A paper recently published in the journal Energies reviewed liquid hydrogen storage tanks and insulation systems for high-power locomotives.

Study: Review of the Liquid Hydrogen Storage Tank and Insulation System for the High-Power Locomotive. Image Credit: alexfan32/Shutterstock.com

Background

Hydrogen has gained significant attention as a fuel that can help the transportation sector to achieve carbon neutrality. Hydrogen can be stored in a chemical, liquid, or gaseous form. Among these forms, hydrogen stored in liquid form/liquid hydrogen possesses the highest energy density and can be converted easily to hydrogen gas.

Thus, liquid hydrogen is suitable as a fuel for vehicles that have limited space and require enormous power or high speed, such as drones, ships, and locomotives. Moreover, the use of liquid hydrogen can reduce the weight of high-powered vehicles such as locomotives as it has a higher energy density compared to batteries, allowing the loading of more cargo and offering a long mileage.

Hydrogen trains can be effective as long-distance or multiple-unit high-powered locomotives and used as a replacement for existing diesel trains to reduce air pollution, specifically the emission of indirect air pollutants such as carbon monoxide and direct air pollutants such as particulate matter. Hydrogen trains have been studied actively by different companies and research institutions in several countries such as China, the United States (US), and Korea.

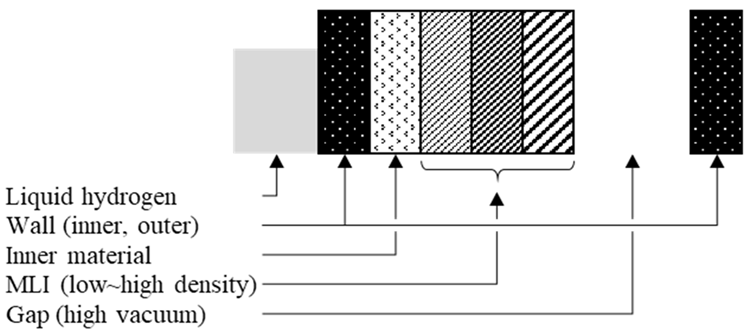

However, the thermal insulation of liquid hydrogen is challenging as it must be stored in a cryogenic state, which necessitates an analytic study of liquid hydrogen tanks. Inner materials, such as vapor-cooled shields (VCS), high vacuum, multi-layer insulation (MLI), and glass bubbles are typically utilized for thermal insulation.

Insulation concept of the multi-purpose hydrogen test bed. Image Credit: Kang, D.et al., Energies

The Study

In this study, researchers performed a literature review for the thermodynamic modeling of liquid hydrogen storage tanks for transportation sector applications. The literature was divided into systematic, dynamic, and static modeling studies.

Static Modeling

Most liquid hydrogen tanks are either integrated with the ships or remain independent from the carrier vehicle during their transportation. Materials that are commonly used to manufacture liquid hydrogen tanks, such as composite materials, titanium and aluminum alloy, and stainless steel, become brittle under cryogenic conditions. Other materials, such as copper, possess a lower insulation effect than steel and can be used for the inner vessel.

Fiberglass, such as G11, G10-CR, and G10, can be utilized for supports and suspension in small-sized stationary tanks, while stainless steel can be used for large mobile tanks, which increases heat leakage. The air layer present in the gap between the outer and inner vessel walls can be configured as heat radiation between solids and heat conduction of gases.

Temperature, pressure, and level sensors connect the outer and inner walls of hydrogen tanks. The outer and wire material of the sensors can be 316L stainless steel and copper, respectively. Polyimide film can be utilized as a shell material to insulate the copper wire.

Spray-on foam insulation (SOFI) is suitable as inner material as the vacuum pressure has little effect on the material, unlike MLI. However, MLI demonstrated a significantly better insulation performance compared to SOFI, while a hollow glass microsphere (HGM) displayed a superior performance than MLI.

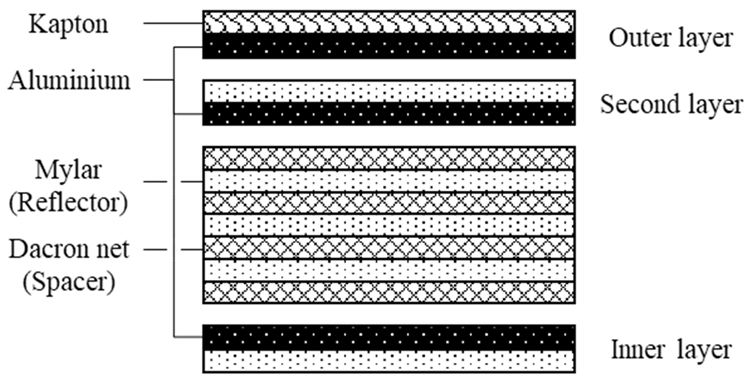

MLI is composed of a spacer with low thermal conductivity and a reflector with low thermal emissivity. Perlite particles and alumina-coated polyester sheets were used for MLI, with Dacron nets and Kapton used as spacers and reflectors, respectively. The spacer thickness can be modified to improve the MLI insulation performance.

Moreover, the combination of MLI and foam displayed a better performance than MLI. The MLI simulation using the semi-empirical formula-based Lockheed model can solve the overall heat flux quickly, while the simulation using the layer-by-layer model based on an iterative algorithm can determine the temperature of every layer in MLI.

The thermal conductivity, critical heat flux (CHF), and heat transfer coefficient (HTC) of hydrogen were investigated in previous studies. For instance, the nucleate flow boiling HTC of liquid hydrogen was summarized, and an artificial neural network was suggested that can derive HTC.

MLI configuration for insulating spacecraft. Image Credit: Kang, D.et al., Energies

Changes Due to Hydrogen Phase Change

The sensible heat of liquid hydrogen is more significant compared to its vaporization heat until the hydrogen attains a gaseous state at an ambient temperature, and the ratio of the two increases with the rising pressure. For instance, the ratio was 23.70 at 1.2 MPa and 7.82 at 100 kPa, and the enthalpy changed by 3860 kJ/kg during the vaporization from –253 to 20 oC.

Although the vaporization heat of liquid hydrogen was inadequate to cool the fuel cell, it helped in insulating the liquid hydrogen tank. Moreover, the vaporization expansion ratio of the liquid hydrogen was 848, implying that 100 kPa of liquid hydrogen can be vaporized to 172 MPa of vapor hydrogen, which is substantially higher than the gaseous hydrogen pressure of 300 kPa–1.6 MPa in typical vehicle fuel cells. Thus, effective pressure control is necessary from the vessel to the fuel cell inlet and vaporizer.

The VCS is a technology used at the boundary between active insulation and passive insulation and is located between the MLI end and the inner wall. Studies showed that the heat transfer in the VCS was the same as the difference in the heat exiting out and entering into the VCS. However, the heat transfer through the VCS was assumed to be sensible heat generated by the difference between the outside temperature and saturated vapor temperature.

The boil-off ratio (BOR) refers to the boil-off gas (BOG) ratio generated in a day from the entire tank. Studies demonstrated that the BOR of mobile vessels was considerably higher than that of stationary tanks owing to sloshing by vibration, which increased the stratification thickness.

Another study investigating the impact of horizontal sinusoidal sloshing on the vertical tanks demonstrated that the time-pressure curve increases when the vibration condition exceeds the critical frequency and amplitude.

Systematic Modeling

The fuel tank and fuel cell capacity are determined based on the purpose of the hydrogen vehicle. Trams, trucks, and buses typically require two to four fuel cell modules, while locomotives require one to two fuel cell modules for each of their six wheels.

The fuel efficiency can reduce with the increase in weight due to passengers and cargo. For instance, the fuel efficiency of a personal car is 90-100 km/kg, while the efficiency of a locomotive is 1-2 km/kg.

Efforts are ongoing to arrange a liquid hydrogen locomotive from a conventional diesel-electric locomotive. In the liquid hydrogen locomotive design, mass flow and engine components in the diesel locomotive will be changed to a hydrogen supply system and fuel cell, while the heating, ventilation, and air-conditioning (HVAC) system will remain unchanged.

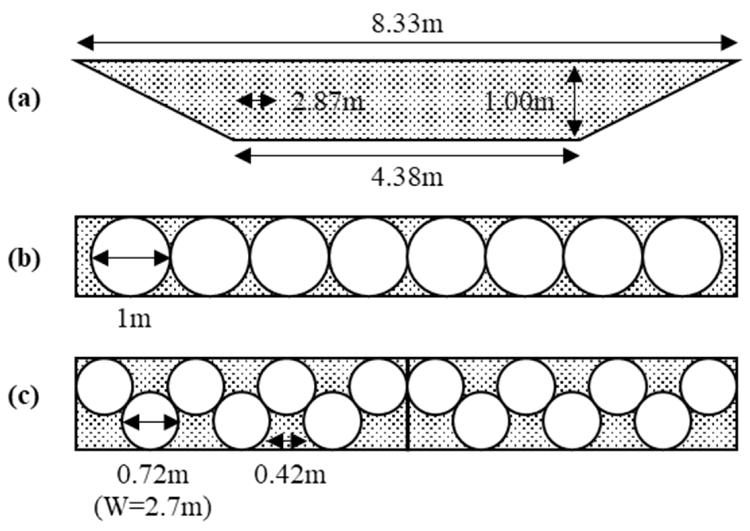

Fuel tank design: (a) size of a conventional diesel fuel tank at the bottom of the vehicle, (b) arrangement of 1-m-diameter tanks, and (c) arrangement of 0.72-m-diameter tanks. Image Credit: Kang, D.et al., Energies

However, the sizing and arrangement of the HVAC system will be changed due to the difference in the amount of heat generation by fuel cell and engine. Phase- or liquid-change cooling can be used to reduce the HVAC system volume.

The liquid hydrogen tank can be manufactured in a spherical shape and positioned inside the locomotive to maximize the thermal insulation effect, as spherical tanks have a low surface-to-volume ratio. However, a cylinder-type tank is often preferred over the sphere type due to space utilization efficiency.

The efficiency of the fuel tank can be increased by performing a thermal and structural analysis and adopting a design procedure that involves material selection. For instance, pressure control using the tank microgravity increased the fuel tank efficiency. Moreover, the change in venting based on the tank arrangement also enhanced the the system efficiency.

Conclusion

The paper reviewed the recent trends in hydrogen train research and the thermodynamic modeling of hydrogen tanks. In the future, more research is required on the optimal suspension design between baffles and vessels in the inner vessel to minimize the BOG.

Additionally, the optimal method and location of drain and filling, arrangement and materials of the insulation system and vessel wall, different liquid hydrogen vessel arrangements, locations, shapes, and the dynamic control of the mass flow, vaporizer system and pressure must be studied to improve the storage of hydrogen in different vehicles, specifically locomotives.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Kang, D., Yun, S., Kim, B.-k. Review of the Liquid Hydrogen Storage Tank and Insulation System for the High-Power Locomotive. Energies 2022. https://www.mdpi.com/1996-1073/15/12/4357