By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 12 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 12 2022In an article recently published in the journal Additive Manufacturing, researchers discussed the printing of highly viscous food by using vibrations.

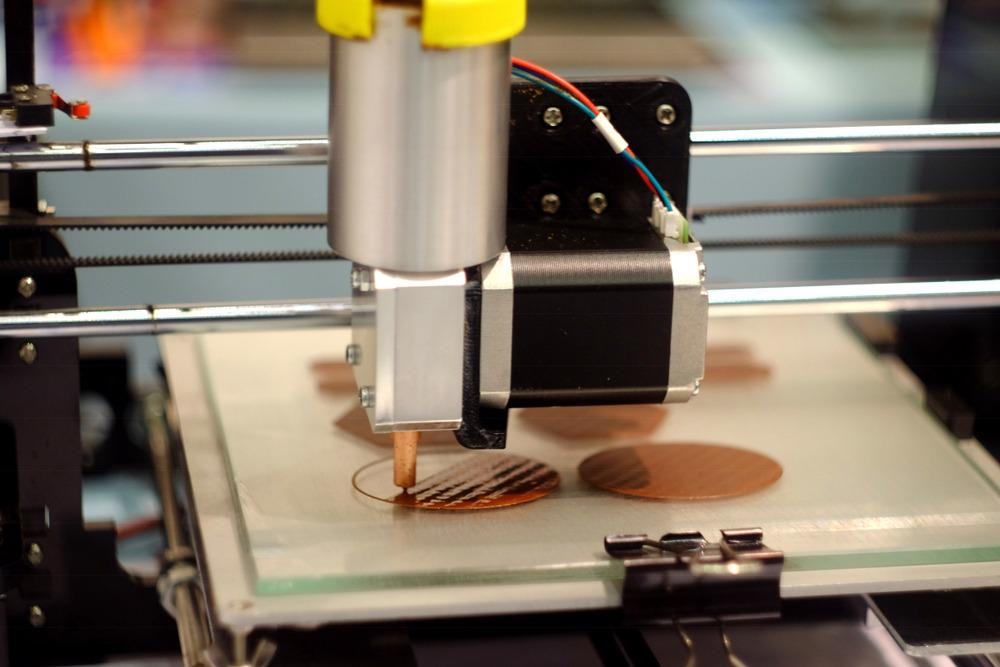

Study: Vibration-assisted printing of highly viscous food. Image Credit: Maksym Kaharlyk/Shutetrstock.com

Background

Over the last three decades, additive manufacturing (AM) has expanded to cover a wide range of prototyping methods. However, similar to other AM technologies, food AM often necessitates food material alterations from more traditional forms in order to attain printability. As a result, the nutritional content and texture are reduced, underlining the need for a new strategy.

To date, much of the work in food printing has been on digital gastronomy applications, emphasizing food 3D printing as a component of custom creative presentation. However, AM's implications are much broader. Despite their shown benefits in a variety of application areas, existing printing technologies are challenged by the complex and unpredictable material qualities of food.

The tendency toward material modification for printability and greater extrusion regions can be seen in recent work in extrusion-based approaches for 3D printing of food. Chocolate has demonstrated good results for hot-melt extrusion 3D printing due to its thermoplastic characteristics. A focus on printability and discovering the processing parameters required to achieve it, rather than nutritional content and texture, is common in the field. Vibration-Assisted Printing (VAP) is a modified direct-write technique that can print high-viscosity materials such as food.

About the Study

In this study, the authors investigated the use of VAP in the additive fabrication of food by printing two high-viscosity dough materials, a model dough and a low-fat, high-protein, high-fiber lentil fiber formulation. A recently introduced AM approach was applied to VAP food printing. VAP worked by employing ultrasonic vibrations to induce slip conditions at nozzle boundaries, which allowed for high-resolution selective deposition of very viscous materials.

The team demonstrated enhanced printing precision and speed with unmodified, normal, and high-viscosity dough by the fabrication of a range of shapes utilizing extremely viscous dough with high solids loading using VAP with in situ process monitoring. With this expanded potential, a high-fiber dough with significant inclusions, such as bran flakes in whole-wheat flour, was printed.

The researchers used two varieties of dough. One that was meant to be rich in nutritional value and one that was indicative of a general, multi-ingredient dough. The model dough was chosen for its model rheological behavior and silky consistency, as well as its more complex formulation. The lentil fiber dough was created with a focus on nutritional value above material consistency, with a high protein, high fiber, and low-fat content. A twin-barrel capillary rheometer was used to measure the viscosity of the lentil fiber dough at 25 °C. The sample geometries were designed in a traditional mechanical CAD program and produced as an STL file. Process parameters were changed, and GCode files were created using the open-source slicing software Slic3r in the Repetier-Host 3D printer interface.

Observations

At the end of the 3.5-hour drying period, the center of the 100% infill samples was still soft and moist, whereas the 0% infill samples were nearly completely dry and hollow, which indicated that the compressive strength was consistent and composite texture varied between samples. The dough's maximum temperature rise during printing was 9 °C above ambient settings, with temperatures normally in the range from 4-6 °C over ambient, which suggested that the ultrasonic vibration at the nozzle could not create significant heating to cause premature cooking.

VAP provided for speedier production with a printing speed of 67 mm/s, required no material change, and delivered excellent geometric precision utilizing a 500 m diameter nozzle. VAP was able to manufacture samples with demonstrated mechanical strength without significant material change and print materials with varied inclusions due to the high solids fraction of the dough. In situ temperature monitoring revealed that VAP only caused minimal temperature rises in the material, which was important for food preparation.

Switchable on/off control was possible since the flow was driven by vibration rather than just by backpressure. This technique was unique in that it could print non-Newtonian materials with high viscosity, such as highly viscous meals, with smaller nozzle diameters and faster print speeds than traditional AM systems.

Conclusions

In conclusion, this study discussed the use of VAP for food additive manufacturing, with the capability to print high viscosity pseudoplastic material. The VAP technique was used to make samples from recipes that are regularly utilized in the food industry. The ability of the technology to print high-protein, high-fiber, and low-fat material was proved using a model dough and a nutritional lentil-based dough.

Using layer heights as low as 400 µm and a 500 µm diameter nozzle, examples with high aspect ratios and steep overhangs were created using the two dough materials, demonstrating the exceptional print quality achievable with more viscous and pseudoplastic dough.

The authors believe that VAP offers an alternative to standard direct-write food printing that works well with high-viscosity and high-solids-loading materials, paving the way for future research into additive manufacturing of high-nutrition foods.

More from AZoM: 3D Printing with Responsive Photopolymerisable Liquid Crystals

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

McCaw, J. C. S., Fleck, T. J., Tejada-Ortigoza, V., et al. Vibration-assisted printing of highly viscous food. Additive Manufacturing 102851 (2022). https://www.sciencedirect.com/science/article/abs/pii/S2214860422002500