Researchers say they've developed a method that could replace the two diesel engines currently powering a ferry boat with pneumatic propellers—offering a potentially cleaner, quieter, and more efficient alternative for short-distance maritime travel.

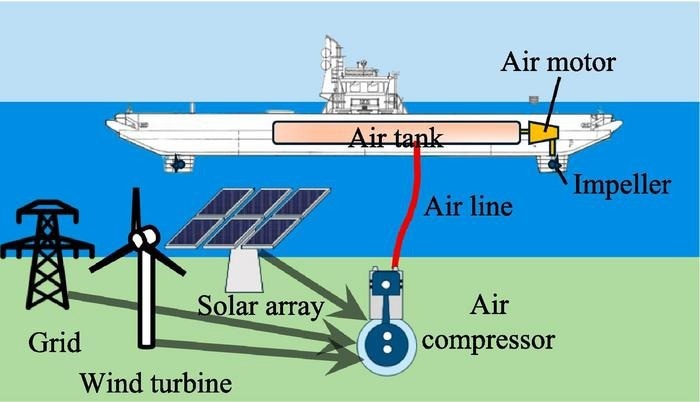

Schematic of the proposed pneumatic propulsion with multi-option for connectivity, be it grid and/or renewable energy connectivity. Image Credit: Energy Conversion and Management

According to the team, the two air motors used in place of the diesel engines each generated 250 kW of power, enough to keep the ferry operating reliably on a set route within Finland’s maritime transport system.

Published in the journal Energy Conversion and Management, the study aimed to assess both the technical and economic feasibility of replacing conventional diesel engines with pneumatic propulsion on an existing vessel.

The research was, “conducted to evaluate the technical and economic feasibility of replacing the conventional diesel engine with a pneumatically propelled one on an existing ferry boat within the context of Finland's maritime transport needs. It is demonstrated that pneumatic propulsion, while unconventional, holds a promise as a sustainable and energy-efficient alternative to conventional marine engines, particularly for short-distance ferry operations,” the scientists noted.

While diesel engines are still valued for their power density and durability, they rely heavily on fuel, generate significant noise, and are major contributors to air pollution.

Replacing these engines with pneumatic ones is a cleaner and more effective option as these engines can also be incorporated into the ferry body to store air either within the structure of the boat or on auxiliary tanks, which will enhance buoyancy.

Abdul Hai Alami, Study Lead Author and Professor, Sustainable and Renewable Energy, University of Sharjah

The research draws on both experimental results and realistic modeling, using polytropic relations to analyze how compressed air behaves from storage to flow into the air motor that powers the propeller.

Using this method for maritime vessels is attractive from economic, practical, and environmental vantage points and could be easily adapted to most ferry boats even in harsh conditions.

Abdul Hai Alami, Study Lead Author and Professor, Sustainable and Renewable Energy, University of Sharjah

Pneumatic propellers rely on compressed air to drive motors or mechanical systems, rather than using diesel, electricity, or battery power. The propulsion method involves high-pressure air tanks that feed a vaned air motor, which is then linked to a naval impeller.

The authors describe their work as “a techno-environmental study... with a life-cycle assessment” aimed at replacing diesel engines with pneumatic propulsion on an operational ferry.

“The proposed system has lower operational cost and an attractive payback period. The proposed system is reliable with significantly smaller environmental impact in context,” they wrote.

What makes the study particularly notable is that the researchers applied their concept to a real-world scenario—a ferry built in 1985 and still powered by diesel engines.

Co-author Kaj Jansson, a Finnish ferry maker with K.J. Marineconsulting Ab, supervised the engine swap and the ferry’s test runs using its new pneumatic propulsion system.

Pneumatic propulsion is the future of sailing on fixed maritime routes. The predictability of pace, payload, and destination of ferry boats allows replacing conventional diesel engines that are efficient and reliable but are polluting, noisy, and sensitive to fluctuating oil prices with pneumatic ones.

Kaj Jansson, Study Co-Author, Finnish K. J Marineconsulting Ab

The authors noted, “From a technical perspective, the proposed pneumatic system exhibited satisfactory performance, meeting the same propulsion requirements as the diesel engine system. The modular design of pneumatic systems offers scalability and adaptability to varying operational needs, aligning with the growing demand for flexible and environmentally conscious transport solutions.”

Further said, “Economically, the proposed pneumatic system offers competitive advantages in terms of reduced fuel costs and lower maintenance requirements due to its simplified mechanical design. When analyzed from a lifecycle perspective, the pneumatic ferry presented a feasible option for cost reduction in comparison to diesel-powered counterparts. A staggering cost saving of USD 73,000 is calculated with a payback period of 8 years.”

Prof. Alami said he remains hopeful that the method will gain traction within the maritime sector.

“The research and development in vaned air motors will allow using more advanced materials, resulting in stronger pneumatic engines. The research has concluded that the payback period of retrofitting the ferry with air motors instead of diesel engines to be around 8 years. This is a very conservative claim as the best-case scenario was not applied all the time when making assumptions,” Professor Alami concluded.

Journal Reference:

Alami, A. H., et al. (2025) A techno-economic-environmental investigation of replacing diesel engines with pneumatic motors for ferry boats. Energy Conversion and Management. doi.org/10.1016/j.enconman.2025.119613.