Archer Materials Limited (“Archer”, the “Company”), a semiconductor company that advances the quantum computing and medical diagnostics industries, has achieved a significant development milestone in the functionality of its cutting-edge qubit material.

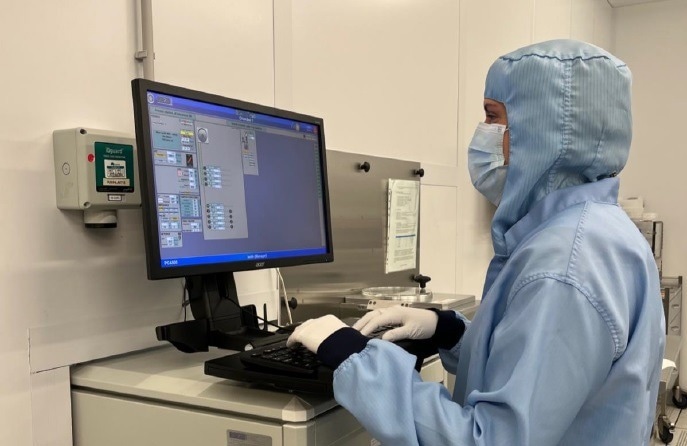

Image 1. Archer staff in a research and prototyping semiconductor foundry in Sydney, Australia, operating some of the instruments used to encapsulate the qubit material. Image Credit: Archer Materials Limited

Image 1. Archer staff in a research and prototyping semiconductor foundry in Sydney, Australia, operating some of the instruments used to encapsulate the qubit material. Image Credit: Archer Materials Limited

The Company recently optimised the room-temperature functionality of its qubit material (ASX ann. 8 Jun, 2023). Until now, there was a need for a vacuum or inert atmosphere when operating the qubit material to preserve viable quantum coherence times. To advance the Company’s 12CQ chip development, there is a requirement for simple and practical solutions to address quantum decoherence caused by air on the qubit material.

The Archer team has now for the first time preserved the qubit materials’ quantum coherence times and properties at room temperature in air while maintaining the intrinsic metallic-like character of the qubit material. Importantly, the quantum coherence times meet the lower-bound requirements to perform gate operations for quantum information processing. In the context of qubit processor development, applying foundry-compatible processes to readily handle and process a qubit material while preserving quantum coherence is significant.

The Archer team was able to achieve this pivotal development by applying methods of atomic layer deposition (“ALD”) and also plasma enhanced chemical vapour deposition (“PECVD”), to encapsulate the qubit material with atom-layer control over nanometre and micrometre thin films of metal oxides and other semiconductors.

Commenting on the newly developed nanomaterials technology, Dr Mohammad Choucair, CEO of Archer, said,

“This is a major achievement for Archer’s qubit development. It shows the strength of Archer’s strategy to be an enabler for the sector, with our innovations making qubit materials potentially more accessible and more easily embedded in modern day semiconductor fabrication processes for quantum logic device manufacture”.

“Archer has now demonstrated its qubit materials’ quantum coherence times observed at room temperature can be achieved under normal conditions, in air. This means the approach has the potential for technology translation to industrially scale Archer’s 12CQ qubit chip architecture.

“It is remarkable that Archer’s carbon qubit material is so readily produced yet remains robust post-processing to generate the fragile quantum states for the long enough periods of time needed for quantum logic operations in the qubit devices we are developing.

“Archer continues to move closer to making quantum processing devices in a much more easily-produced reality in everyday electronics with this latest milestone.”

Background

Quantum coherence is the fundamental requirement for quantum logic operations that are the basis of any quantum computing qubit processor hardware. For potential integration and use of qubit materials in practical chip devices, it is significant to demonstrate and validate robustness at room temperature and under atmospheric environments.

Earlier this year, Archer announced that it was working towards a potential breakthrough in the semiconductor foundry packaging of the 12CQ chip architecture (ASX ann. Mar 16, 2023). As part of that work, Archer’s nanodevice engineers have been progressing the development of a method to encapsulate its qubit material. The encapsulation approach involves coating the qubit material with a nanometre-thin passivation layer, mimicking an ‘artificial vacuum’. The primary purpose of the encapsulation is to allow the qubit material to function under ambient conditions3. The work used common semiconductor foundry cleanroom processing methods.

This milestone links to the future operation and fabrication processing of Archer’s 12CQ chip and builds on previous work focused on qubit materials’ and device fabrication optimisation (ASX ann. 14 Oct, 2021 and 8 Jun, 2023).