Reviewed by Alex SmithNov 8 2022

In the past few years, lithium-ion batteries (LIBs) have controlled the movable electronics market in a commercial manner and have slowly developed into the most hopeful market segment for electric vehicles (EVs).

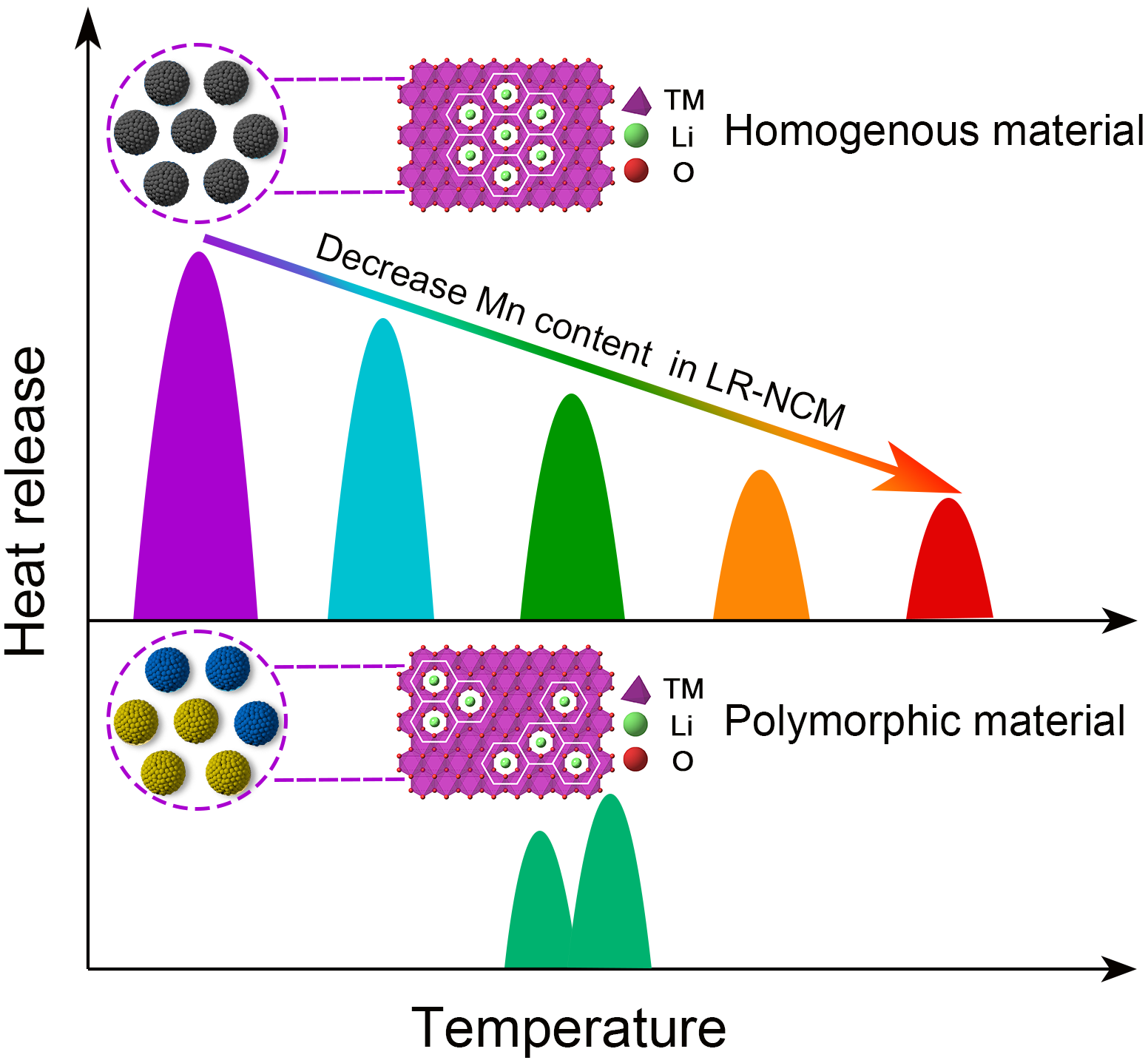

The thermally stable polymorphic layered cathode materials. Image Credit: NIMTE.

Having a discharge capacity of more than 300 mAh g-1, Li-rich Mn-based layered cathode materials have evolved as potential cathode materials for evolving high-performance Li-ion batteries.

Scientists headed by Professor Zhaoping Liu at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences have probed into the Li-rich Mn-based layered cathode materials. This provides a range of noteworthy research advances. In their study reported in Materials Today, the scientists tested the safety performance of Li-rich layered cathodes.

The outcomes display that the thermal runaway temperature of Li-rich Mn-based layered cathodes reduces with the rise of manganese (Mn) content.

Furthermore, high Mn content in Li-rich layered cathode materials contributes to a high discharge capacity but results in a thermal stability decrease and oxygen release acceleration.

Through virtue of such findings, a polymorphic composition was developed for Li-rich layered cathode material that has the potential to reach an outstanding balance between thermal stability and energy density.

Besides, the available capacity in a low Li-ion diffusion coefficient seems to be sensitive to the change of grain sizes, varying from micron-size, and submicron-size to nano-size. This was as per a study reported in the journal Energy Storage Materials.

Image Credit: asharkyu/Shutterstock.com

In comparison with the nano-sized and submicron-sized Li-rich layered cathode materials, the materials with micron-sized grains display excellent crystallinity and a greater Li-ion diffusion coefficient.

Nevertheless, the increased diffusion distance leads to an exceedingly irregular Li-ion concentration distribution at the time of the charge-discharge process. Subsequently, the strain stress within the grains accumulates, resulting in dissatisfied capacity retention and quick voltage decay.

This perception of the kinetic limitation of Li-ion diffusion in Li-rich layered oxides might help in the understanding of the alteration of Li-rich Mn-based layered cathode materials for high-performance LIBs.

Journal Reference:

Li, X., et al. (2022) Rational design of thermally stable polymorphic layered cathode materials for next generation lithium rechargeable batteries. Materials Today. doi.org/10.1016/j.mattod.2022.09.013