A team guided by researchers from the State Key Laboratory of Fluid Power and Mechatronic Systems deposited various biomaterials concurrently and accurately into the yielded region of the embedding medium with numerous individually controlled nozzles.

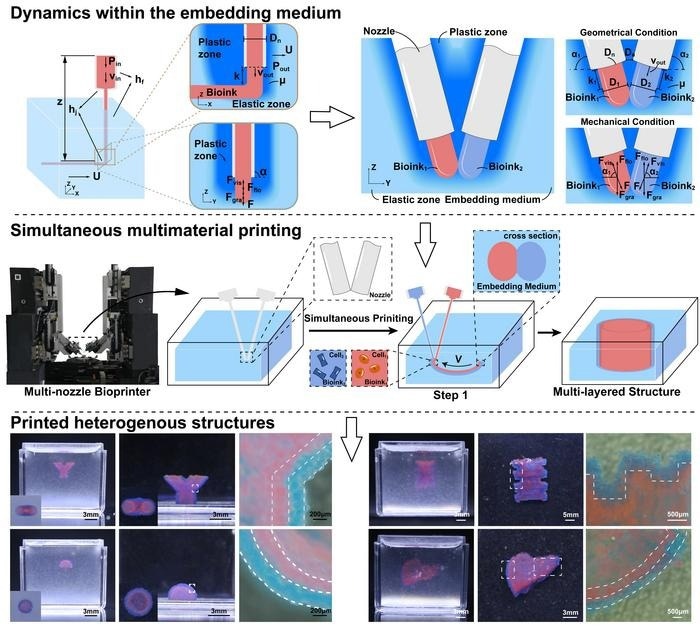

The process and results of simultaneous printing. Image Credit: Ziqi Gao, Jun Yin, Peng Liu, Qi Li, Runan Zhang, Huayong Yang and Hongzhao Zhou

The study was published in the International Journal of Extreme Manufacturing.

In comparison to the standard sequential printing approach, the new printing method could control the correct deposition of bioink to assure position fidelity and structure morphology, as well as improve layer bonding strength. The discovery has the potential to be widely utilized in the fabrication of heterogeneous structures using soft biomaterials and soft composites.

Multi-material bioprinting technology provides different choices of cells and biomaterials for the in vitro construction of heterogeneous structures that may be a better representation of natural tissues/organs. Embedded printing technology provides more possibilities for printing various materials to complex three-dimensional structures.

Hongzhao Zhou, Lead Researcher and Associate Professor, State Key Laboratory of Fluid Power and Mechatronic Systems, Zhejiang University

However, the embedding medium has a viscosity larger than air, which would have a stronger impact on the continuous position of the extruded bioink. The bioink is placed in the embedding medium and kept almost completely in place. There is no certainty that adjacent filaments will adhere. Because of the possibility of developing in vitro tissues with diverse materials, it is essential to accurately regulate the deposition of ink in the embedding medium to form heterogeneous tissues.

A simple and widely used method in traditional embedded printing is to design adjacent filaments spatially overlapped such that they can be joined with each other.

The overlapping method has been proven effective when printing continuous structures with a single material. For complex structures with multiple materials, the overlapping of filaments may induce the uncontrolled stacking and squeezing of the adjacent filaments and jeopardize the spatial distribution of different materials in the printed structure.

Dr. Ziqi Gao, Study First Author, State Key Laboratory of Fluid Power and Mechatronic Systems, Zhejiang University

Dr. Ziqi Gao adds, “In our work, we analyze the dynamics of the extruded bioink in the embedding medium. We evenly mix fluorescent microspheres into the ink to determine the contour of the printed filaments and print the filaments simultaneously in the embedding medium with different printing parameters. We can compare and verify the experimental phenomena with the results of key parameter changes in theoretical analysis. This novel printing method can achieve horizontal connection between fine threads under a wide range of printing parameters.”

Through the above experimental methods, the effects of printing parameters including printing speed, rheology of embedding medium on the 3D morphology of the printed filament are quantitatively evaluated. Under the conditions of high printing speed and low viscosity embedding medium, simultaneously printed filaments exhibit high accuracy and aspect ratio close to 1, which can adapt to the slice trajectory and enable us to manufacture micro structures.

Jun Yin, Study Co-First Author and Professor, State Key Laboratory of Fluid Power and Mechatronic Systems, Zhejiang University

“Double-layer thin-walled structure with each layer less than 200 μm was printed. It was demonstrated that intestine and liver models could be printed. The intestine showed a structure similar to the circular fold shape of the real organ. Both the tissues can be crosslinked and extracted from the embedding medium without significant impairment or delamination,” noted Jun Yin.

Jun Yin adds, “Also, a peeling test was carried out to investigate the bonding strength between simultaneous printed specimen, results were compared with the casted and sequential printed specimen. We found that the bonding strength of the samples by simultaneous printing was significantly greater than that of the samples by sequential printing under the same trajectory. The proposed simultaneous printing method has minimized the chance of the contamination of the embedding medium for the 3D printing of multi-layered and multi-material structures. And it could be a direct solution of the present structural integrity problems for such structures.”

The researchers investigated a multi-material embedded printing method that has the potential to fabricate heterogeneous structures with excellent precision and structural integrity. This technology could be utilized to create in vitro tissue models using soft biomaterials and soft composites.

Journal Reference

Gao, Z., et al. (2023). Simultaneous Multi-material Embedded Printing for 3D Heterogenous Structures. International Journal of Extreme Manufacturing. doi.org/10.1088/2631-7990/acd285.