By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jun 3 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jun 3 2022In an article recently published in the journal Ceramics International, researchers studied the clays from Alhabia (Almera, Spain) as well as their thermal and ceramic qualities.

Study: Characterization, thermal and ceramic properties of clays from Alhabia. Image Credit: 682A IA/Shutterstock.com

Background

Clays, being the principal raw materials utilized in huge tonnages for the ceramic industries, exhibit unique transformation effects during thermal breakdown that are useful in the development of a variety of higher-value materials. In all prior research, the investigation of physicochemical properties of raw clays through characterization was critical for their manufacturing processes, as processing circumstances influence the final properties of the ceramic bodies.

![General setting and simplified geological of S-SE of Almería province with location of the different Neogene basins (Modified from Braga et al. [23]).](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_59248_16542503798353279.jpg)

General setting and simplified geological of S-SE of Almería province with location of the different Neogene basins.Image Credit: Rat, E et al., Ceramics International

Clay-containing deposits with a wide range of mineralogical compositions are referred to as common clays. New deposits of raw clays must be studied in order to gain a thorough understanding of mineral resources and their applications. Previous research on illite-kaolinitic clays has been done. The research on illite-chlorite-kaolinitic and illite-chlorite clays without carbonates, on the other hand, has received less attention. Also, there hasn't been much research on illite-chlorite clays containing carbonates.

About the Study

In this study, the authors used X-ray fluorescence (XRF), X-ray diffraction (XRD), scanning electron microscopy (SEM), thermal analysis, and energy dispersive X-ray spectroscopy (EDS) to explore clays from Alhabia (Almera, Spain). Plasticity and texture features such as granulometry were investigated. Using pressed and fired clay samples, the main ceramic characteristics such as firing shrinkage, bulk density, water absorption, flexural strength, open porosity, and thermal conductivity were determined. For the first time, the mineralogical, textural, chemical, and ceramic characteristics of these clays were demonstrated.

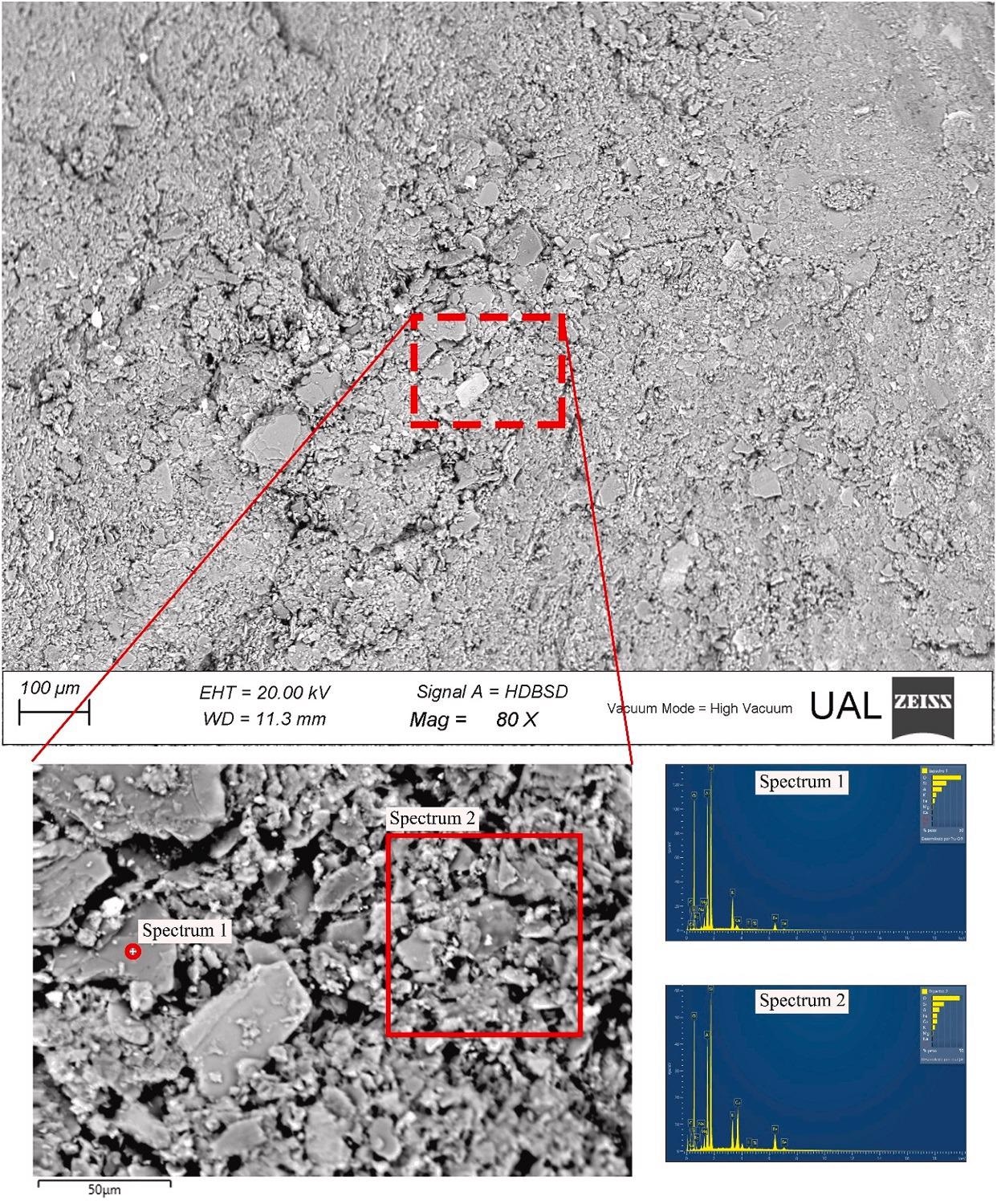

The team determined the ceramic characteristics of blended and ground clays after burning with pressed bodies following the characterization of raw clays. Two firing temperatures of 900 and 1100 °C were used for one hour for this purpose. SEM and EDS were used to validate the morphologies, mineralogical characteristics, and microstructure of the layered silicates, as well as the presence of quartz and calcite crystals. The ceramic characteristics of mixed and ground pressed clay samples were investigated by firing them at 900 and 1100 ºC for 1 hour after soaking.

The researchers characterized and appraised the ceramic uses of clays from the Alhabia clays deposit. It was proposed that the raw clay material could be made via extrusion since it has moderate plastic capabilities and acceptable molding properties.

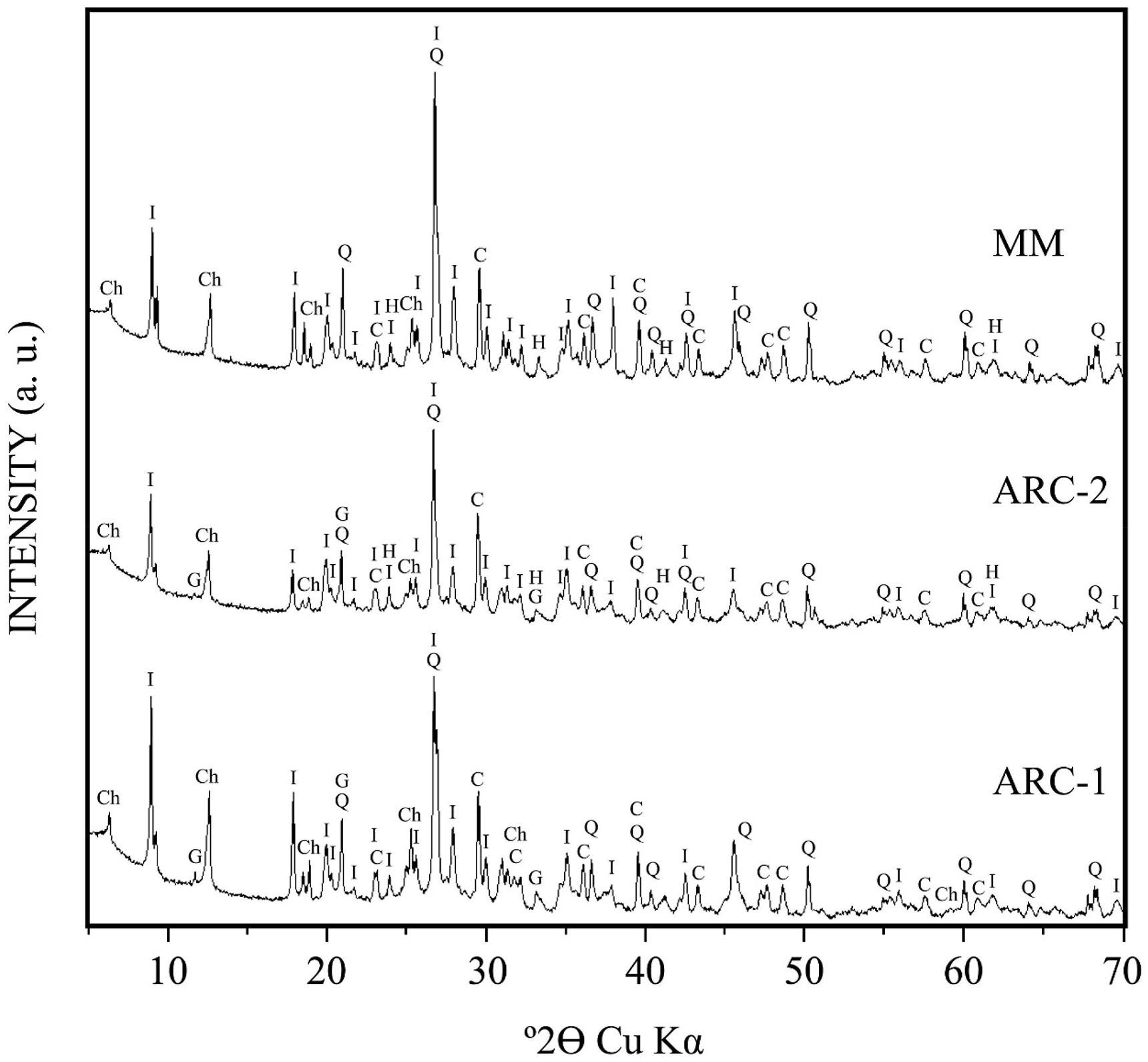

X-ray diffraction patterns of Alhabia clay samples designed as ARC-1, ARC-2 and MM. Ch = Chlorite-serpentine; I = Muscovite-Illite; Q = Quartz; C=Calcite; G = Gypsum; H=Hematite. Image Credit: Rat, E et al., Ceramics International

Observations

The XRD mineralogical examination revealed that the clay samples were made up of a mixture of illite and chlorite as the principal clay minerals, with quartz and other minerals in smaller proportions. The chemical examination by XRF revealed that silica and alumina were the most abundant minerals, as predicted by the mineralogy, with medium quantities of alkalis from illite and calcium oxide from calcite of 5 and 8%, respectively, besides titanium and iron oxides.

The particle size examination revealed a clay fraction of 71.76% and a silt fraction of 21.66%. It was discovered that porous ceramic materials which had 36% open porosity and 22% water absorption capacity could be achieved by firing at 900 °C, with modest differences in dimensions. By fire at 1100 °C, the porosity varied at lower levels, which was linked to the presence of disintegrated calcite. From 900 to 1100 °C, bulk density was found to be nearly constant, with a high of 1.67 g/cm3 at 1100 °C. The ground sample's flexural strength reached a high of 34.47 MPa at 1100 °C. After burning the clay bodies, thermal conductivity was found to be nearly constant at 900 and 1100 °C.

The Atterberg plasticity index was 14.3%, with satisfactory molding and extrusion qualities. The weight loss was linked to dehydroxylation of structural water in clay minerals and decarbonization of calcite by gradual heating. The presence of calcite was linked to the level of calcium oxide. The overall number of alkaline elements in the form of oxides was less than 5%. At 900 and 1100 °C, linear firing shrinkages were very low.

Firing at 900 ºC resulted in porous ceramic bodies. The open porosity changed to lower values after burning at 1100 °C, which was mostly due to calcite breakdown.

SEM-EDS of sample MM. Image Credit: Rat, E et al., Ceramics International

Conclusions

In conclusion, this study elucidated that the principal applications of these clays are in the construction of porous ceramic supports, structural ceramics, and tiles by fire at 900 °C.

The authors emphasized that the findings of this study are of significant importance in gaining a better understanding of this type of clay used as a ceramic raw material. They also mentioned that future research into the production and growth of crystalline phases by firing, sintering mechanism, and microstructural evolution would be of interest. They believe that this research contributes to a greater scientific understanding of chlorite-illite-calcitic clays and their utility as ceramic raw materials.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Sources:

Rat, E., Martínez-Martínez, S., Sánchez-Garrido, J. A., et al. Characterization, thermal and ceramic properties of clays from Alhabia (Almería, Spain). Ceramics International (2022).

https://www.sciencedirect.com/science/article/pii/S0272884222019216