| Although world steel production has grown at a relatively slow rate since the mid 1970s, the process by which the steel is produced has changed, with a continuing shift from open hearth to oxygen steelmaking and more recently an increasing emphasis on EAF production, figure 1. The timescale for the deployment of such new process technology is measured in decades owing to slow growth, long life of existing plant and the low variable cost of current blast furnace and basic oxygen steelmaking (BOS) plant. The cost factor is crucial, as it is not economically viable to replace existing BF/BOS plant with new technologies such as electric arc furnaces, direct reduction or smelting reduction until the plant reaches the end of its life. |

| | Figure 1. The processes used for worldwide processing steel for the period 1950-1996. | As a result, the strategy in areas where there is little or no growth is to maximise the profitability and competitiveness of existing plants, prior to replacing them at the end of their life in a cost effective way. In areas where there are growth opportunities, there is a wide range of process technologies that can be tailored to match local market demand, feedstock and energy availability. This article gives examples from within British Steel of developments to increase the competitiveness of existing plants and summarises the new process technologies available. Improving Profitability British Steel seeks improvements to profitability through cost reductions, extending plant life, higher quality and higher value products. The company has made cost reductions in the area of ironmaking through advances in blast furnace performance. Productivity has increased thanks to operational improvements and also by reducing the number of furnaces, removing the older, most inefficient units. Equivalent coke rate in the furnace has reduced from 540 kg.thm-1 in 1980 to 480 kg.thm-1 in 1997. In addition, coal injection has increased and now is installed on most furnaces in British Steel. Developments in other fuel injection technologies, such as oil and natural gas, have also continued, and the use of fuel injection will increase. Consequently, coke consumption will continue to fall, minimising imports. Extending Plant Life Maximising asset life to defer expenditure on plant replacement is also key to maintaining competitive plants. Cokemaking developments in the areas of coal blend selection, control and monitoring, improved maintenance and inspection are geared to achieving a 40 year campaign life on current coke oven batteries. Blast furnace productivity has, over the past six years or so, levelled off and in recent times decreased. This is owing to the emphasis being placed on extending plant life as much as possible. As an example, Redcar blast furnace has reduced its daily production capacity from more than 10 ktpd to 9.2 ktpd. Key developments in ironmaking on life extension include: • operator guidance systems for improved operation and reduced fuel rates • liquid management systems using EMI's • plant condition monitoring • a stability task team • a long life hearth group • shell cooling improvements. Control Systems Blast furnace stability and control are important for maximising plant life. There have been developments in instrumentation, probes, expert systems and process control. Systems are now available that supply the operator with advance warning of furnace instability. Several key process variables are monitored and correlated, such as off-take temperatures, bosh and stack differential pressure, Eta CO and stock rod monitoring. Higher Quality Steels For producing higher value added products, higher quality steel must be produced in the first place. Over the past two decades, quality improvements have been developing, particularly with the introduction of secondary steelmaking. With the recent improvements in computing power and information technology, several examples of secondary steelmaking process control developments can be highlighted. These include ladle thermal tracking, ladle additions modelling, ladle power input modelling and process route timing. Other process and engineering developments include the smart lance, sub lance, tank degasser and a reduction in slag carryover. These have all led to substantial improvements in steel grade quality that can now be produced. Improved Casting Technology British Steel has invested substantially in casting technology, with many projects for either new casters or caster enhancements since 1994. Retrofitting new technology into existing plant is a key means of enhancing performance and the installation of a heat removal device to achieve near liquidous casting is an example of this. This process development has provided better quality in terms of improved segregation ratios. Higher Value Added Products Partly owing to improved steel quality being available and partly owing to process and engineering developments, the capability to produce higher value added products has increased. Current examples within British Steel are Slimdek (based on the asymmetric beam), the jumbo column, Bisteel and Lasersure. Indeed, Slimdek has been chosen by the Design Council as one of only six construction related products to be nominated as a ‘millennium product’. This scheme was proposed to identify and encourage the UK’s most innovative products and services. Finite Element Analysis

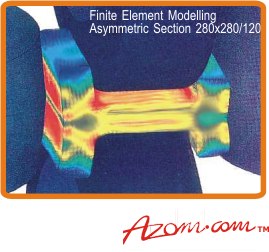

Important to rolling development is finite element analysis, figure 2. This enables accurate simulations of the rolling process to optimise shape development through the process within the capability of the mill. This can lead to faster development and lower development costs of new products, the ability to optimise product quality, improved process understanding and input into design of new rolling equipment. Future development in this area includes metallurgical modelling to predict product properties. |

| | Figure 2. Finite element analysis for the accurate simulation of rolling processes. In this instance for an asymmetric section. | New Process Technologies New process technologies are being developed, with the aim of achieving: • lower capital costs • economic viability at small scale • lower operating costs • raw material flexibility • environmental benefits. The main areas for new process technology are alternative ironmaking, EAF steelmaking and casting technologies. Alternative ironmaking can be split into two parts: • direct reduction (scrap substitute) • smelting reduction (hot metal replacement). World direct reduced iron (DRI) production has increased markedly in the past 6 years, as the product is predominantly used in the EAF and therefore demand has increased with increasing global EAT steelmaking. Current world DRI production stands at 36 Mtpa (figure 3). |

| | Figure 3. World direct reduction iron (DRI) production by process. | There are several DRI processes but the Midrex process is by far the most prevalent. Newer fines based processes are being built, such as Finmet and Circored, and these should provide even lower operating costs. The only commercially available smelting reduction process currently available is Corex, with two operating plants worldwide and three other projects under development. Corex uses agglomerated ores as the feedstock and currently has a maximum capacity for a C3000 unit of 1.08 Mtpa. The next generation of fines-based smelting reduction processes are still several years away from fully being developed and include Hismelt, CCF and DIOS. Electric Arc Furnaces Electric arc furnaces have comparatively low capital costs at a capacity of 1 Mtpa, when compared to conventional ironmaking. The viability at small scale and the ability to feed regional markets with product from greenfield site developments has led to this technology being the first choice for new growth. To make the process even more attractive there are ongoing improvements to the EAF design concept, such as twin DC electrodes, oxy-fuel energy, scrap preheat, high furnace aspect ratio, twin shell and DC furnace. Casting Developments Casting developments have aimed to reduce the number of process steps involved in producing the final product. Conventional casting machines may be up to 800m in length, containing repeating furnace, roughers and finishers. With the advent of thin slab casting the number of stages is reduced, typically reducing machine length to 250m. Figure 6 shows a thin slab caster, commercialised in 1989, with more than 30 installations to date, including British Steel's investment in two US-based mills, Tuscaloosa and Trico. |

| | Figure 4. Schematic of the thin slab casting process, aimed at reducing machine length. | Another development in casting is direct strip casting at much thinner gauges. Worldwide there are 15 developments underway, mainly for stainless product, with an NSC plant scheduled to be commence operation later this year. Summary When investing in plant in growth areas, there are many different process combinations available and these must be tailored to meet local needs with respect to market demand, product mix and quality, and feedstock and energy. Options available include the BF/BOS route for high growth areas, EAF developments for smaller regional markets with good scrap and electricity availability and smelting reduction processes for areas with cheap coal. When replacing end-of-life plant, the options are similar, plus rebuilding existing assets. In summary, the strategy in areas where there is little or no growth is to maximise the profitability and competitiveness of existing plants, prior to replacing them at the end of their life in a cost effective way. In areas where there are growth opportunities there is a wide range of process technologies available, which can be tailored to match local market demand, feedstock and energy availability. |