Reviewed by Mila PereraSep 19 2022

Despite their widespread use in cell phones, computers, and other devices, the complicated electrochemical surroundings of lithium-ion batteries remain unknown.

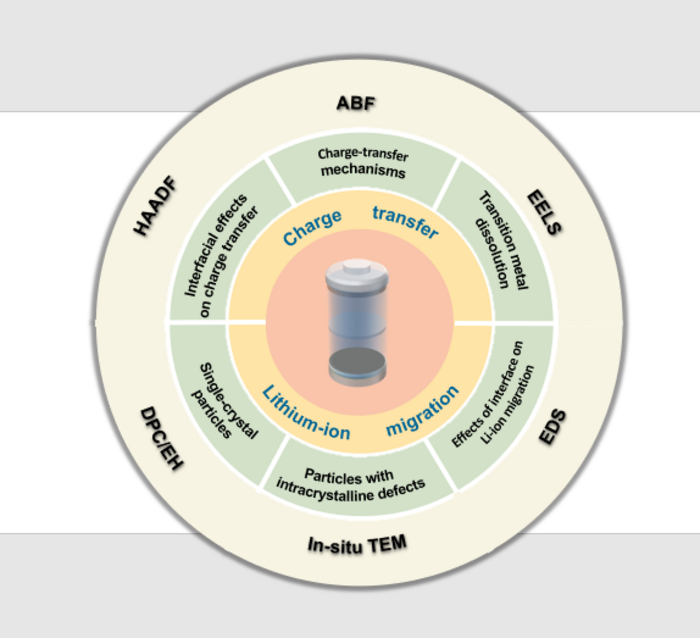

A review paper by a Tianjin University of Technology research team used various advanced electron microscopy and associate characterization techniques to clarify two structure-based mechanisms of lithium-ion batteries. Image Credit: Nano Research Energy, Tsinghua University Press

A review paper by a Tianjin University of Technology research team used various advanced electron microscopy and associate characterization techniques to clarify two structure-based mechanisms of lithium-ion batteries. Image Credit: Nano Research Energy, Tsinghua University Press

Investigators looked through the current scientific literature and used electron microscopy to investigate the charge-transfer and lithium-ion migration mechanisms that generate power to better comprehend and enhance battery performance.

On September 6th, 2022, the study was published in the Nano Research Energy journal.

Commercial lithium-ion batteries are widely used as energy storage devices, including electric vehicles, portable electronics and grid energy storage. Energy, power, charge-discharge rate, cost, cycle life, safety and environmental impact are to be considered while adopting lithium-ion batteries for a suitable application, but each specific application faces a variety of different challenges.

Yi Ding, Professor, Tianjin University of Technology

For portable electronics, the amount of energy stored is significant, whereas, for electric vehicles, cost and safety are more critical.

Cost and safety are equally essential considerations for energy grid requirements, but energy density becomes less critical than it is for electric vehicles.

The trade-off between these elements changes depending on the situation, but the capacity to tailor performance is hampered by an insufficient understanding of the materials used in batteries.

Ding says, “The active electrode materials are the main portion responsible for the cell chemistry and performance and, ultimately, affect the commercialization of the constructed battery.”

Ding continues, "The performances, such as cycle life and energy density, of existing commercial electrode material systems still need to be improved, so it is important to understand the inherent physical and chemical properties, such as structural evolution/kinetics during lithium de-embedding and the effect of electrode-electrolyte interface on the performance of lithium-ion batteries."

The researchers examined current developments in electron microscopy to evaluate how conventional characterization approaches compare to understanding the structure-activity correlations of commercial lithium-ion batteries.

By comparing with the characterization content obtained by traditional characterization techniques, such as X-ray diffraction and X-ray photoelectron spectroscopy, we illustrate the advantages and limitations of common electronic microscopes and recently developed advanced electronic microscopic characterization techniques, such as in situ electron microscopy technology, in this critical research.

Yi Ding, Professor, Tianjin University of Technology

The scientists looked at the various insights that cutting-edge electron microscopy and the related characterization methods might offer, such as how lithium ions move within the battery to build charge or how charge transfer can cause energy utilization.

They concentrated on the structure and evolution of cathode-electrode interfaces and solid electrolyte interphase during long-term cycling, the impact of the electrode structure and interface on lithium-ion migration, and transition metal dissolution and charge transfer mechanism in the charging-discharging process of lithium-ion battery positive electrodes.

Ding says that next-generation lithium-ion battery technologies are required for better cost and performance advantages, stating, “We propose the possibility of combining electron microscopy with other techniques to obtain more comprehensive information.”

Ding highlighted three common limits to electron microscopy in battery evaluation.

These include unstable temporal windows that may bias data regarding the evolution of the sample, certain batteries that cannot be quantitatively evaluated at the nanoscale, and inconsistent electrochemical environments between electron microscopy fields and actual batteries.

Ding stated, “Even with limitations, these discussions allow researchers to gain a deeper understanding of how commercial lithium-ion batteries operate at the microscale and provide guidance for design strategies for high-performance practical batteries.”

Chao Li, Bowen Liu, and co-corresponding author Ningyi Jiang, Tianjin Key Laboratory of Advanced Functional Porous Materials, Institute for New Energy Materials and Low-Carbon Technology, School of Materials Science and Engineering, Tianjin University of Technology. Jiang is also affiliated with Tianjin University’s School of Chemical Engineering and Technology and contributed to the study.

The research was financially supported by the National Key Research and Development Program of China, the National Natural Science Foundation of China, and the National Science Fund for Distinguished Young Scholars.

Journal Reference

Zhang, K., et al. (2022) Status and perspectives of key materials for PEM electrolyzer. Nano Research Energy. doi.org/10.26599/NRE.2022.9120032.