The University of Amsterdam has reached a license agreement for rapid, large-scale 3D printing with a sub-micron resolution to the Gouda-based company atum3D. The approach, created at the university’s Van 't Hoff Institute for Molecular Sciences, integrates photolithography and stereolithography to create large-scale high-resolution features.

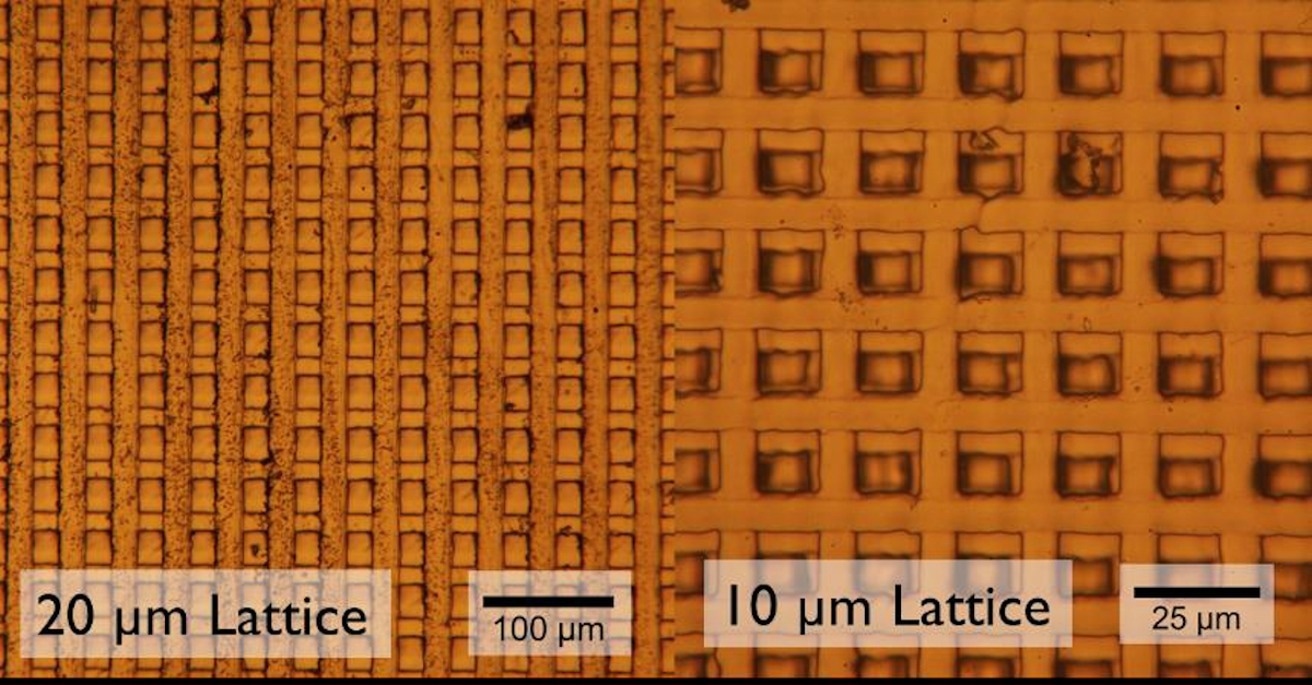

Hybrid stereolithography utilizes composite imaging where large-scale, low-resolution patterns are realized using a DLP (Digital Light Processing) projector. Within these layers, pre-defined photomasks enable the realization of micro-features. What’s more, switching photomask patterns between layers can create three-dimensional repetitive micro-features. The method can be implemented in conventional DLP 3D printers with only minor modifications. Materials include photopolymers currently used stereolithography but can also include composites such as ceramic or metal-laden photopolymers. The method has been demonstrated with a proof-of-principle setup, resulting in printed parts with feature sizes under 10 μm. The theoretical resolution limit, however, is much lower. Image Credit: Van 't Hoff Institute for Molecular Sciences (HIMS).

Hybrid stereolithography utilizes composite imaging where large-scale, low-resolution patterns are realized using a DLP (Digital Light Processing) projector. Within these layers, pre-defined photomasks enable the realization of micro-features. What’s more, switching photomask patterns between layers can create three-dimensional repetitive micro-features. The method can be implemented in conventional DLP 3D printers with only minor modifications. Materials include photopolymers currently used stereolithography but can also include composites such as ceramic or metal-laden photopolymers. The method has been demonstrated with a proof-of-principle setup, resulting in printed parts with feature sizes under 10 μm. The theoretical resolution limit, however, is much lower. Image Credit: Van 't Hoff Institute for Molecular Sciences (HIMS).

Tissue scaffolds for regenerative medicine and devices for microfluidics and chromatography are examples of potential uses.

When it comes to 3D printing of large objects, existing techniques in general offer either high resolutions or high-speed printing. The technology presently licensed to atum3D integrates the two qualities in such a way that it has applications ranging from tissue scaffolds to microfluidics and optics.

Suhas Nawada, a post-doctoral researcher at the Van 't Hoff Institute for Molecular Sciences, invented it. A patent was sought in collaboration with the university’s technology transfer agency, Amsterdam Innovation Exchange (IXA).

From Regenerative Medicine to Metamaterials and Analytical Devices

The method, termed “hybrid stereolithography,” permits high-resolution 3D printing with large sample dimensions in an acceptable amount of time. This enables the fabrication of functioning parts in high-value applications such as regenerative medicine, where organ-size parts can be printed with sub-cellular precision at a time scale appropriate for surgical procedures.

For instance, a cell scaffold was printed for a multi-centimeter blood vessel junction with pores of 50 μm, a relevant length scale for endothelial cell growth. Tristram Budel, CTO and founder of atum3D, is already exploring beyond these preliminary findings. He expects to print a full-sized heart scaffold with a regulated porous structure in less than a day.

Thanks to the scalability of the technology, building a production facility that can reliably and controllably produce organ scaffolds becomes a real possibility. But I think this definitely is an example that puts this 3D printing technology in perspective.

Tristram Budel, CTO and Founder, atum3D

A kidney might take just a quarter of the time. Budel stresses that a printed organ scaffold is still not a living organ and that much more work and research is required before an actual implanted organ can be created.

A Game-Changing Platform

A microfluidic device with 200 μm channels and 20 μm limitations is another pilot example of innovative technology. These are utilized to retain and localize chromatographic stationary phase particles, expanding the scope of 3D-printed analytical devices.

Mechanical metamaterials, semiconductors, and porous columns for reactions and separations are among the other end-use sectors. Budel anticipates a new type of additive manufacturing machine emerging.

We think that combining our current DLP technology with this new technology results in a game-changing platform. It brings possibilities that the market has never seen before: combining large decimetre scale printing with micron size features and all that in just a couple of hours.

Tristram Budel, CTO and Founder, atum3D

He added that atum3D is already developing an application and working with the new technology’s first customers. “In fact, here we come full circle as we develop this application together with the researchers at the UvA,” concludes Budel.