Image Credits: Funtay/shutterstock.com

Dynamic mechanical analysis (DMA) is an analytical characterization technique that is used to study the physical properties of a range of materials in different temperature environments. One example where it has found a lot of use is in measuring the viscoelasticity of polymers. It is a technique that has been around commercially since the 1950s and has found use across a lot of industries for measuring the properties of materials.

While they have been around since the '50s, most of their use has come since the 1980’s when they were paired with computers of ample processing power that could better analyze the materials. It started as a relatively basic technique that could only measure the physical properties of solids, but modern-day machines can now analyze materials in arrange of forms, from solids to liquids and pastes.

Oscillating Stress

In dynamic mechanical analysis, a stress/strain force is applied in an oscillatory motion to the material under analysis, and this applied force is used to calculate the stress or strain (i.e. the deformation) that the material itself is experiencing. This enables the user to determine the different properties of the material depending on how they behave under certain stress environments over time and at certain temperatures (as different temperatures can also be applied). The application of oscillating stress compared to linear stress is that it enables the properties of deformation and reformation to be analyzed, rather than the stress limits under an applied load.

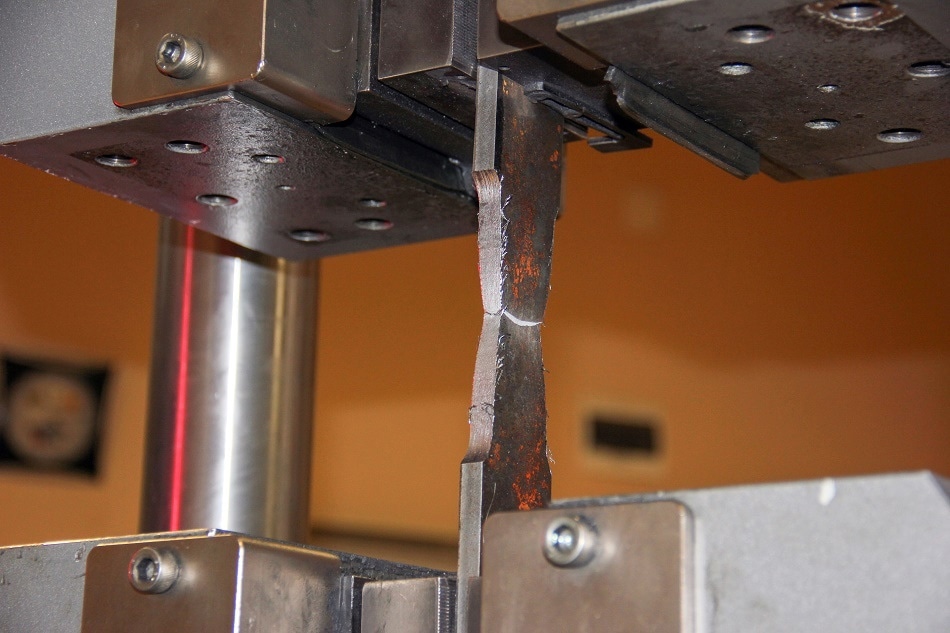

When the oscillating stress is applied, the modulus is subsequently calculated using the elastic response of the material when it is in-phase of the applied stress. The damping of the material is then calculated by measuring the response of the material when it is out-of-phase to the applied stress. To do this, the material is held between clamps while the stress is applied. The stress is often applied to the material using an electric motor, where the electric motor operates in either a rotational (back and forth) or linear (up and down) motion. The frequency, i.e. the oscillating speed, and the force are then applied using predetermined values depending on the material being analyzed and the properties which are being investigated. To maintain the ideal temperature/to analyze the physical properties in a certain temperature range, the analysis takes place in a furnace, which keeps the temperature constant during the analysis.

Dynamic Mechanical Analysis Modes

There are a number of different mechanical forces that can be applied to the material being analyzed, and these are often referred to as the different DMA modes. The different forces, i.e. modes, that are common in DMA analyses are tension and compression (sinusoidal force), shear, dual cantilever bending, and 3-point bending modes. There is no standard mode, and the choice of mode used is dependent on the shape of the sample, the modulus and the reason for the analysis, i.e. the types of measurements being taken.

The strain and/or stress exhibited by the material itself under the applied strain is then measured. The measurement is often taken using a linear variable differential transformer (LVDT) or a force transducer, and the resulting data is often outputted in a graph—where the values plotted are the storage modulus, the tan delta (which is the damping) and the temperature. For measuring the temperature during the analysis, a thermocouple is typically used.

Even though dynamic mechanical analysis is a technique that is widely used to determine the direct physical properties of a material (such as the viscoelasticity or stiffness of a material), it is a technique that can also be used to determine the phase behavior of a material. In the area of phase behavior, DMA can be used to measure the glass transition temperature of a material, if any secondary transitions occur, the orientation that a material adopts during processing, how the filler molecules affect the physical properties of a composite, as well as the cold crystallization and cure optimization properties of a material. In addition to the fundamental properties of a material, DMA can also be used to see how the applied load directly affects the stability of the material and can be used to see if a material exhibits any creep and stress relaxation under applied stress.

Conclusion

Dynamic mechanical analysis is a technique that is not always the most accurate for deducing the mechanical properties as a stand-alone technique, but it is a type of thermal and mechanical analysis technique that is often used in conjunction with other techniques to build up a complete picture of a material’s properties/behavior in certain environments.

Sources and Further Reading

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.