The OmniScan® X3 flaw detector offered by Evident/Olympus is a comprehensive phased array toolbox. Robust tools, such as advanced visualization capabilities and total focusing method (TFM) images, allow users to complete their inspection with more confidence.

Innovative TFM

- Early-stage high-temperature hydrogen attack (HTHA) can be imaged to identify it when it matters most

- Improved flaw imaging brings resolution and clarity to smaller defects

- Up to four TFM modes allow interpretation and sizing of flaws

- Onboard acoustic influence map (AIM) reflectivity simulator allows users to visualize the sensitivity of TFM and adjust accordingly

Improved Phased Array

- Enhanced fast-phased array calibration reduces frustration

- Single TOFD menu expedites workflow

- Onboard Dual Linear Array™, as well as Dual Matrix Array™ probe support, enables faster setup

- A high amplitude range of 800% decreases the need to rescan

- Twice as fast as the OmniScan MX2 phased array flaw detector (pulse repetition frequency)

Image Credit: Evident Corporation

Users Can Get to Work, Quickly

The streamlined user interface, improved and rapid calibration, and the onboard scan plan help eliminate the unwanted steps. These features allow users to complete their inspection setup in a short period of time.

If customers are existing OmniScan users, they can quickly switch from the OmniScan MX2. However, if customers are new to TFM or phased array ultrasonic testing, they can easily learn the OmniScan X3 flaw detector.

Reliability that can be Trusted by Users

- Users can download the latest software by connecting wirelessly to the Evident Corporation Cloud™

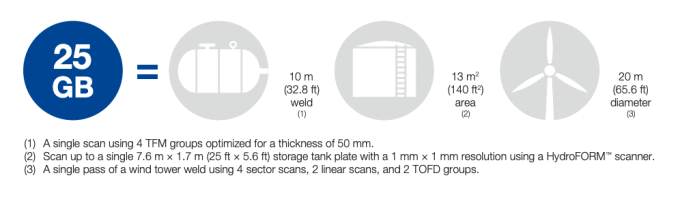

- Thanks to the 25 GB file size, users can scan continuously

- Onboard GPS offers data location

- IP65 certified rain and dust proof

Image Credit: Evident Corporation

Image Credit: Evident Corporation

The Workhorse of Inspection Fleet

Evident’ OmniScan X3 flaw detector has the required tools to help users to complete their job in an efficient way. Its application range includes pipes, pipelines, welds, corrosion mapping, corrosion-resistant alloys, composite inspection, HTHA inspection, flaw imaging, and detection of stepwise cracking.

- The 32:128PR model features 64-element TFM

- Models 16:128PR and 16:64PR are also available

- Can be used with current scanners and probes

- 64 GB internal storage, extendable with an external USB drive

- Adaptable with MX2/SX files for users’ convenience

- A maximum of eight groups, 1024 focal laws

OmniScan X3 64 Flaw Detector

The OmniScan X3 64 flaw detector from Olympus has been housed in the field-proven rough and portable OmniScan X3 enclosure. Hence it provides strong focusing abilities aided by its bigger element-aperture capacity allowing users to completely exploit 128-element aperture TFM and 64-element phased array probes.

The detector makes use of its improved performance to fulfill the inspection challenges of thick and attenuative materials and extend users’ potential to come up with new procedures for an extensive range of applications.

Keep Pace with Production

Users can ask Olympus representatives about the limited-time OmniScan X3 64 launch promotion, which includes a WeldSight software inspection license.

OmniScan™ X3 Phased Array Flaw Detector with Innovative TFM

Confidence Users Can See

The OmniScan X3 flaw detector is a full phased array toolbox. Strong tools, such as total focusing method (TFM) imaging and sophisticated visualization capabilities, which have been backed by its high image quality, allow users to finish inspection with confidence.

Innovative and Efficient TFM

Confirm Users TFM Beam Coverage in Advance

The Acoustic Influence Map (AIM) tool offers users an instant visual model of the sensitivity based on their TFM mode, settings, probe, and simulated reflector.

The AIM tool takes the guesswork out of establishing a scan plan — users can envision the effect of a wave set (TFM mode), note where sensitivity stops, and adjust the scan plan accordingly.

Up to Four TFM Modes Facilitate Flaw Interpretation and Sizing

Making use of various TFM modes (wave sets) in the same inspection increases users’ chances of detecting oriented indications in an irregular manner. The OmniScan X3 flaw detector offers up to four concurrent TFM modes to produce images from different angles.

The response and characteristics obtained from each mode — like the tip diffraction, defect profile, and corner trap — could be utilized concurrently to verify the flaw type and enhance the sizing abilities.

Virtual Collaboration, Virtually Anywhere

The X3 Remote Collaboration Service (X3 RCS) allows users to share their screens, enable a remote collaborator to control the unit, and host a video conference with participants situated in almost any place in the world.

Improved, Faster Calibration

The OmniScan X3 calibrator helps track the signals at high speed. It is possible to execute multigroup calibrations in just minutes.

Familiar Yet Improved OmniScan Experience

Users who own or are trained on an OmniScan will transition in a simple way to the OmniScan X3 flaw detector, and it will be very easy for the new users to learn.

Benefit from 64-Pulser Phased Array

Users can exploit the complete potential of 64-element phased array probes with the help of the OmniScan X3 64 flaw detector to achieve enhanced resolution at the focal point.

Image Credit: Evident Corporation

Access Full 128-Element Aperture TFM

TFM imaging has been made possible by new generation electronics, and it hence provides improved focusing abilities for smaller indications and an enhanced signal-to-noise ratio (SNR). With the help of its 128-element aperture capacity, the OmniScan X3 64 model offers improved image clarity.

Image Credit: Evident Corporation

Acquire up to 4X Faster TFM

Users can obtain total focusing method (TFM) acquisition speeds ranging up to 4 times faster while making use of a 64-element probe. In comparison to models with 32 pulsers, the OmniScan X3 64 flaw detector provides a considerable enhancement in efficiency as a result of its bigger aperture capability.

Improved Phased Array

- Speed is up to 3× as fast as the OmniScan MX2 flaw detector (max pulse repetition frequency)

- 800% high amplitude range decreases the need to rescan

- Onboard Dual Linear Array™ and Dual Matrix Array™ probe support expedites setup creation

- Single TOFD menu available for an expedited calibration workflow

Ease Corrosion Monitoring Using Phased Array

Using a phased array to inspect corrosion provides numerous advantages, such as outstanding coverage and resolution. But becoming proficient in phased array methods could be difficult.

The OmniScan X3 flaw detector integrates sophisticated functions like gate synchronization with carefully designed software and simplified menus. This helps users to achieve precise data in a simpler manner. Users can configure their setup quickly as a result of its A-scan synchronization processing and manual time-corrected gain (TCG).

OmniScan® X3 Phased Array Flaw Detector Overview