As far as researchers are concerned, producing biomaterials that can equal the performance of tendons and cartilage has been a difficult goal. However, a new material made at Cornell illustrates a hopeful new method of imitating natural tissue.

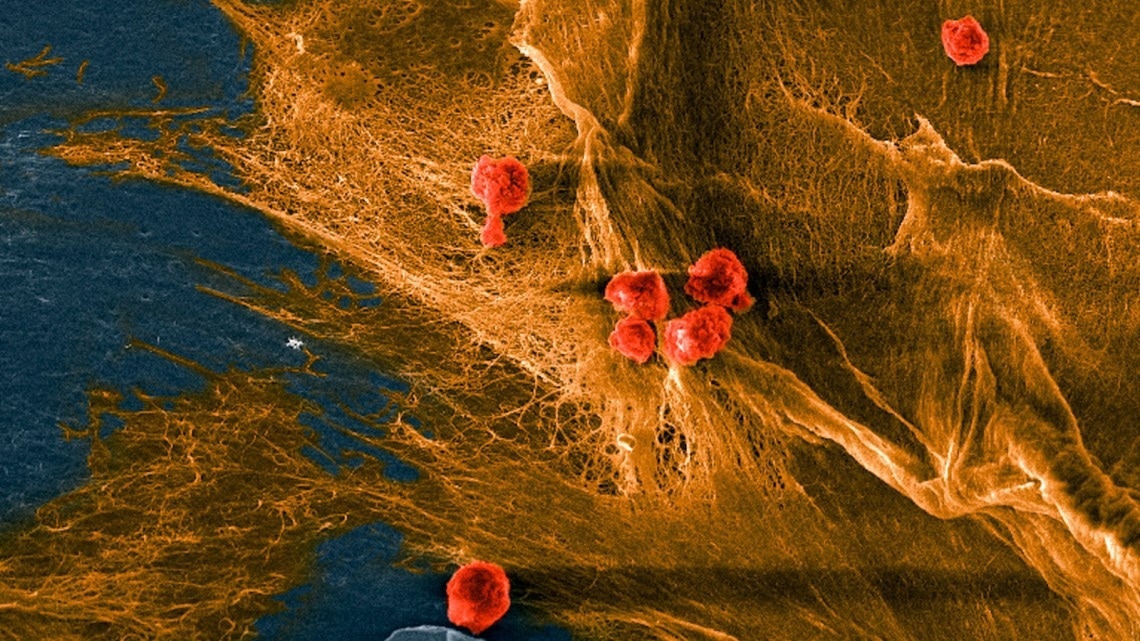

Micrograph of a biohybrid composite material developed at Cornell shows cells (red) seeded on the fibrous domains (yellow) of collagen. The material mimics natural tissue in its softness, toughness, and ability to recruit cells and keep them alive. Image Credit: Bouklas Lab/ Cornell University

Micrograph of a biohybrid composite material developed at Cornell shows cells (red) seeded on the fibrous domains (yellow) of collagen. The material mimics natural tissue in its softness, toughness, and ability to recruit cells and keep them alive. Image Credit: Bouklas Lab/ Cornell University

The outcomes were reported in the journal Proceedings of the National Academy of Sciences on July 8th, 2022, and the study offers a new plan for synthesizing clinical solutions for broken tissue.

The tissue has to be very soft to flex and bend, but strong enough to resist extended loading—for instance, the weight a knee tendon should support.

Collagen hydrogels and synthetic materials may be used to replace worn-out or damaged tissue, but neither by itself possesses the ideal blend of biological and mechanical characteristics of real tissue.

At present, Cornell scientists have designed a biohybrid composite material with the necessary characteristics of natural tissue. The material comprises two primary ingredients: collagen—which provides the material its biocompatibility and softness—and a synthetic zwitterionic hydrogel, containing negatively and positively charged molecular groups.

These charge groups interact with the negatively and positively charged groups in the collagen, and this interaction is what enables the materials to dissipate energy and achieve high levels of toughness.

Lawrence Bonassar, Study Co-Lead Author and Daljit S. and Elaine Sarkaria Professor, Biomedical Engineering, College of Engineering, Cornell University

The biohybrid composite advances the performance of articular cartilage and other biological tissues, holding around 11 times the fracture energy and 40% more elasticity—a measure of durability—of the zwitterionic material by itself.

Nikolaos Bouklas, assistant professor in the Sibley School of Mechanical and Aerospace Engineering and co-lead author of the study, stated the biocompatibility material implies it can recruit cells and maintain them alive.

Ultimately, we want to create something for regenerative medicine purposes, such as a piece of scaffold that can withstand some initial loads until the tissue fully regenerates. With this material, you could 3D print a porous scaffold with cells that could eventually create the actual tissue around the scaffold.

Lawrence Bonassar, Study Co-Lead Author and Daljit S. and Elaine Sarkaria Professor, Biomedical Engineering, College of Engineering, Cornell University

The biohybrid material is known to be self-assembling once the two ingredients are mixed, Bouklas stated, creating “the same interconnected network of collagen seen in natural cartilage, which otherwise would be extremely hard to produce.”

The study gathered four research laboratories from three various departments as a result of a seed grant from the Cornell Center for Materials Research.

The collagen that was utilized in the biohybrid composite had earlier been under development in Bonassar’s laboratory, while the zwitterionic hydrogel was advanced by the study’s co-authors Robert Shepherd, associate professor in the Sibley School, and Emmanuel Giannelis, the Walter R. Read Professor of Engineering in the Department of Materials Science and Engineering.

The authors of the study are continuing to research the material and the molecular processes behind its synthesis. Bonassar stated that the material is ideally suited for the kind of bioprinting pioneered in his laboratory, and the authors have started experimenting with utilizing it as a 3D-printing material.

Journal Reference:

Darkes-Burkey, C., et al. (2022) Simple synthesis of soft, tough, and cytocompatible biohybrid composites. Proceedings of the National Academy of Sciences. doi.org/10.1073/pnas.2116675119.