HP DSC is widely used in many different industries such as the chemical, pharmaceutical, petrochemical, plastics, paints and adhesives, electronics, and food industries and in academia.

Why use HP DSC?

Increased pressure influences all physical changes and chemical reactions in which a change in volume occurs. This means that increased pressure has a direct effect on many processes and reactions.

The most important reasons for using HPDSC are:

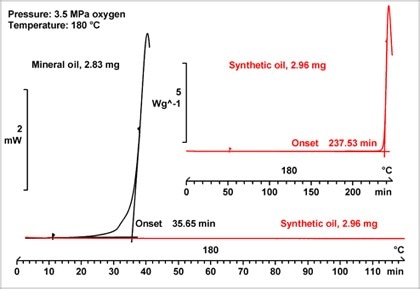

- Higher pressures and temperatures accelerate the rate of chemical reactions and result in shorter analysis times.

- HPDSC allows practical reaction environments to be simulated so that measurements can be performed under real process conditions.

- Finally, higher pressure suppresses vaporization. Overlapping effects in DSC curves can be better separated because the effect due to vaporization is shifted to higher temperature. This simplifies DSC curves and makes them easier to interpret.

HP DSC Options

A METTLER TOLEDO HP DSC can be fitted with two important optional accessories for specific applications:

The HP DSC 1 Microscopy system allows you to observe a sample visually while it is heated or cooled in the DSC. Valuable information can be obtained about changes due to relaxation, melting, solid-solid transitions, the shrinkage of fibers and films, or reaction processes.

The HP DSC 1 Chemiluminescence system simultaneously detects the light emission and the heat flow from a sample subjected to a precisely controlled gas pressure at a particular temperature. Chemiluminescence measurements of materials provide information about local oxidation rates and the influence of stabilizers in different materials.