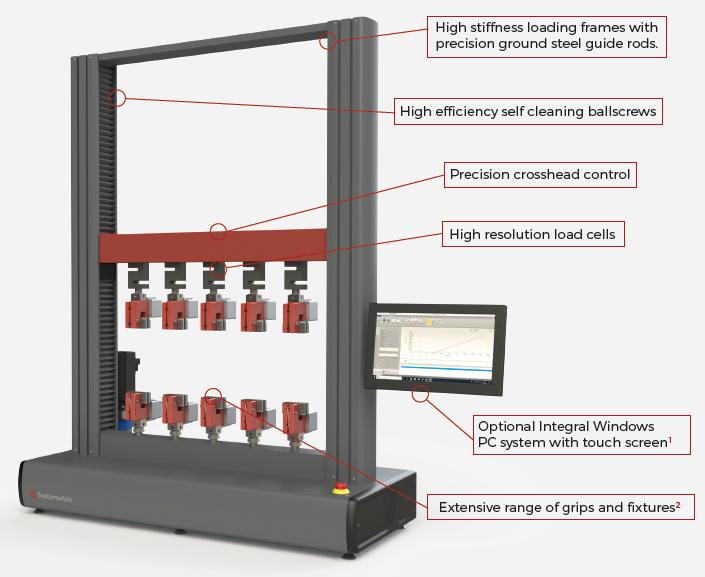

The multi-station version of X500 models from Testometric enables the execution of five simultaneous tests, offering improved efficiency of high-volume test applications. The system has a twin-column construction with accurate crosshead guidance and a very rigid load frame. Five test curves can be plotted concurrently in real-time with the help of full computer control operation.

Source: Testometric Company Ltd

| |

X500-25MS |

X500-50MS |

| Force Capacity kN |

25 (5 x 5 kN) |

50 (5 x 10 kN) |

| Accuracy |

Better than +/- 0.5% of reading down to 1/1000th of load cell capacity |

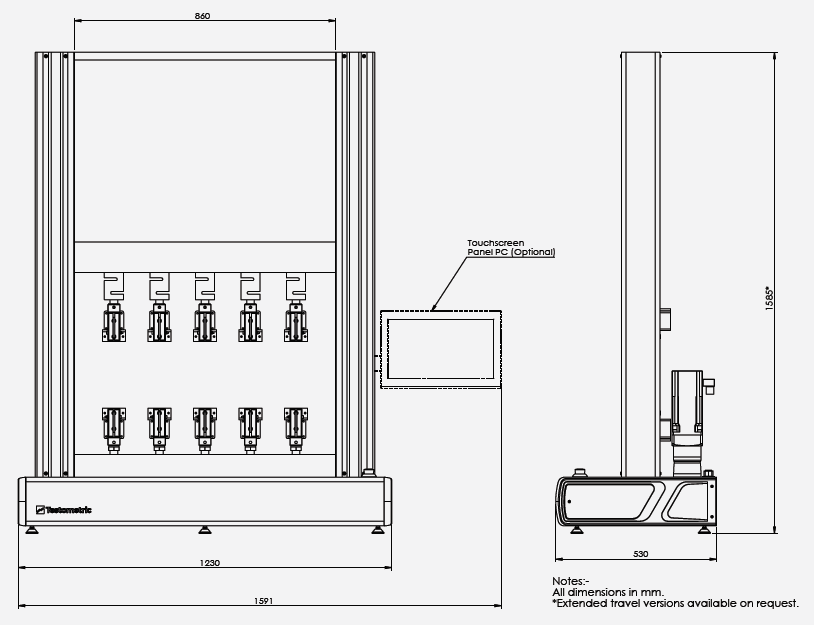

| Crosshead travel mm* |

950 |

950 |

| Vertical space mm |

1150 |

1150 |

| Position Control Resolution mm |

0.000001 |

0.000001 |

| Distance between columns mm |

860 |

860 |

| Minimum Speed mm/min |

0.00001 |

0.00001 |

| Maximum Speed mm/min |

1000 |

1000 |

| Speed Accuracy |

+/- 0.1% under stable conditions |

| Max force at full speed kN |

25 |

50 |

| Max speed at full load mm/min |

1000 |

1000 |

| Data Acquisition Rate (at PC) |

500 Hz as standard (optional 1000 Hz) |

| PC Connection |

Ethernet (or USB via adaptor) |

| Machine Configuration |

Twin-column, bench mounted (optional base cabinet available) |

| Frame Stiffness kN/mm |

120 |

120 |

| Weight kg |

320 |

320 |

| Operating Temperature °C |

0 to +55 |

| Operating Humidity |

90% relative humidity or less |

| Electrical Supply |

Dual input selectable 115 or 230 V, 1 ph 50/60 Hz |

| Power kW |

1 |

1 |

*Extended travel versions available on request.

Made to Measure

The X500 series is an entirely digital universal testing machine capable of precision control and accurate testing, which are powered by automated computer control, thus making operations simple.

- Automatic recognition of load cells and extensometers available with on-device storage of calibration parameters

- High-resolution load cells with improved accuracies of +/−0.5% down to 1/1000th of the load cell capacity

- Comes with software calibration check facility for instant verification of machine accuracy

- Accurate alignment and smooth running, guided by a crosshead guidance system

- High-efficiency pre-loaded self-cleaning ballscrews provided for quick, quiet testing; equipped with sealed-for-life lubricated end bearings

- Precision crosshead control through digital AC servo drive and brushless servo motor, providing 23-Bit positional control and maintenance-free operation

- High-speed data collection systems provided for up to four synchronous channels

- Load cells exhibit 800% overload capability without any damage

- Integral load cell cable routing in machine column helps avoid snagging and cable damage

- Six I/O channels are provided for more devices such as micrometers, extensometers, balances, calipers, etc.

- Comes with overtravel, overload, and impact protection

- Highly stiff loading frames equipped with precision ground steel guide rods and sturdy extruded support columns with T-slots for mounting accessories

- Telescopic covers offer additional protection for ballscrews against testing debris and dust

- Wide range of grips and fixtures for compression, tension, flexural, peel, shear, product testing, etc.

- An extensive range of contacting and non-contacting extensometers is available, inclusive of laser and video models

- Compact footprint design provides economy of floor and bench space

Image Credit: Testometric Company Ltd

1. Available at additional cost. Machine can alternatively be controlled using a standard PC or laptop (not supplied).

2. Machine shown with ACPN4 pneumatic grips (available separately).

X500 MS Dimensions

Image Credit: Testometric Company Ltd

Large range of grips and fixtures available. Image Credit: Testometric Company Ltd

High-speed modular electronics. Image Credit: Testometric Company Ltd

Comprehensive range of extensometry. Image Credit: Testometric Company Ltd

Built for Precision

Force Measurement

The system has been universally calibrated and is better than Grade 0.5 EN 7500-1, AFNOR A03-501, and DIN 51221 ASTM E-4. It offers a minimum range of 0.4%–100%. The system can automatically identify load cells, ensures a resolution of 1 part in 500000, and offers electronic load cell protection.

Extension Measurement

The X500 MS features a full frame length to a maximum resolution of 0.000001 mm (selectable) and ensures an accuracy of +/−0.01 mm. The system is available in absolute, relative, and auxiliary modes in mm, inch, and percent.

Speed Control

The X500 MS system offers the best-in-class low-speed performance with speeds as low as 0.00001 mm/minute and comes with drive system temperature and current protection.

Load Frame

The X500 is built from precision ground steel guide rods and a sturdy extruded support column, forming a rigid frame. It has a frame stiffness of up to 120 kN/mm plus an integrated K factor facility. The frame also features a re-circulating ball screw with bellows, total travel trips, electronic limit trips, and customer-programmable safety stops.

Electronics System

Quick data transfer to the PC (up to 1000 Hz) is made possible by the modular electronics system, through a high-speed Ethernet connection. The comprehensive input options facilitate the connection of a vast range of accessories and extensometers through simple plug-in interface modules.

Safety Features

The X500 system comes with extensive safety features, thereby ensuring the maximum grade of operator safety, including overload/impact detection, E-Stop, and programmable extension limits. The safety standards fully comply with global safety directives such as the 2006/42/EU Machinery Directive, 2014/35/EU Low Voltage Directive, and 2014/30/EU Electromagnetic Compatibility Directive.

Optional Touchscreen Panel PC

The X500 MS system turns into a rugged, autonomous system without requiring a laptop or an external PC upon pairing with an optional IPC3 industrial-grade Panel PC including a touchscreen control.

The latest version of the Windows 10 operating system and the full version of Testometric’s winTest software enable complete control of the test machine, with storage and access to limitless test methods and results.

The integrated mounting arm extending to the machine column T-slots can be fully adjusted for height, reach, and viewing angle, thereby making a better ergonomic working position for the user.

Specifications

- QM87 Chipset, 4 x USB3.0, 3 x COM ports [RS232], 2 x GigaLAN

- Display 15.6″ 1366 x 768 panel resistive touch screen with anti-reflective, dirt-repellent screen protection

- CPU-i5-4300M Intel Core i5 Processor, 2.6 GHz

- 4 GB, 1600 MHz SODIMM DDR3 204-pin

- QM87 Chipset, 4 x USB3.0, 3 x COM ports (RS232), 2 x GigaLAN

- 2.5″ 250 GB, Solid State Disk (SSD), SATA III 6 GB/second

Image Credit: Testometric Company Ltd

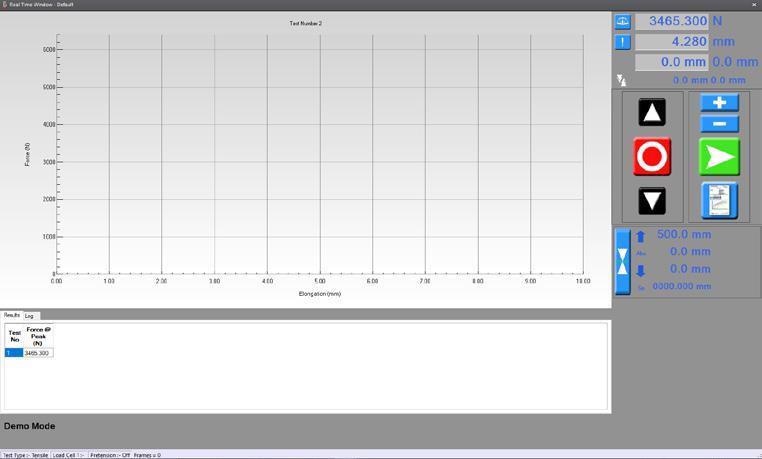

Tried and Tested Software

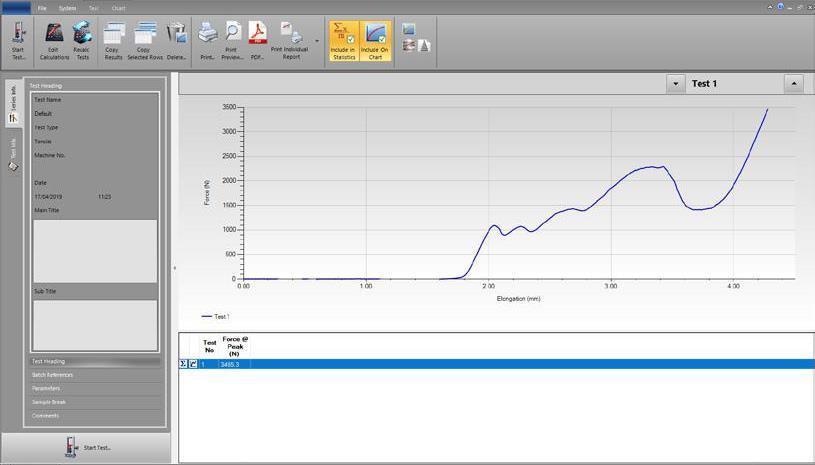

All models in the Testometric range come with an all-in-one winTest analysis software package.

The winTest Analysis has undergone several developments over the years and hence offers flexible and intuitive software to suit all kinds of material testing. It comes with built-in test methods such as compression, tensile, peel, flexural, tear, shear, creep, cyclic, and multi-stage tests.

The system can perform a wide range of industry test methods and enables creating and storing a limitless number of additional test methods. The software can automatically store all test data and can easily export it to other software packages such as excel, word, access, and SPC systems for improved report generation.

Integration of the RCE remote connection option will help enable all machines to form a web link directly to Testometric for monitoring, remote investigation, and software updates.

Real-time test screen. Image Credit: Testometric Company Ltd

Test analysis screen. Image Credit: Testometric Company Ltd