Pipe elbows are prone to damage, such as from flow-accelerated corrosion (FAC). However, pipe elbows are difficult to inspect because their shape varies from convex to concave, and there are many different pipe diameters.

Evident’ FlexoFORM solution combines flexible phased array probe technology with a scanner to overcome these difficulties. When used with a water column, the solution can acquire easy-to-interpret data on elbows with diameters spanning from 4.5 in. (114.3 mm) OD up to flat.

It provides many other advantages, such as:

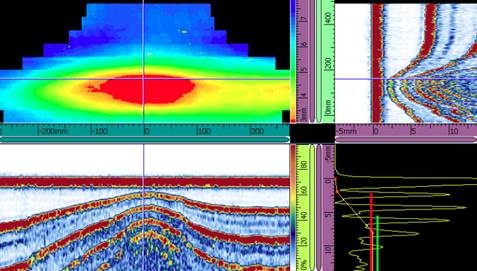

- Intuitive 2D C-scan imaging

- Rapid measurement of elbow wall thickness

- Complete elbow coverage

- High-resolution data (1 mm × 1 mm)

Image Credit: Evident Corporation

High-Resolution Data

When used with an OmniScan™ MX2 or SX instrument, the scanner identifies and measures different types of anomalies or damages like corrosion pitting, remaining wall thickness, and mid-wall inclusions or lamination.

High-density data combined with the numerous views available on the OmniPC™ software or flaw detector offers clear images of the elbow’s condition and enables fast and easy data interpretation. The scan direction is encoded, while an indexing button is directly located on the scanner to carry out index increments in the second axis.

The scanner is securely fixed to the pipe through magnetic wheels, and a foam gasket permanently remains in contact with the surface to ensure the water column is filled.

A water wedge reduces water consumption and enables easy control of air bubbles. It also enables the scanner to conform to concave and convex elbow shapes, couple to surfaces that have moderate roughness, and synchronize data to the front wall.

Each wedge is designed to fit a specific pipe diameter. Operators can easily mount the probe and wedge assembly on the scanner, and the system is ready to use.

Image Credit: Evident Corporation

FlexoFORM™ Scanner for Pipe Elbow Inspection Overview