range of combustible percentages (4-75%), it is sometimes seen as more hazardous than natural gas, which is already commonly utilized in transportation. The autoignition temperature for hydrogen is lower than many other chemicals utilized in transportation, which makes it even more dangerous.

The risk of explosion is a major limitation that affects its transportation. The proportions at which a gas can detonate are listed from the lower explosive limit (LEL) to the upper explosive limit (UEL). As hydrogen has a very broad explosive range, bursting is a very dangerous concern.

Sensors for Hydrogen Detection

There are several types of hydrogen sensors available. According to one research paper, the majority of commercially accessible sensors are electrochemical. The appropriate sensor type must be selected for a certain application in terms of responsiveness, environmental parameters, aging, drift, reaction time, and durability.

Limitations of a particular sensor module may be mitigated by integrating several different types. Power usage, complexity, and expense should all be taken into account. Various sensor types' tolerance should also be addressed.

![Charpy impact strength as a function of temperature for various materials based on [30].](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_58971_16515701718835249.png)

Charpy impact strength as a function of temperature for various materials. Image Credit: Depken, J. et. al., Energies

Hazards Associated with Pressurized Hydrogen Storage

Gaseous hydrogen is often kept in gas containers at pressures ranging from 350 to 700 bar. The collapse of the container, culminating in an uncontrolled discharge of hydrogen, is a risk of pressurized storage.

If a sudden rise in temperature due to fire causes the internal vessel pressure to increase, a thermally triggered pressure relief device (TPRD) can quickly release all of the hydrogen in the container before a breach takes place due to compromised walls.

Are there Ongoing Hydrogen Shipping Projects?

Several initiatives are presently underway across the world to address the issue of sustainability in hydrogen-related marine facilities. The ship "Suiso Frontier" is an initiative of the Hydrogen Energy Supply Chain Technology Research Association" (HySTRA) that began in 2016. It will be used to deliver liquid hydrogen (LH2) from Australia to Japan.

Hydra is headquartered in Stavanger, Norway. It is the world's inaugural hydrogen transport operation. The 82-meter-long ship can transport 80 automobiles and 290 individuals. MAN announced a project on liquid hydrogen fuel-gas-supply systems in Sweden. This mechanism was created in accordance with the IGF Code.

Alternative Design Approach

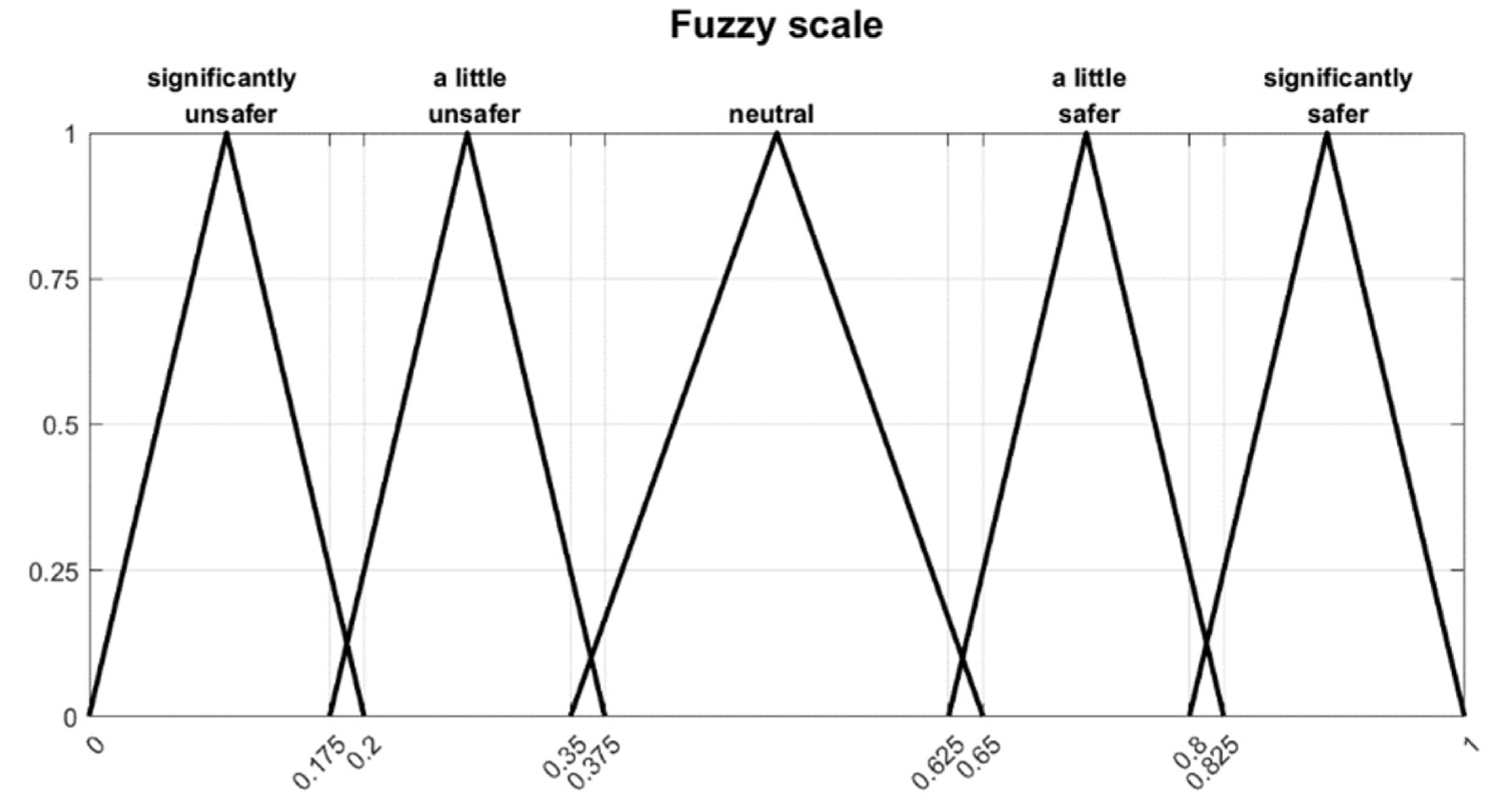

There are presently no hydrogen regulations in transportation, however the alternative design method allows for the authorization of hydrogen equipment. As a first stage, all criteria of the researched system must be determined to make a meaningful comparison. The significance of these factors to protection will then be evaluated using pairwise comparison.

For each criterion stated in a row, it is verified to the criteria stated in the column. When the table is entirely filled, the values in each row are added together. This number can be used to implement a control method. The newly built system is then assessed as a system designed in accordance with existing regulations, such as an LNG system in this situation.

In short, the comparison method with LNG systems will help in the standardization of hydrogen safety rules and enable the safe shipping of hydrogen all over the world.

Fuzzy scale. Image Credit: Depken, J. et. al., Energies

Further Reading

Depken, J. et. al. 2022. Safety Considerations of Hydrogen Application in Shipping in Comparison to LNG. Energies. 15. 3250. Available at: https://www.mdpi.com/1996-1073/15/9/3250

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.