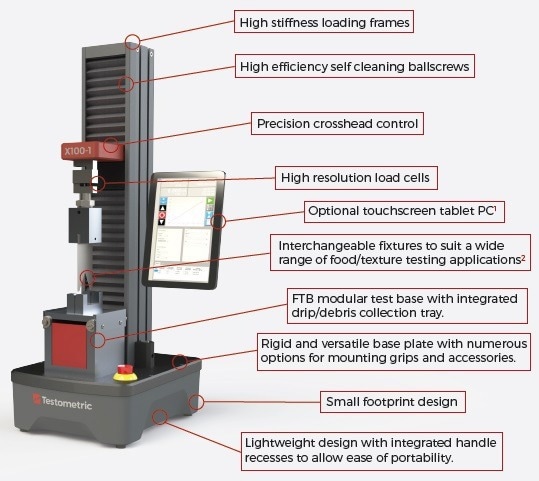

The X100-FTA from Testometric is a Texture Analyser based on the X100-1 Universal Testing Machine, with a modular base to enable interchangeable fixtures for common food and texture testing applications (e.g. Warner-Bratzler Shear, Magnus Taylor Puncture, Kramer Shear, Back/Forward extrusion tests, and so on). Full computer control and a precision AC servo drive system are included.

Source: Testometric Company Ltd

| X100-FTA |

| Force Capacity kN |

1 |

| Accuracy |

Better than +/- 0.5% of reading down to 1/1000th of load cell capacity |

| Included Load Cell |

500N or 1000N (to be selected) |

| Included Accessories |

FTB modular test base fixture with integrated debris tray, WinFood software module. |

| Optional Fixtures (to be selected) |

CPS Compression Platens, WBST Warner-Bratzler Shear, MTPP Magnus Taylor Puncture, OTMS Forward Extrusion Food Cell, BEFS Back Extrusion Food Cell, KTSS Kramer Shear Cell, VB Variable Span 3-point Bend Fixture (others available on request) |

| Crosshead travel mm* |

420 |

| Position Control Resolution mm |

0.0001 |

| Throat depth (force axis to column) |

81 |

| Minimum Speed mm/min |

0.001 |

| Maximum Speed mm/min |

1000 |

| Speed Accuracy |

+/- 0.1% under stable conditions |

| Data Acquisition Rate (at PC) |

500 Hz |

| PC Connection |

USB |

| Machine Configuration |

Single-column, bench mounted |

| Frame Stiffness kN/mm |

5 |

| Weight kg |

25 |

| Operating Temperature °C |

-10 to +40 |

| Operating Humidity |

+10 to +90% non-condensing |

| Electrical Supply |

100-240 V, 1 ph 50/60 Hz |

| Power kW |

0.2 |

*Extended travel version available on request

Made to Measure

The X100-FTA is a completely digital testing system with greater precision control and accuracy, as well as automated computer control of test techniques for ease of use.

Load cells with high resolution have an accuracy that surpasses +/-0.5% down to 1/1000th of the load cell capacity.

The device also has automatic load cell and extensometer recognition, with on-device calibration parameter storing, as well as software calibration check capability for quick machine accuracy verification.

Load cells can withstand an overload of 800% without damage, and there are pre-loaded self-cleaning ballscrews with high efficiency for fast, quiet testing. End bearings are sealed for life and lubricated.

A crosshead guidance system ensures exact alignment and smooth operation.

Precision crosshead control is provided via a digital AC servo drive and a brushless servo motor, which provide maintenance-free operation and positional control at 20,000 pulses/rev.

X100-FTA has systems for high-speed data collecting with up to four synchronous channels and an expansion channel for extra devices like extensometers, micrometers, calipers, balances, and so on.

Loading frames have high stiffness, robust specialized steel crossheads, and sturdy extruded support columns with T-slots for accessory mounting.

Overload, overtravel, and impact protection are all available.

Telescopic covers provide additional dust and testing debris protection for ballscrews.

Bench space is saved with the X100-FTA's small footprint design.

The included “WinFood” software module offers complete data analysis for food/texture testing applications, including automatic calculation of common qualities like hardness, chewiness, toughness, and durability.

Image Credit: Testometric Company Ltd

1 Available at additional cost. Machine can alternatively be controlled using a standard PC or laptop (not supplied).

2 WBST Warner-Bratzler Shear Test Fixture shown, others available.

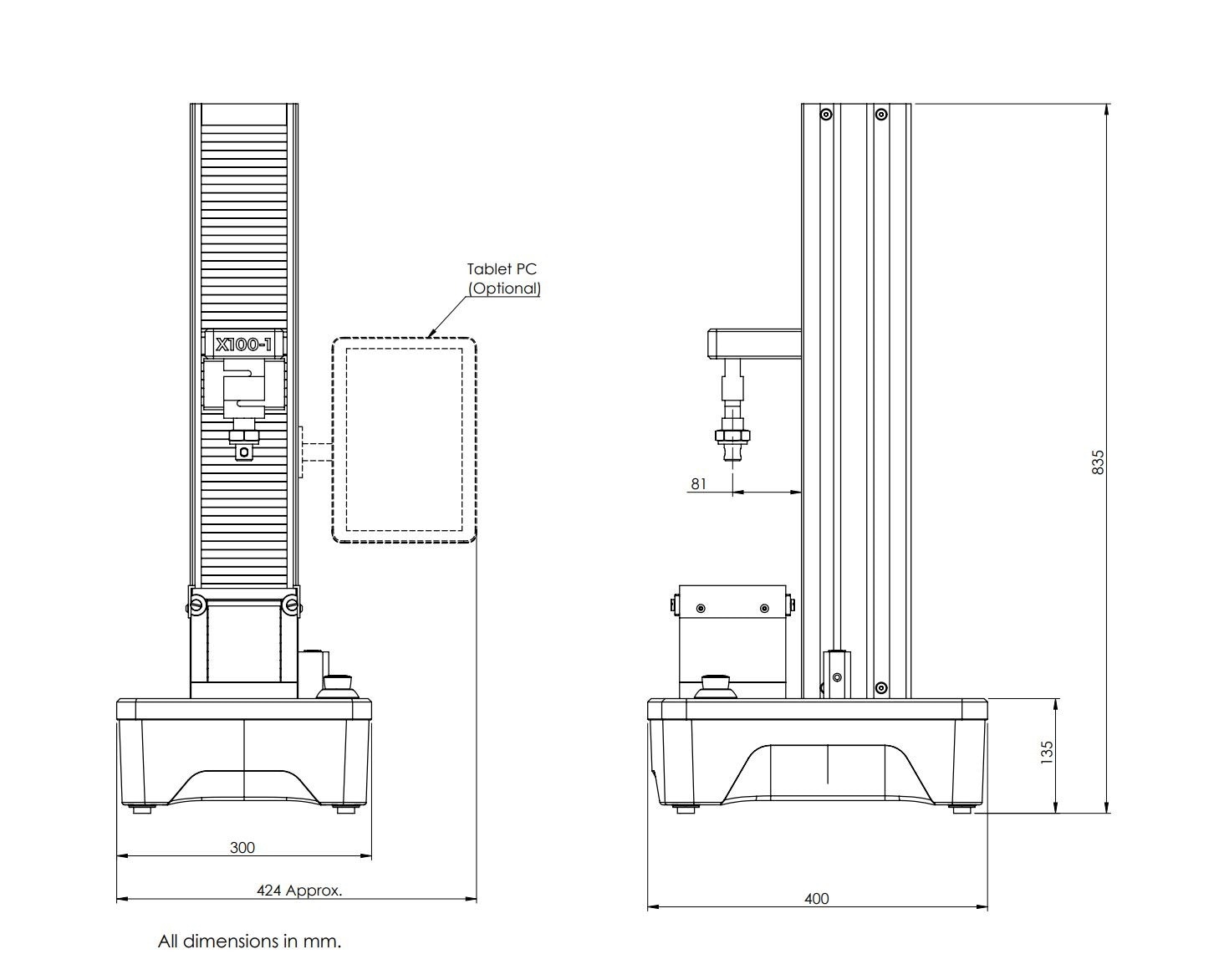

X100-FTA Dimensions

Image Credit: Testometric Company Ltd

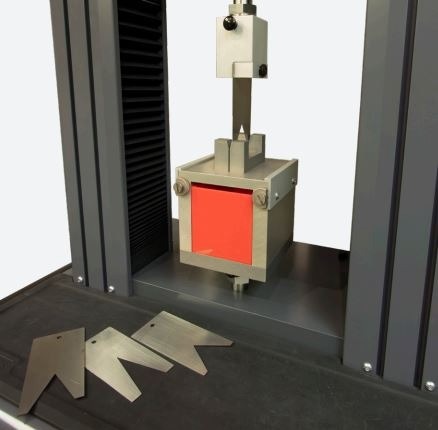

Warner-Bratzler Meat Shear

OTMS “Ottawa” Forward Extrusion Fixture

Back Extrusion Cell

Above: Examples of Typical Fixtures. Image Credits: Testometric Company Ltd

Built for Precision

Force Measurement

Universally Calibrated, more effective than Grade 0.5 EN 7500-1, DIN 51221 ASTM E-4. AFNOR A03-501. Minimum range: 0.4 to 100%. Load cell identification is done automatically. The resolution is 1 part in 500000. Protection for electronic load cells.

Extension Measurement

Full frame length with a resolution of up to 0.0001 mm (selectable). Accuracy is +/- 0.01 mm. Absolute, relative, and auxiliary modes in %, mm, and inch.

Speed Control

Low-speed performance is outstanding, with speeds as low as 0.001 mm/min. Drive system temperature and current protection.

Load Frame

Rigid frame with sturdy extruded support column and precise linear guidance system. Frame rigidity of 5kN/mm with built-in K factor. Ball screw with bellows for recirculating. Limit trips, total travel trips, and customer-programmable safety stops are all available.

Electronics System

The modular electronics system transfers data to the PC at a high rate (500 Hz) via a high-speed USB connection. Extensive input possibilities enable simple plug-in interface modules to link a broad range of extensometers and accessories.

Safety Features

Comprehensive safety features, such as E-Stop, programmable extension limits, and overload/impact detection, ensure the highest standards of operator safety. Complete compliance with global safety regulations: 2006/42/EU Machinery Directive, 2014/35/EU Low Voltage Directive, and 2014/30/EU Electromagnetic Compatibility Directive.

Optional Tablet PC

When combined with the optional TPC1 tablet PC with touchscreen control, the machine transforms into a powerful independent system that eliminates the need for an external PC or laptop.

The system offers a wholly-featured test environment with the ability to develop and store an unlimited number of methods and results by utilizing a specialized version of WinTest software tailored for touchscreen use.

The provided mounting arm, which attaches to the machine column T-Slots, is height, reach, and viewing angle adjustable, allowing the user to select the most ergonomic working position. The machine can also be connected to a standard desktop PC or laptop through the sophisticated WinTest EC software.

Image Credit: Testometric Company Ltd

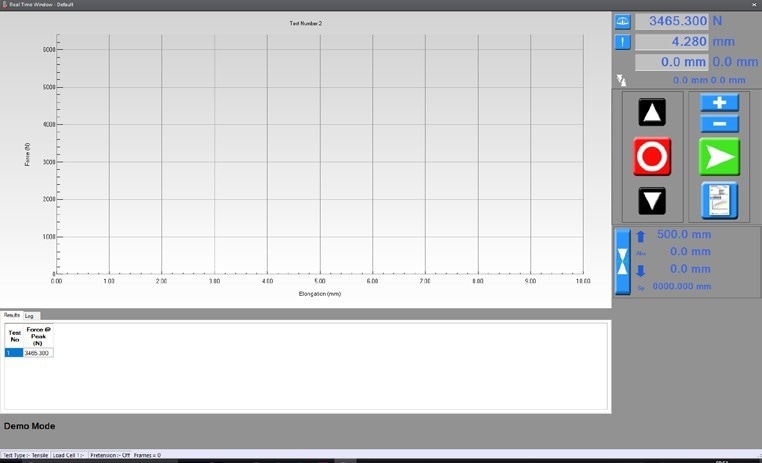

Tried and Tested Software

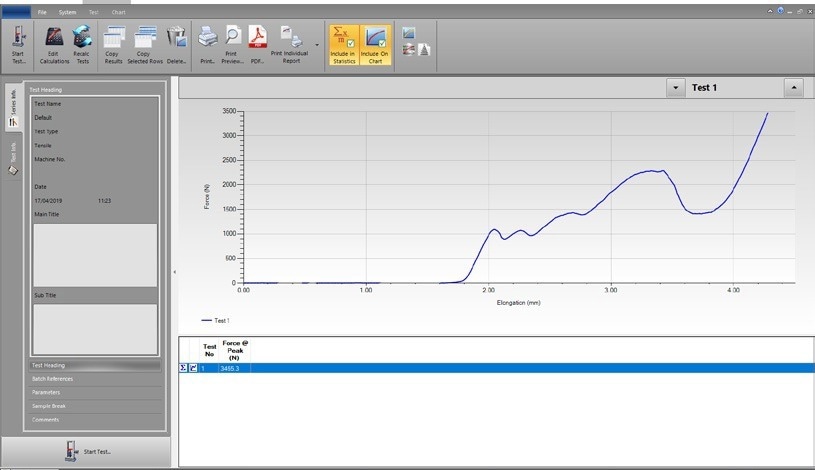

The comprehensive winTest Analysis software suite is included with all Testometric models.

WinTest Analysis, the result of many years of continuous development, is a versatile and user-friendly software package suitable for all forms of material testing. Tensile, compression, peel, flexural, shear, tear, creep, cyclic, and multi-stage tests are all integrated.

It features a large number of industry-standard test methods as well as the ability to build and save an unlimited number of additional test methods. All test data is automatically stored, and it is simple to export to other software packages like Word, Excel, Access, and SPC systems for increased report generation.

All machines can now be web-linked directly to Testometric for remote investigation, monitoring, and software upgrades with the addition of the RCE remote connection option.

Real time test screen. Image Credit: Testometric Company Ltd

Test analysis screen. Image Credit: Testometric Company Ltd

Standing the Test of Time

Image Credit: Testometric Company Ltd

Since its inception in 1970, Testometric has been engaged in the design and manufacture of testing machines and quality control equipment.

Fifty years of continuous development have yielded a major product range of universal strength testing machines for tension, compression, flexure, shear, and product testing. Over 100 countries employ Testometric’s machines, which are supported by a network of offices and licensed agencies.

Testometric is well-established in many industries and educational sectors, and they have an amazing reputation for product quality, creativity, and excellent customer service.