Users can acquire greater levels of versatility for their scientific and industrial research with the newest 3D X-Ray microscope models in the ZEISS Xradia Versa series.

By leveraging industry-leading resolution and contrast, the ZEISS Xradia 610 and 620 Versa push the boundaries of non-destructive sub-micron scale imaging.

Highlights

Extending the Limits of Micro- and Nano-CT Solutions

- Better flux and quicker scans without losing clarity

- Sub-micron level non-destructive microscopy of completely intact samples

- Image quality with high throughput

- Upgradable and expandable in response to upcoming advances and expansions

- True spatial resolution of 500 nm with a voxel size of 40 nm as the smallest attainable size

- In situ imaging for non-destructive microstructure classification throughout, in controlled settings

- Outstanding resolution over an extensive variety of sample types, proportions, and operational ranges

Highest Resolution and Flux

While traditional tomography relies on single-stage geometric magnification, the Xradia Versa uses new two-stage magnification optics and a high flux X-Ray source to produce images with sub-micron scale resolution in less time.

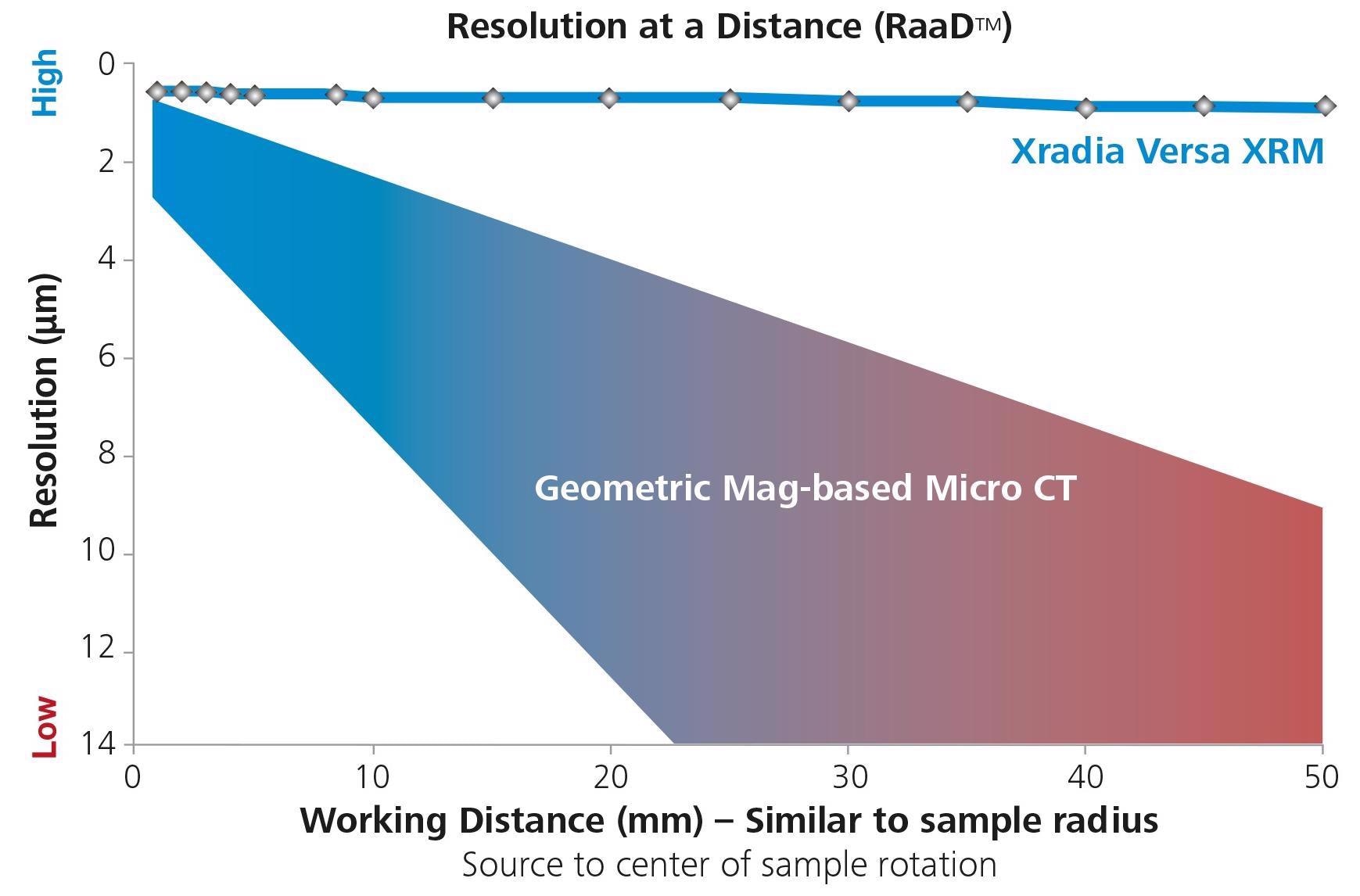

The Resolution at a Distance (RaaD) architecture enables high-resolution 3D imaging of larger, denser objects like entire components and machinery. The additional flat panel extension (FPX) enables fast scanning of large samples (up to 25 kg) as well as navigation to key sequences.

New Degrees of Freedom

Use the industry’s most comprehensive 3D X-Ray imaging solution for sophisticated scientific and industrial research to achieve breakthrough material and property characterization, boost absorption, and phase contrast.

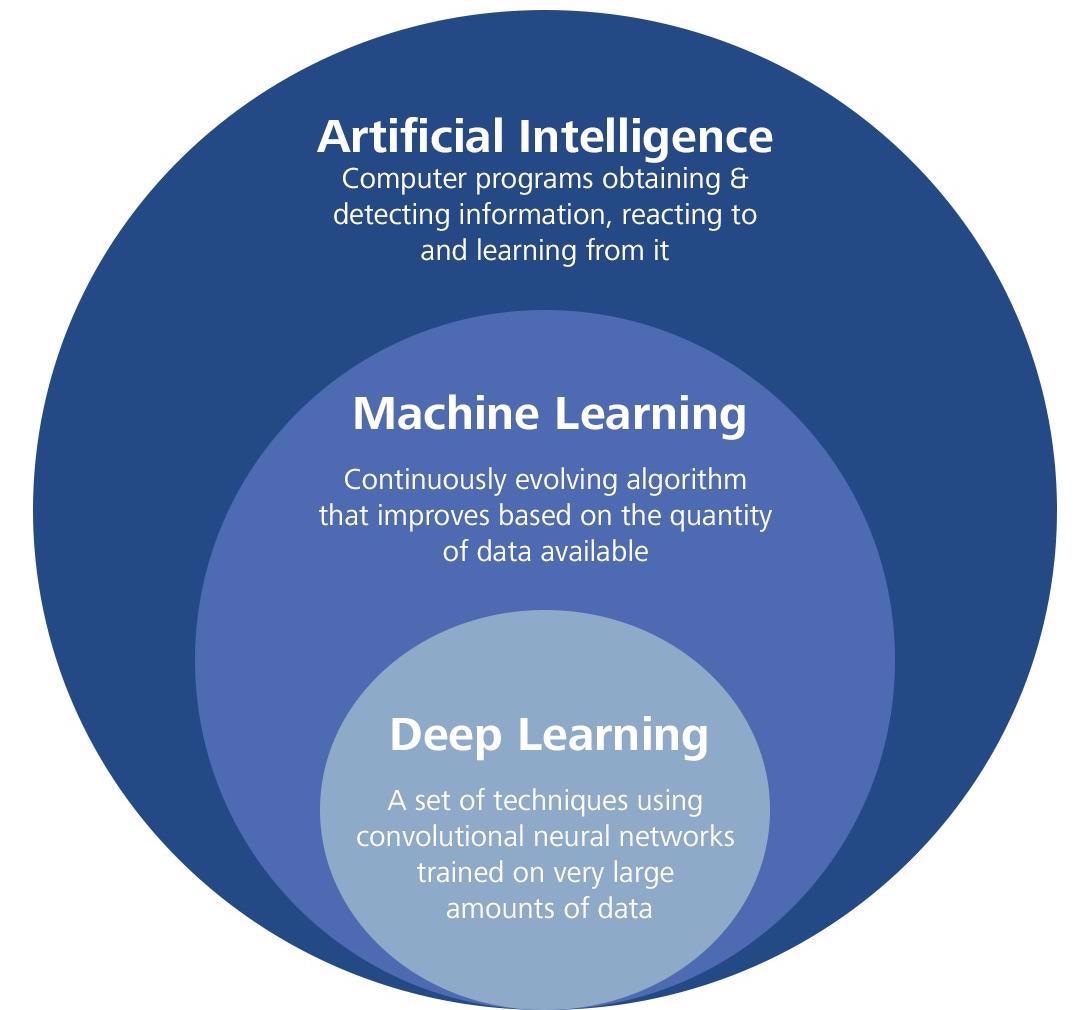

Diffraction 3D crystallographic information can be revealed using contrast Tomography. The user can increase the speed and precision of scanning large or infrequent samples using advanced acquisition methods. Machine learning methods can be used to help with sample post-processing and segmentation.

Premier 4D/In Situ Solution

The ZEISS Xradia 600 Series Versa can characterize 3D microstructures of materials non-destructively (in situ) and analyze formation development over time (4D).

The Xradia Versa uses Resolution at a Distance to maintain the best resolution over long distances, enabling it to cater to samples, environmental chambers, and high accuracy in situ load rigs without sacrificing resolution.

The Versa easily connects with other ZEISS microscopes to overcome multi-scale correlative imaging issues.

Application Examples

ZEISS Xradia 610 and 620 Versa at Work

Electronics and Semiconductor Packaging

Typical Tasks and Applications

- For reverse engineering and hardware security, examine printed circuit boards

- Image non-destructively across length scales from module to package to interconnect for submicron-resolution defect analysis at speeds that can supplement physical cross-sectioning

- Conduct structural and failure analysis of advanced semiconductor packages, including 2.5/3D and fan-out packages, for process development, yield enhancement and construction analysis.

- Improve comprehension of defect sites and distributions by seeing limitless virtual cross-sections and plan view photos from any angles desired.

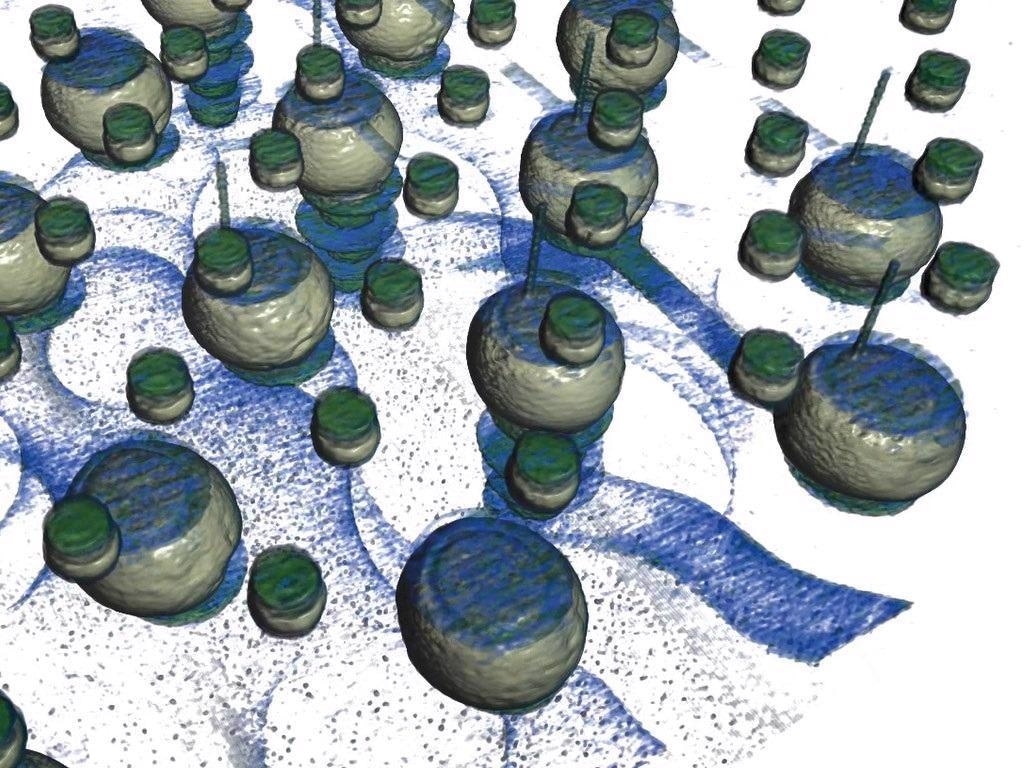

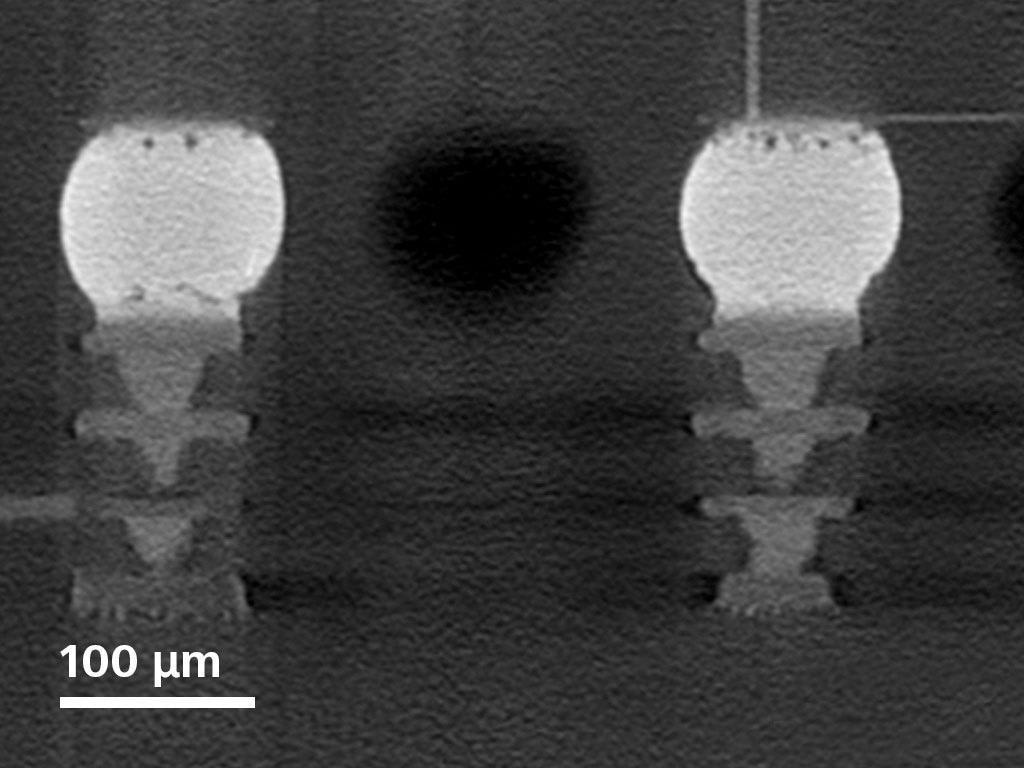

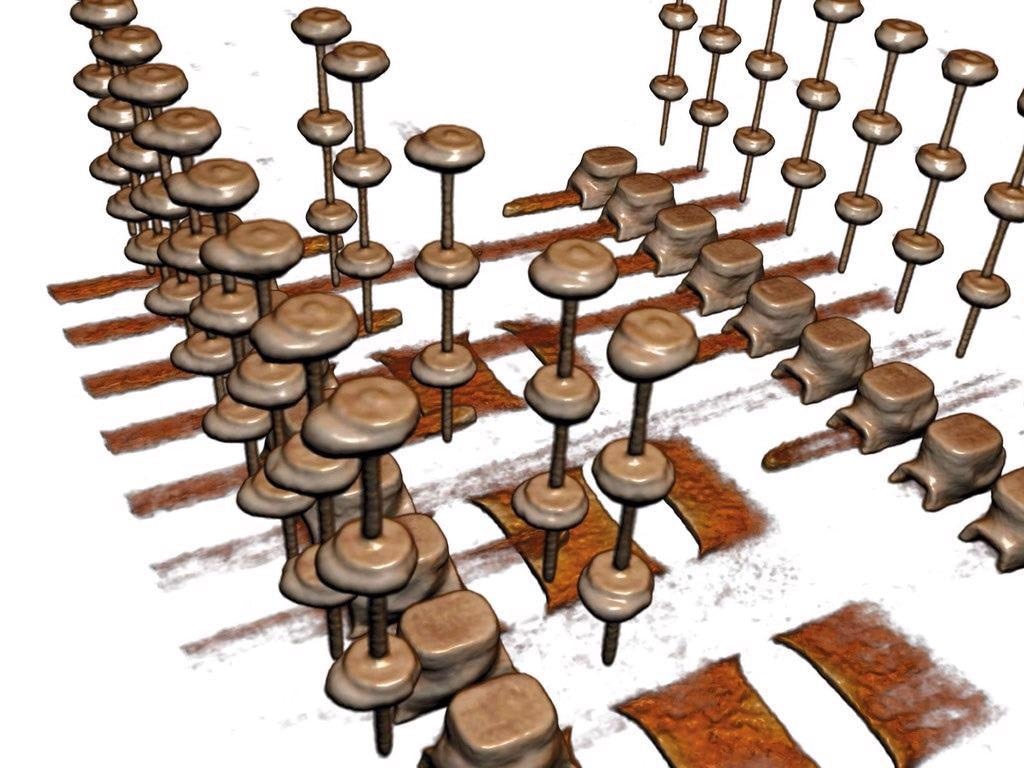

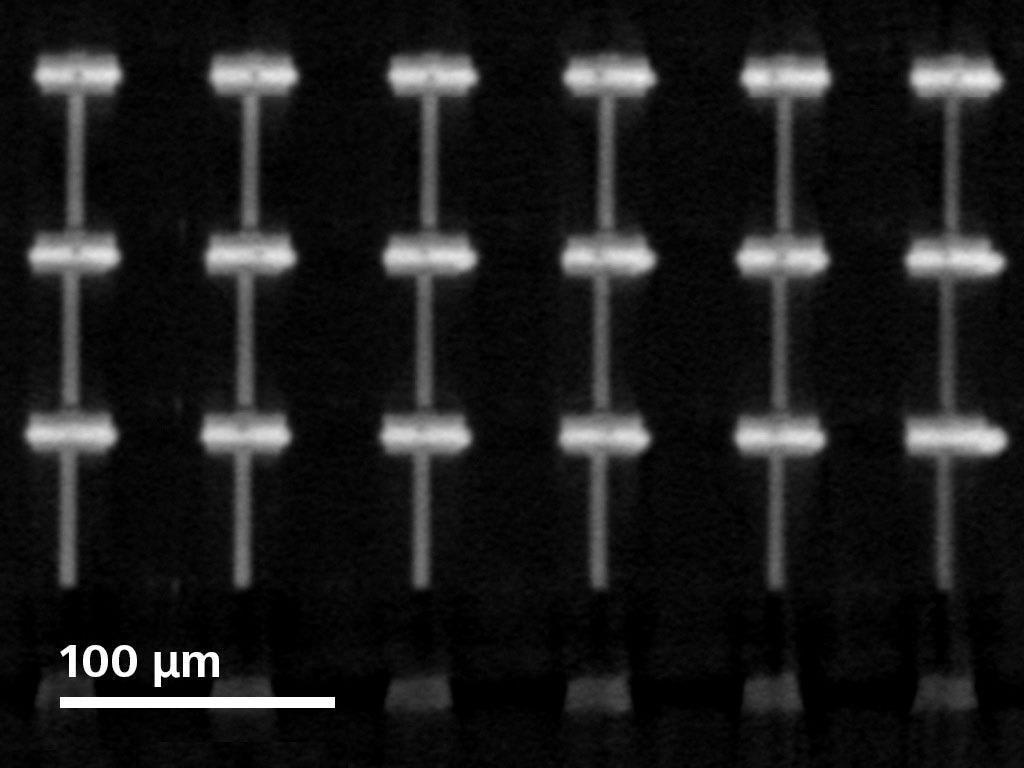

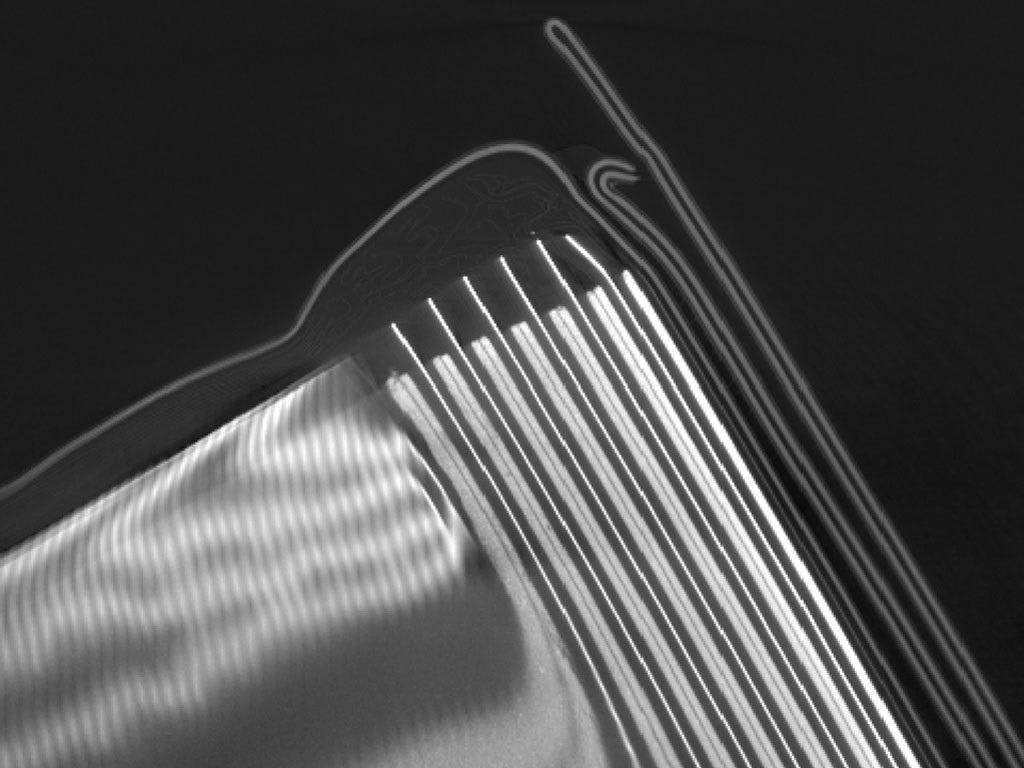

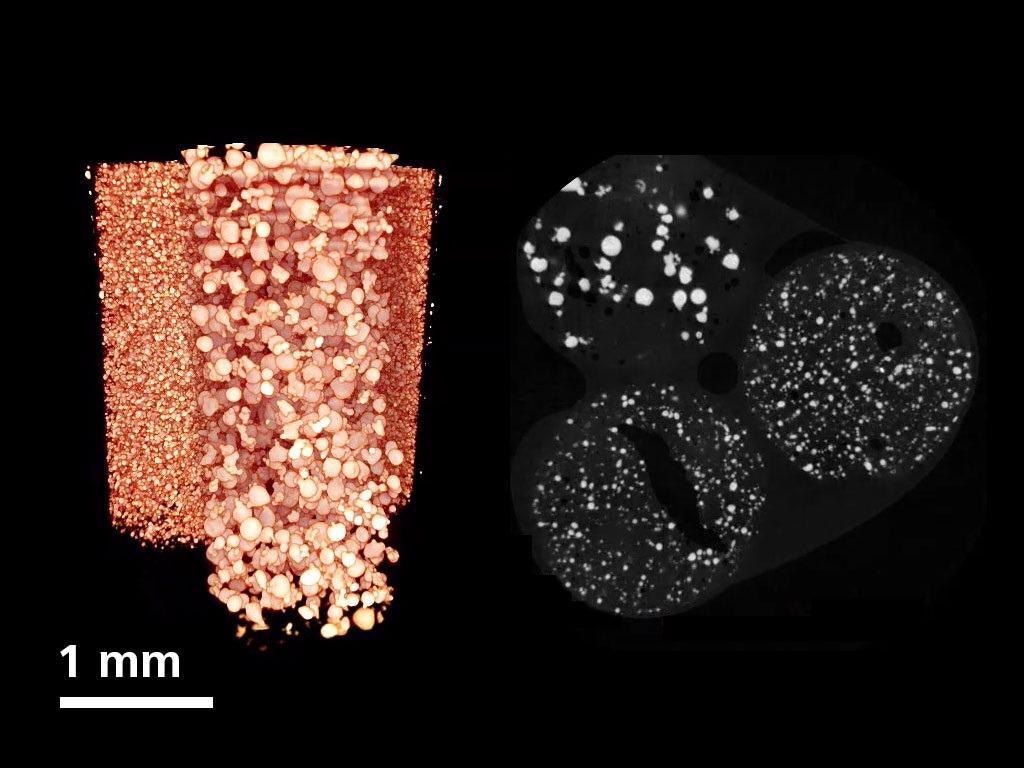

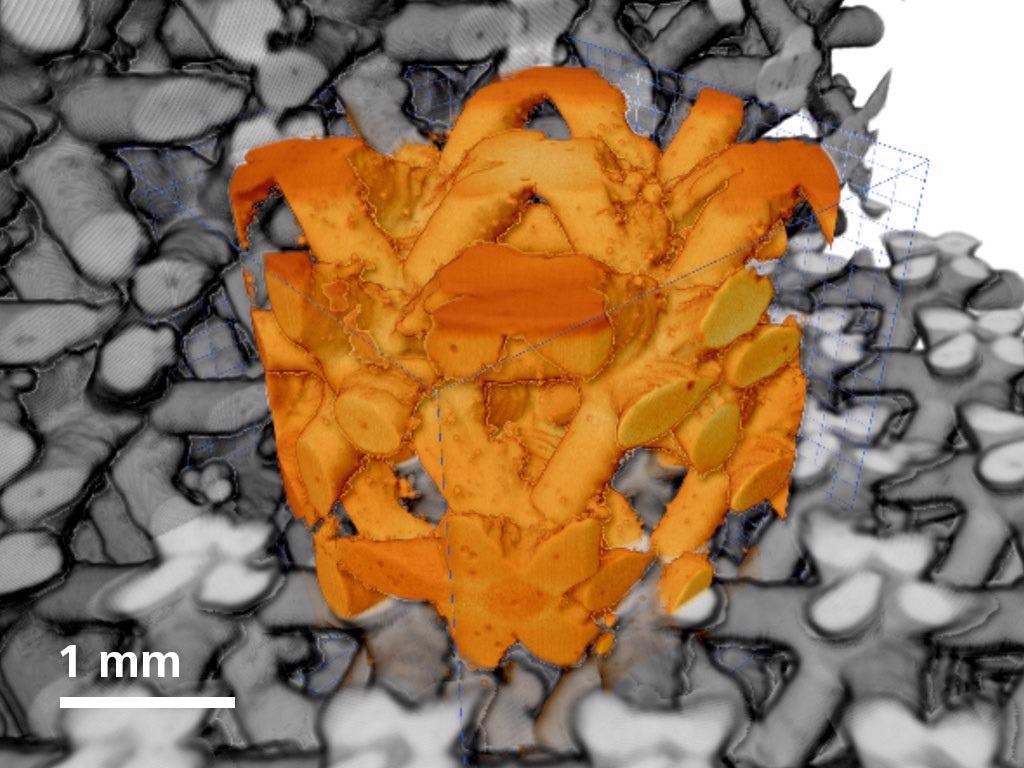

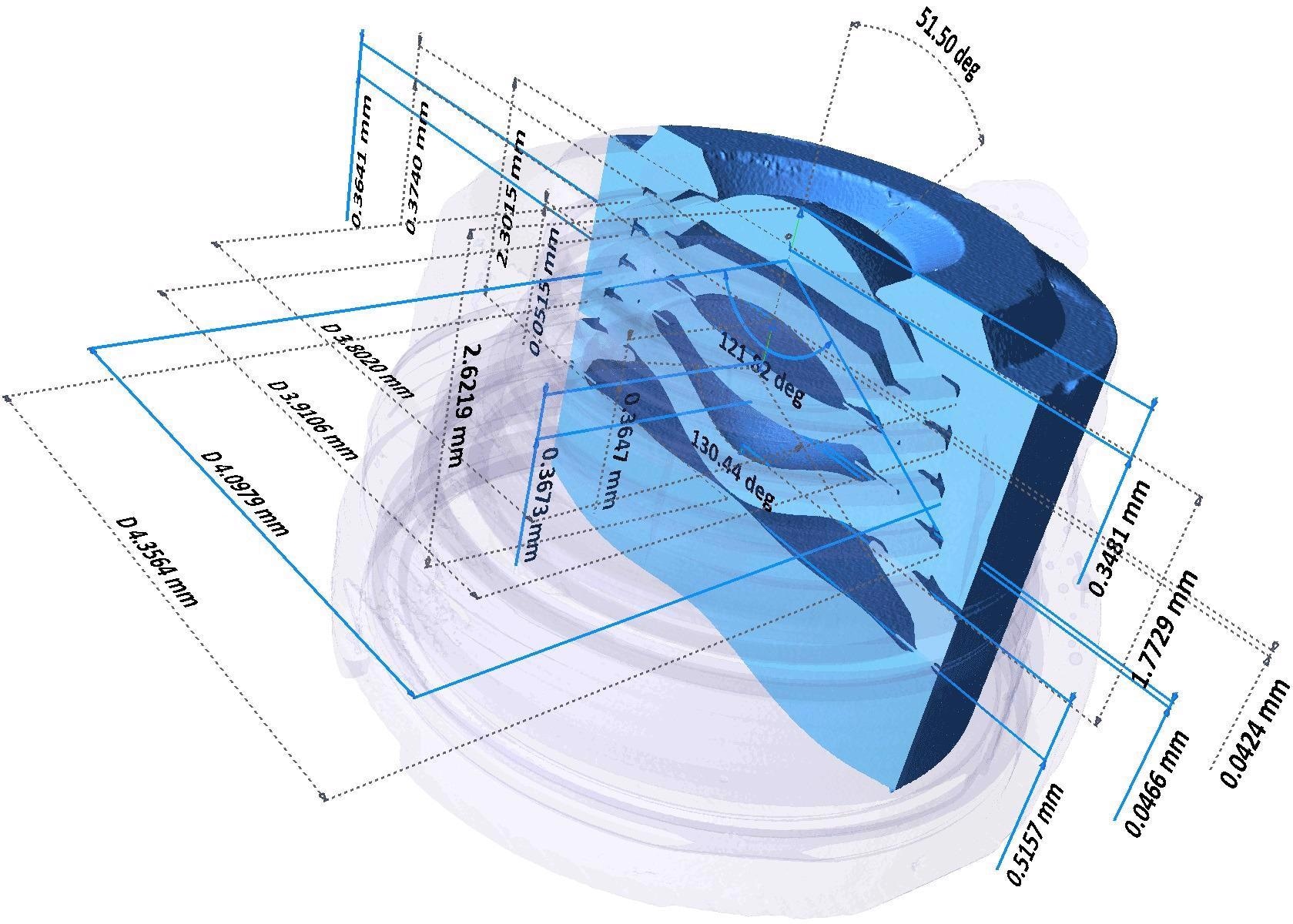

Visualization of C4 bumps, TSVs, and Cu-pillar micro bumps in a 2.5D package, enabling high-resolution views from within the intact package, 1 µm/voxel. Image Credit: Carl Zeiss Raw Materials

Virtual cross section from the 2.5D package reveals solder cracks and voids in C4 bumps. Image Credit: Carl Zeiss Raw Materials

DRAM package interconnects within a 10 mm × 7 mm × 1 mm package containing a 4-die stack. Solder extrusion is easily visualized in 3 dimensions, 0.8 µm/voxel. Image Credit: Carl Zeiss Raw Materials

Virtual cross section of micro bumps in a DRAM package. TSVs are 6 μm in diameter and micro bumps average 35 µm in diameter. Small solder voids of 2 μm are visible. Image Credit: Carl Zeiss Raw Materials

Lithium-Ion Batteries

Typical Tasks and Applications

- Assessment for safety and quality: Identifying debris, particle development, burrs at the electrical contact or damage to the polymer separator.

- Lifetime and aging impacts: Longitudinal studies on the effects of aging

- Recipe creation and supply chain management: Assessment of intact samples for efficient supplier control, revealing recipe alterations or cost savings that may impair effectiveness or longevity.

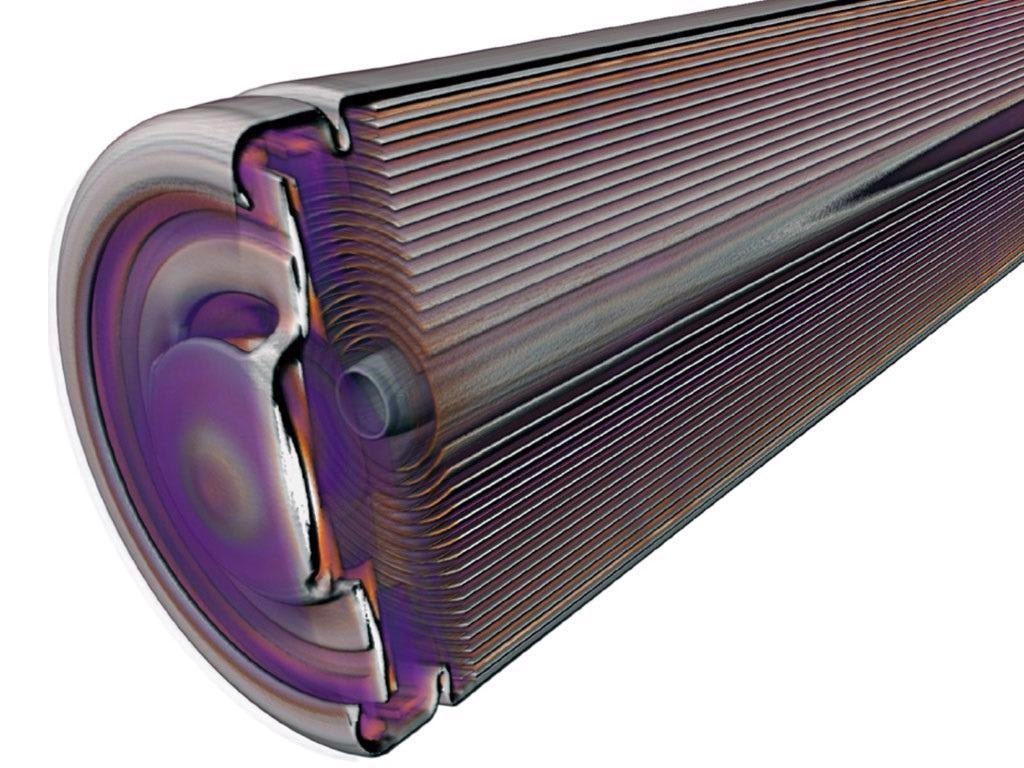

Intact cylinder cell (160 kV)—welding burrs, metallic inclusions, folds and kinks in conductive layers. Image Credit: Carl Zeiss Raw Materials

Large pouch cell (120 kV)—failure analysis, swelling, wetting, electrolyte gas evolution. Image Credit: Carl Zeiss Raw Materials

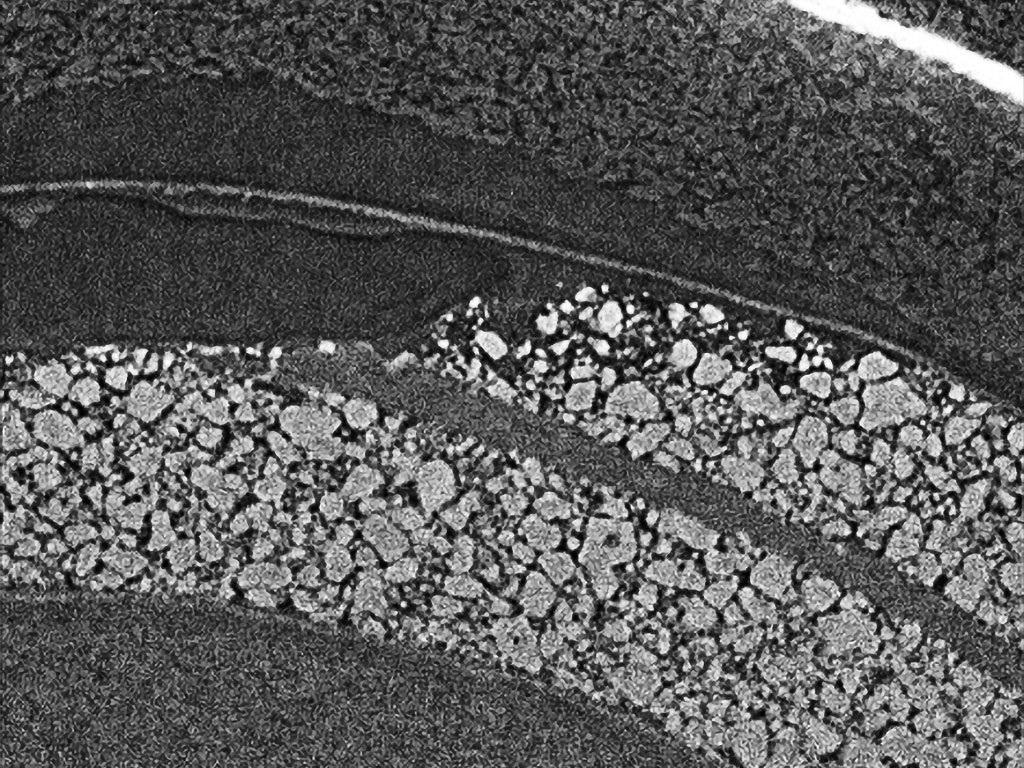

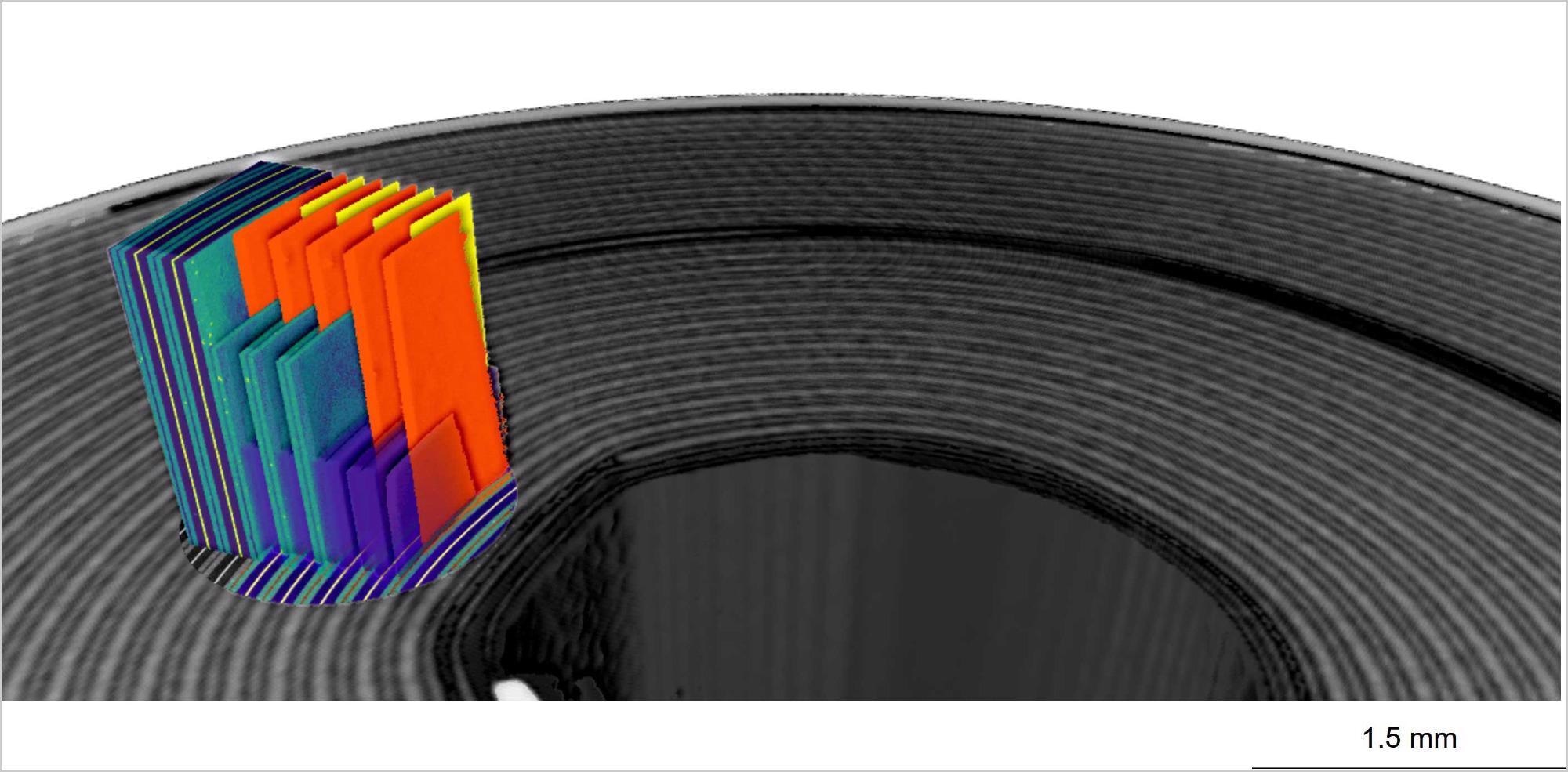

Small pouch cell (80 kV)—in situ microstructure, aging effect at cathode grain level, separator layer. Image Credit: Carl Zeiss Raw Materials

Small pouch cell: 0.4× overview scan; 4× Resolution at a Distance; 20× Resolution at a Distance. Image Credit: Carl Zeiss Raw Materials

Additive Manufacturing

Typical Tasks and Applications

- Studying the surface roughness of interior components that are inaccessible via other methods

- 3D imaging for comparison with the nominal CAD model

- Unmelted particles, high-Z inclusions and voids are detected

- To identify optimal process parameters, a detailed shape, size and volume distribution analysis of particles in an Additive Manufacturing (AM) powder bed is performed

- Microstructural study of AM parts using high-resolution, non-destructive imaging

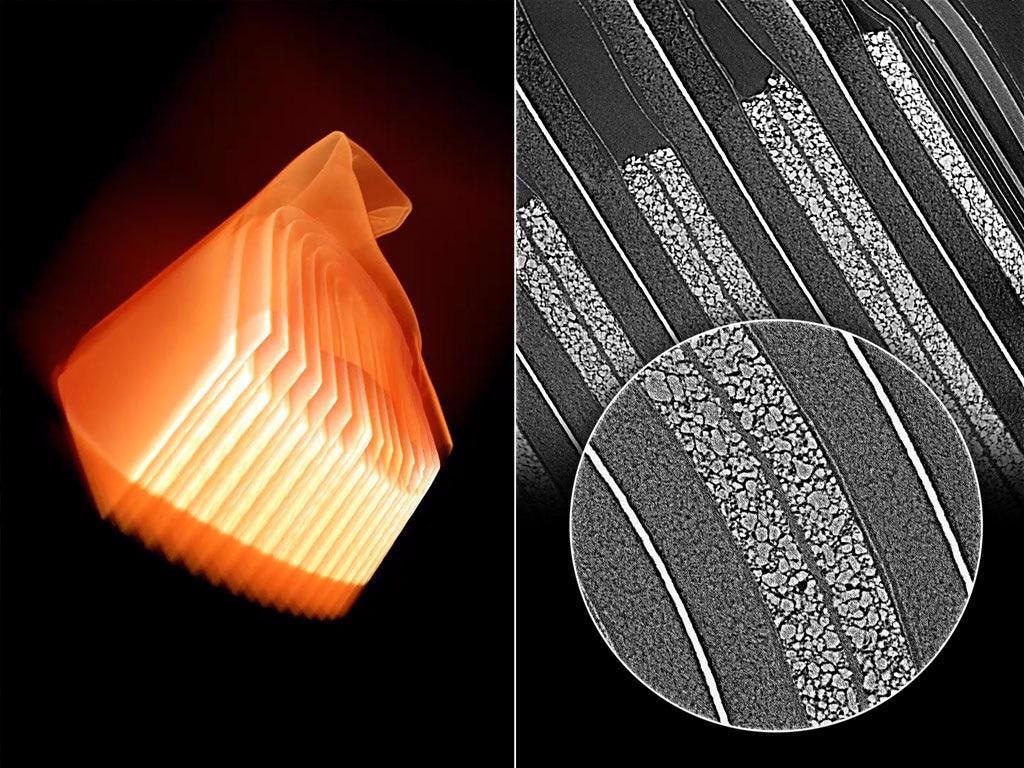

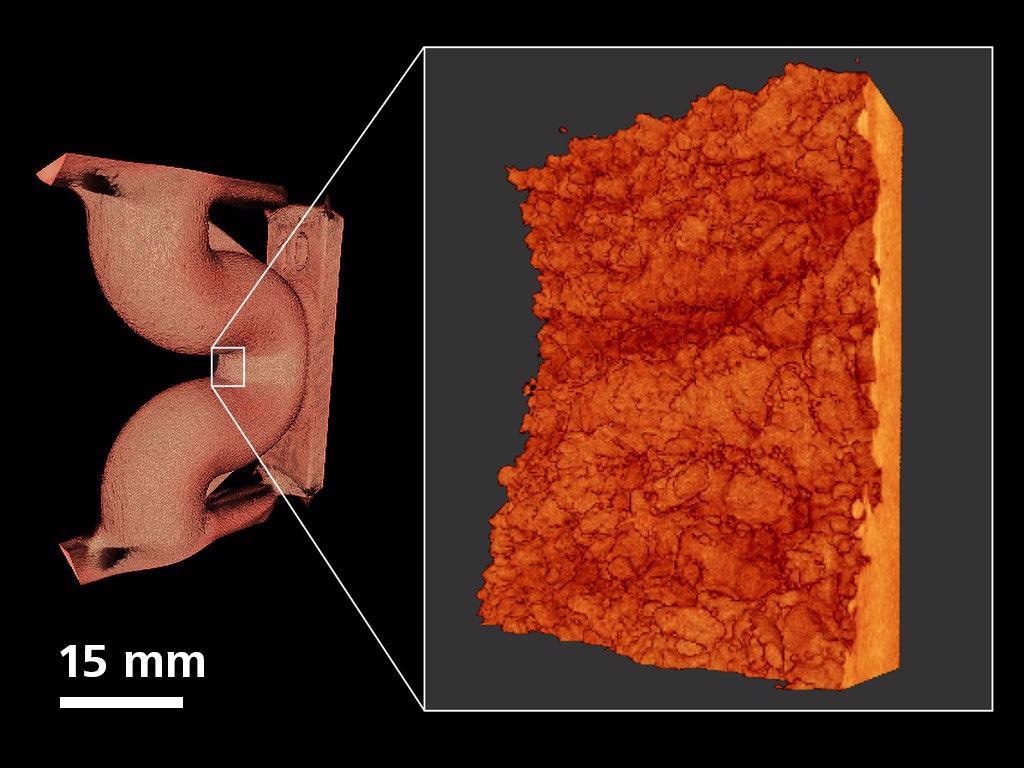

Surface roughness evaluation of an AM printed duct (Ti-6Al-4V); high resolution scan acquired at ~1.7 mm voxel over a ~3.4 mm area. Image Credit: Carl Zeiss Raw Materials

Imaging of different A205 AM powder qualities at 3.9 µm voxel resolution. Image Credit: Carl Zeiss Raw Materials

Inner structure of an AM manufactured aluminum gear wheel; 3 µm voxel resolution imaging is used to see unmelted particles, High-Z inclusions, and small voids. Image Credit: Carl Zeiss Raw Materials

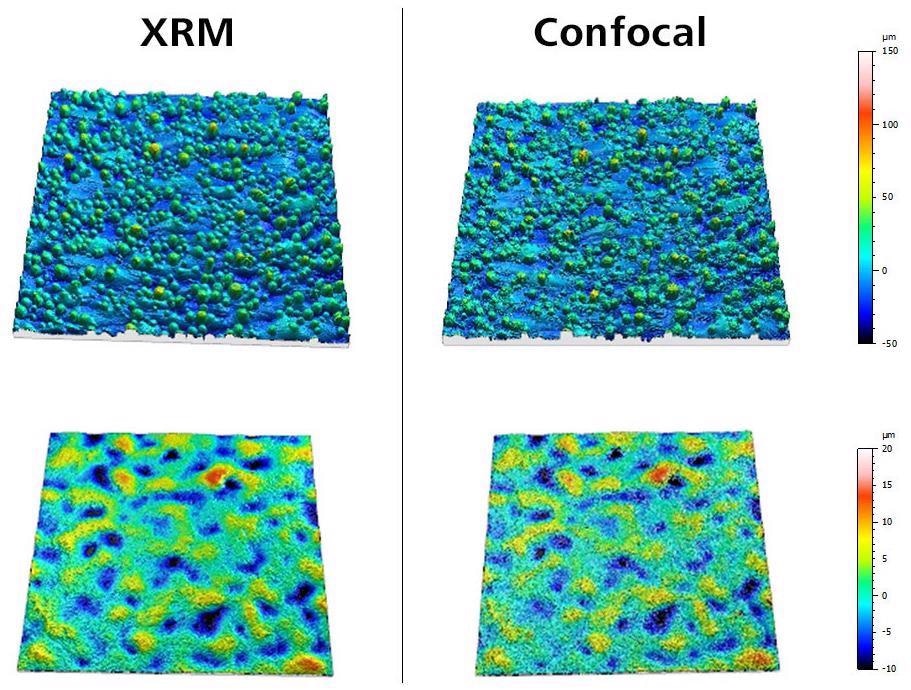

ISO 25178 surface roughness evaluation of a Ti-6Al-4V test sample. Results are very similar between XRM and ZEISS Smartproof 5 confocal microscope. Image Credit: Carl Zeiss Raw Materials

Materials Research

Typical Tasks and Applications

- Observe characteristics at different scales of length

- Measure microstructural evolution

- Demonstrate the three-dimensional structure

- Inspect the failure procedures, degradation incidences, and internal defects

- Perform in situ and 4D time-dependent investigations to understand the effects of heating, desiccation, cooling, wetting, compression, tension, drainage, imbibition, and other simulated environmental research

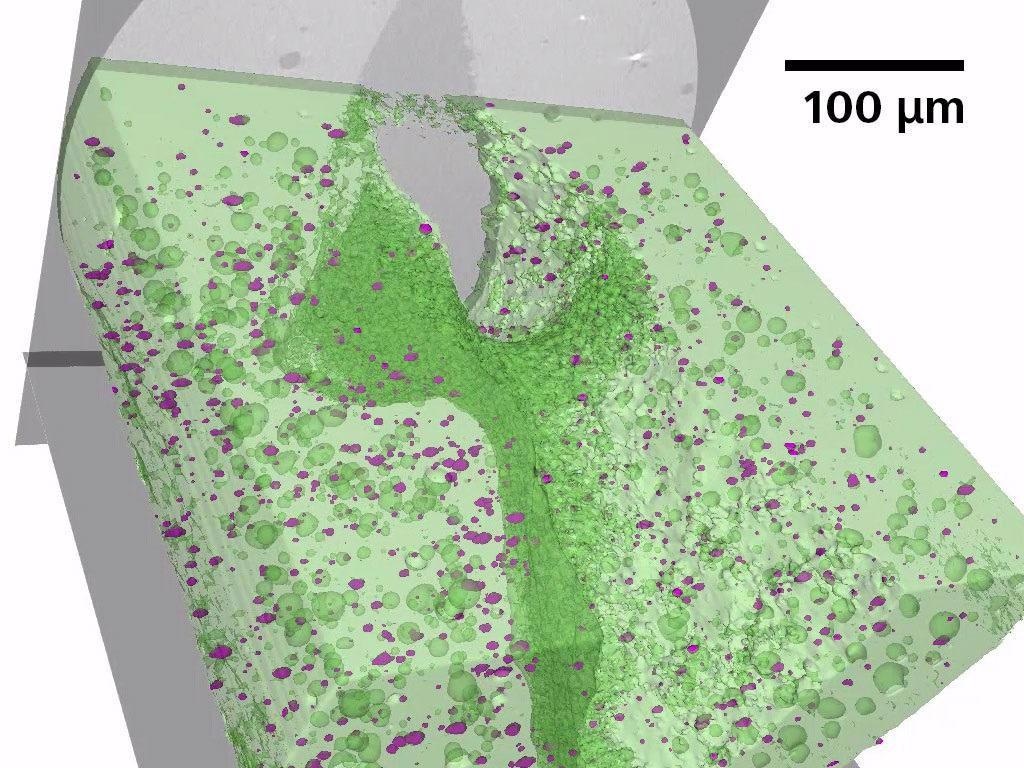

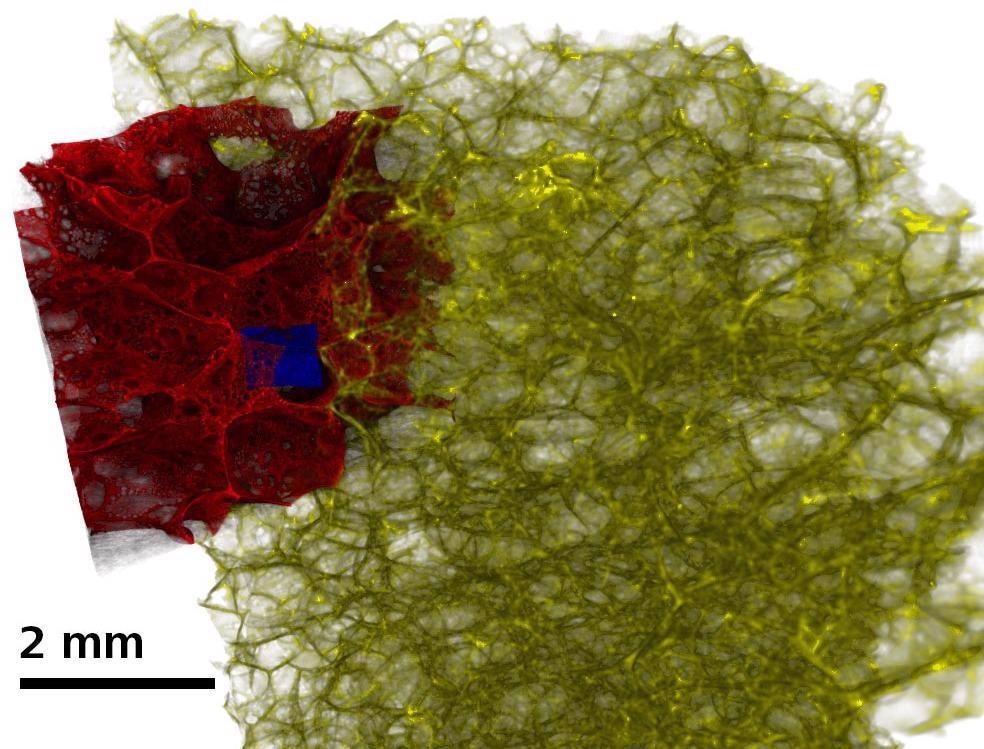

Additive manufactured lattice structure. Image Credit: Carl Zeiss Raw Materials

Porous glass foam insulation imaged at multiple length scales. Image Credit: Carl Zeiss Raw Materials

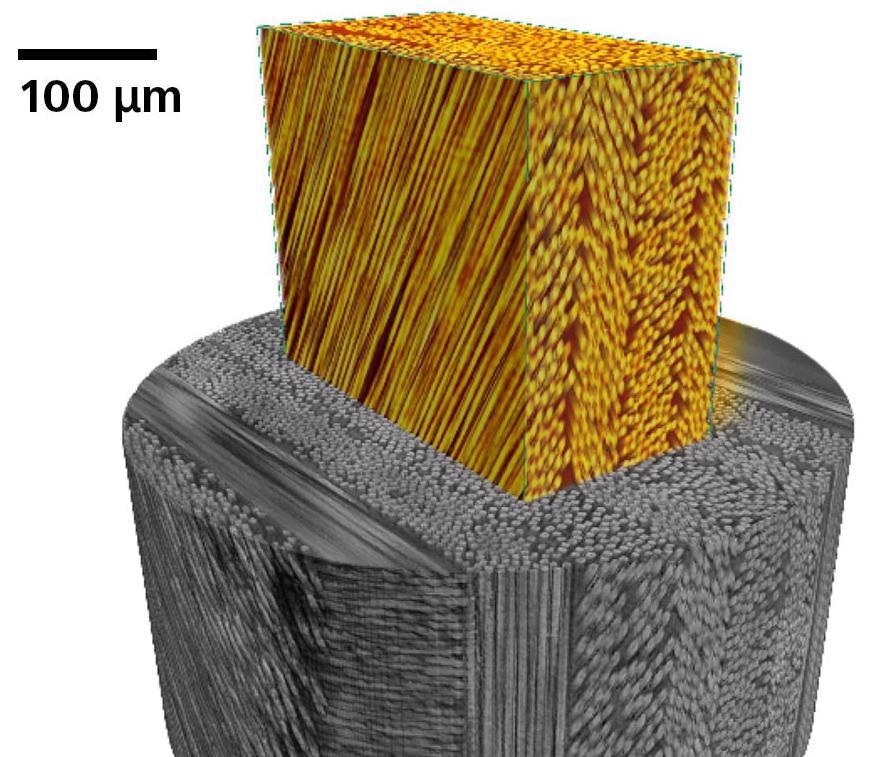

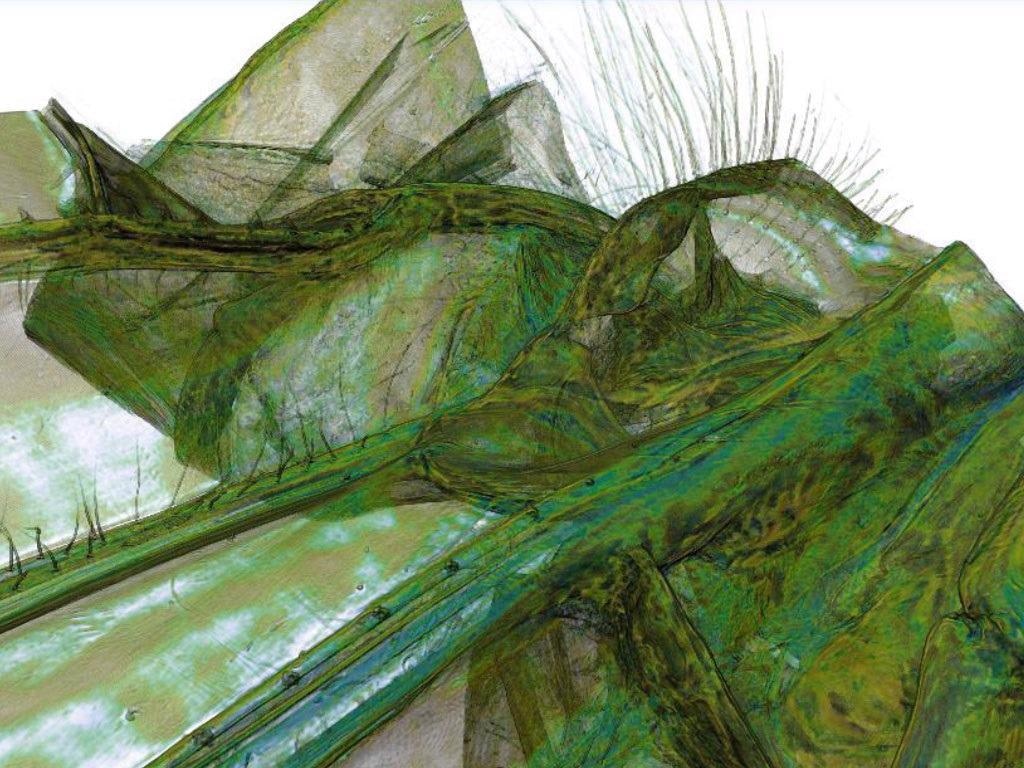

Carbon fiber reinforced polymer composite. Image Credit: Carl Zeiss Raw Materials

Localized high resolution tomography and segmentation of multiple phases in concrete. Image Credit: Carl Zeiss Raw Materials

Raw Materials

Typical Tasks and Applications

- Users can study the grain alignments of steel and other metals

- Particle analysis with complete three-dimensional reconstruction

- Examine pore structure and fluid flow at numerous scales

- Using LabDCT Pro, observe crystal formations

- Using in situ flow technology, openly monitor fluid flow at the pore scale

- Enhance mining processes by analyzing tailings to maximize mining efforts, performing thermodynamic leaching studies, and performing QA/QC analysis on mining products like iron ore pellets

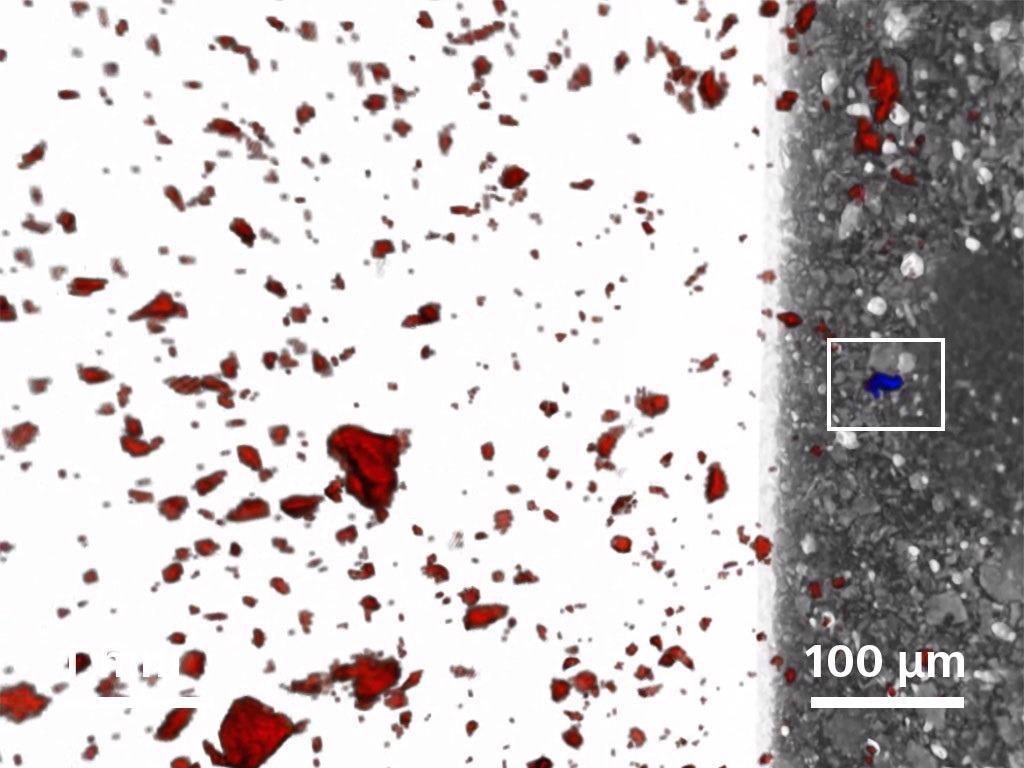

Individual gold grain identified from a population of ~26,000 pyrite grains. Image Credit: Carl Zeiss Raw Materials

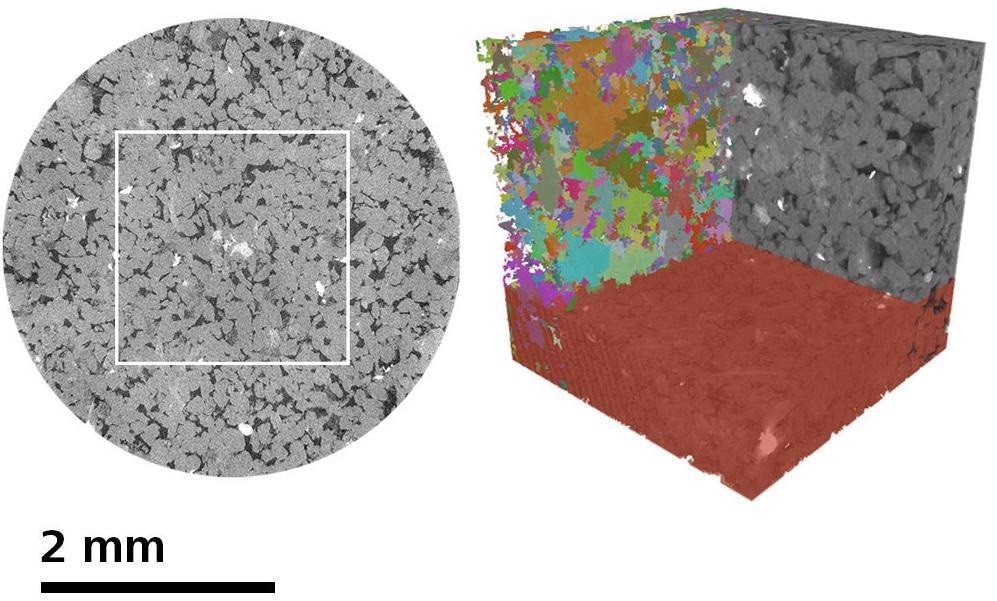

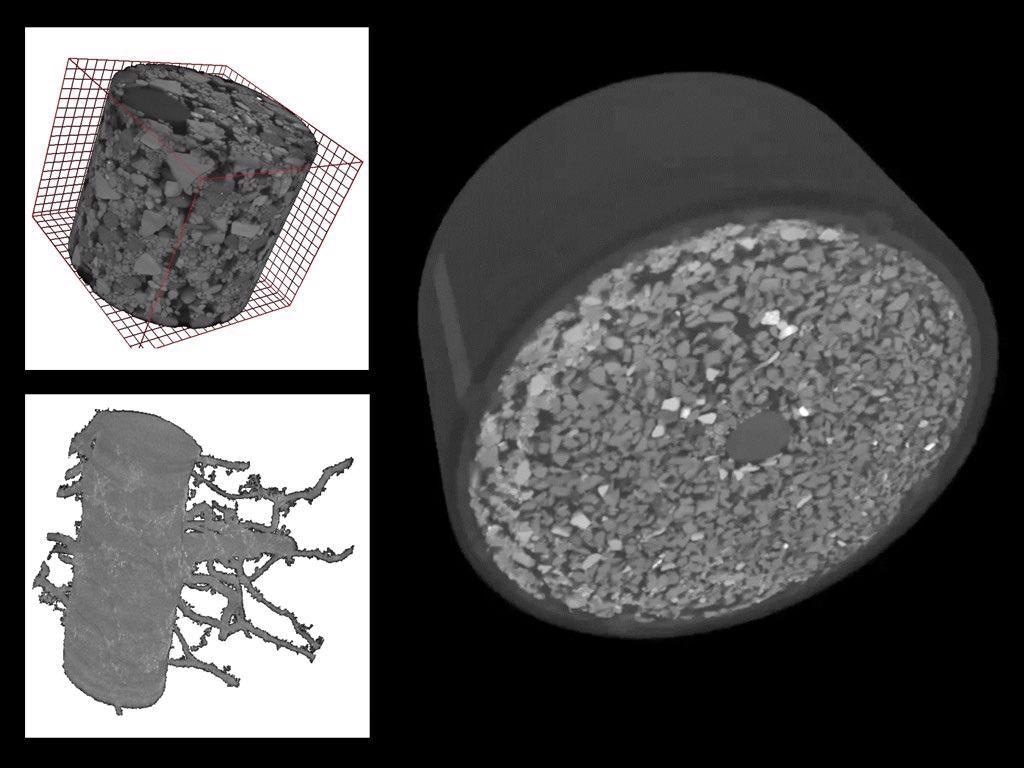

Multiscale non-invasive characterization of sandstone core, showing high quality non-invasive interior tomography and integrated pore scale analytical investigation (showing pore separation). Image Credit: Carl Zeiss Raw Materials

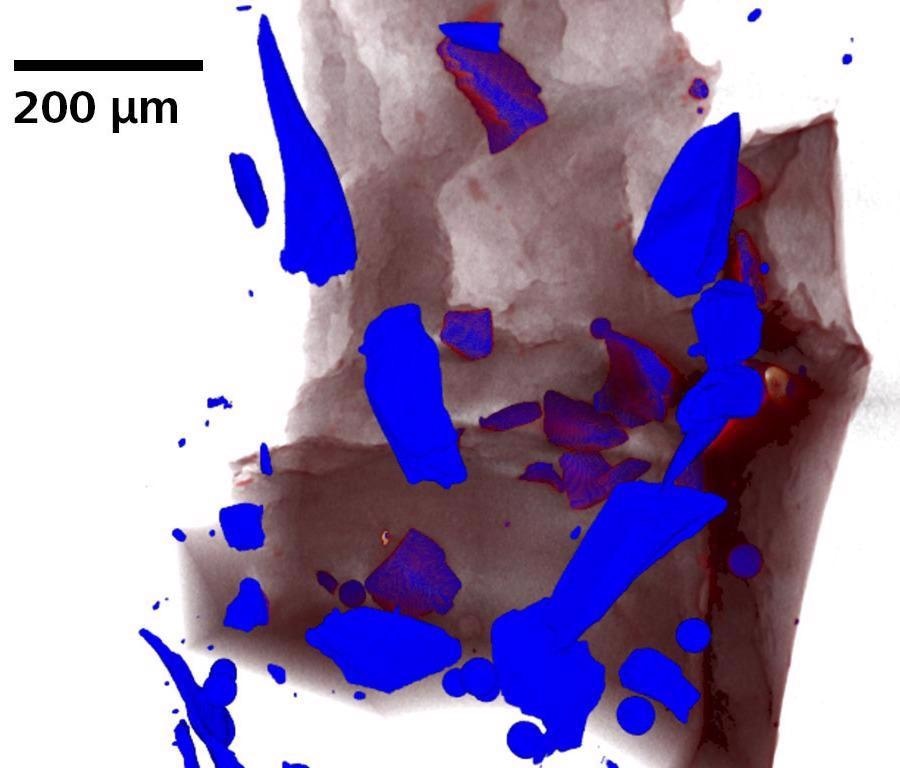

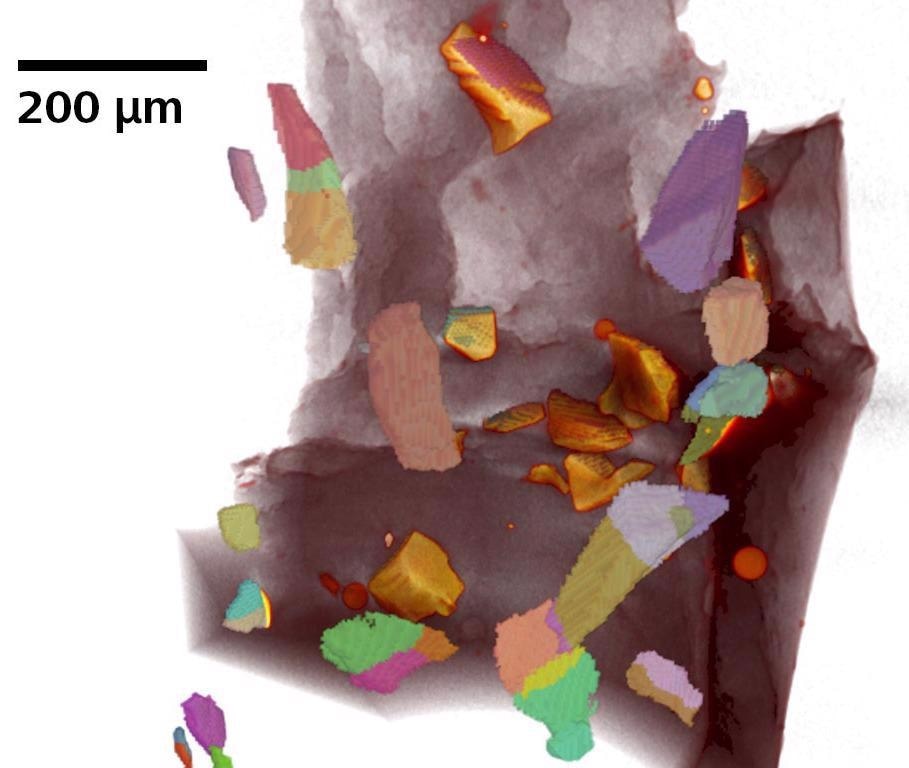

Traditional absorption contrast image of disaggregated olivine. Image Credit: Carl Zeiss Raw Materials

Individual sub-crystals identified using LabDCT Pro on disaggregated olivine. Image Credit: Carl Zeiss Raw Materials

Life Sciences

Typical Tasks and Applications

- Imaging of delicate animals and plants without sample preparation or sectioning

- 3D imaging of biological samples in their natural setting

- Sub-micron photography of solid things, like seeds in their entirety

- Without any distinct sample preparation, imaging of plant roots that are still rooted in their native soil

The XRM micrograph of a blossom reveals its components in a new 3D view. Sepals (yellow) and petals (purple) can be distinguished. Image Credit: Carl Zeiss Raw Materials

Dragonfly imaged in its native structure without any sample preparation and sectioning. Image Credit: Carl Zeiss Raw Materials

Seeds are very solid and compact structures and their inside is difficult to image as a whole. The image shows the pre-shaped seed leaves which will contain the energy reservoir for the further grow of the plant. Image Credit: Carl Zeiss Raw Materials

Embedded plant root in soil: the root can be recognized as a dominant structure within the soil which consists of grains of different sizes and shapes. Voxel size: 5.5 µm. Image Credit: Carl Zeiss Raw Materials

Technology Insights

Non-destructive imaging with best-in-class resolution and contrast.

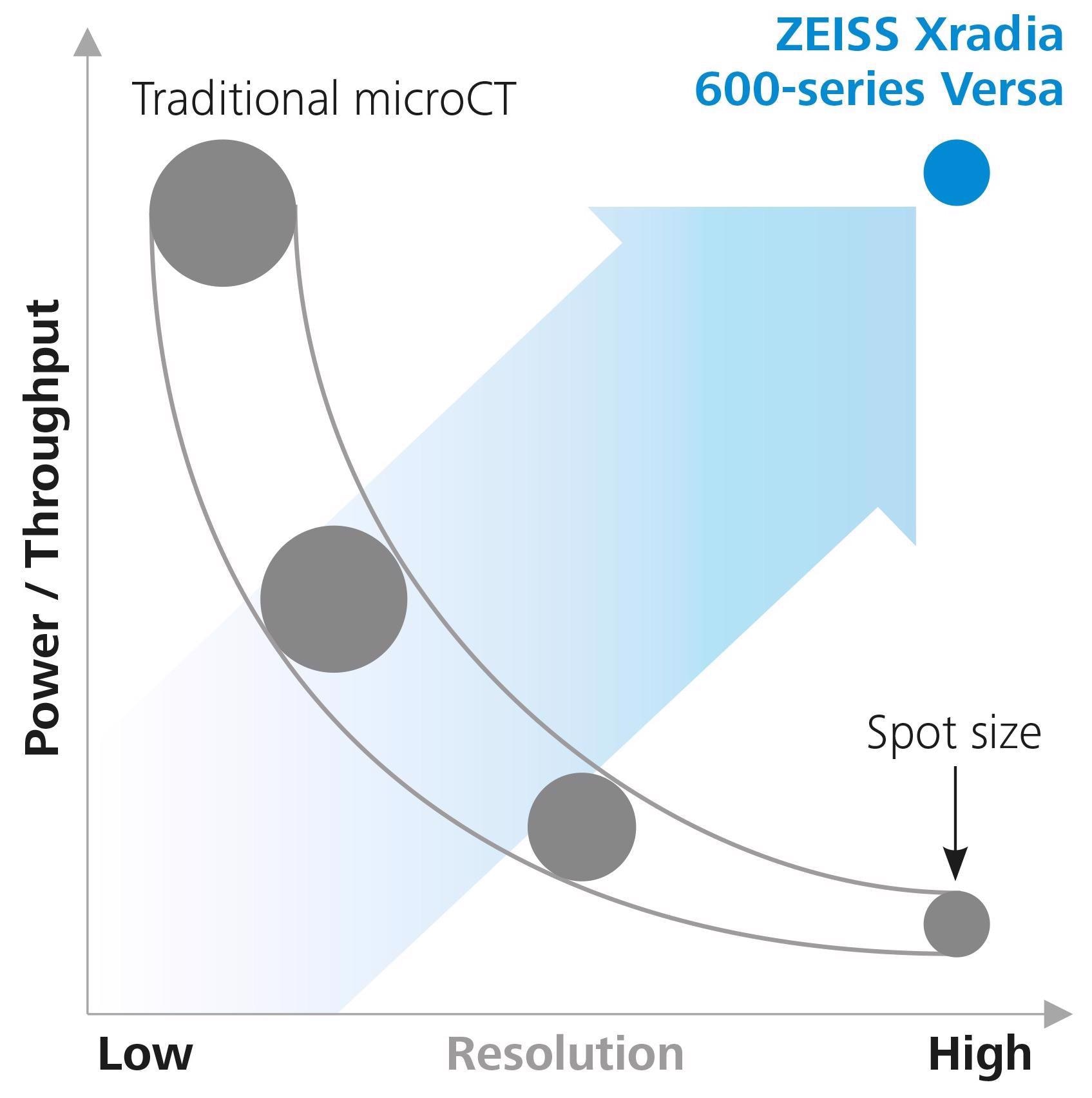

Highest Resolution without Compromise

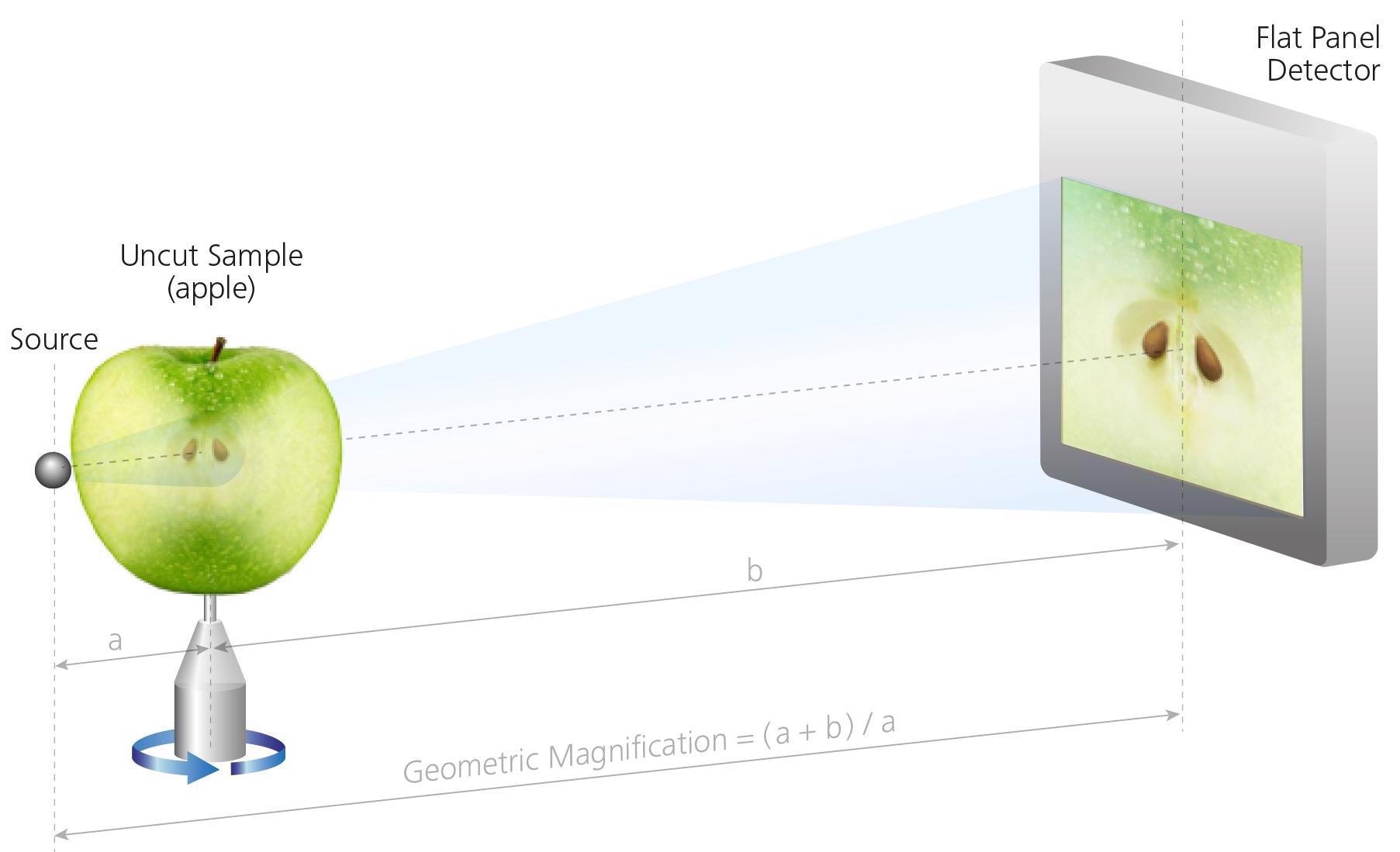

Standard X-Ray computed tomography (CT) is limited to small sample sizes when imaging at high resolution due to the geometric nature of magnification. Maintaining high resolution for larger samples is difficult due to the required long working distances.

Sustaining high resolution for big samples is hard as a result of the extended working distances that are required. This limits the practical application of the maximum resolution advertised by most CT manufacturers.

ZEISS Versa’s Xradia 600 Series addresses these trade-offs by merging dual-stage magnification with high flux X-Ray source technology.

ZEISS specifies a true spatial resolution, providing a unified measure of microscope effectiveness for 3D X-Ray measurement. Spatial resolution refers to the smallest separation between two characteristics that an imaging system can correct. ZEISS Xradia 600 Series Versa systems with a minimum voxel size of 40 nm are able to achieve a spatial resolution of 500 nm.

Image Credit: Carl Zeiss Raw Materials

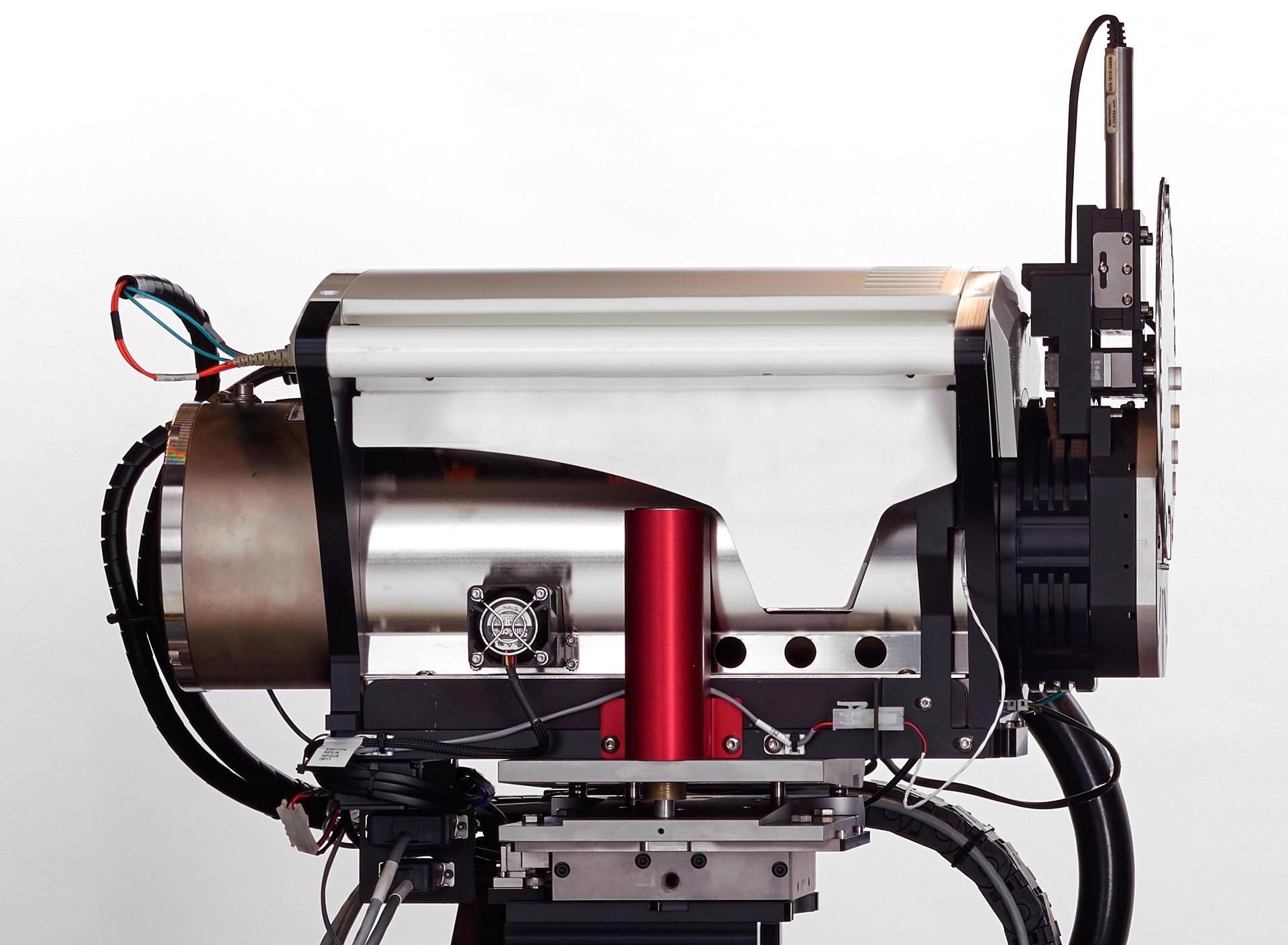

Higher X-Ray Flux Source

Numerous Advantages

The ZEISS Xradia 600 Series Versa has a revolutionary high power (25 W) X-Ray source technology that provides significantly more X-Ray flux than its predecessors do.

The potential source pushes the limits of effectiveness with improved thermal management, increased flux and throughput, and resolution efficiency. A new source management system improves source responsiveness, resulting in faster scan configuration and a more pleasurable user experience.

What an advanced X-Ray flux provides:

- Multiple sample runs

- More pronounced diffraction patterns

- Long/multi-scan workflows are now possible (in situ, DSCoVer, stitching, DCT)

- Quicker tomography scans

- Improved contrast-to-noise ratio

- Large areas of interest

ZEISS Xradia 620 Versa X-Ray source. Image Credit: Carl Zeiss Raw Materials

ZEISS X-Ray Microscopes

The Versatile Advantage of RaaD

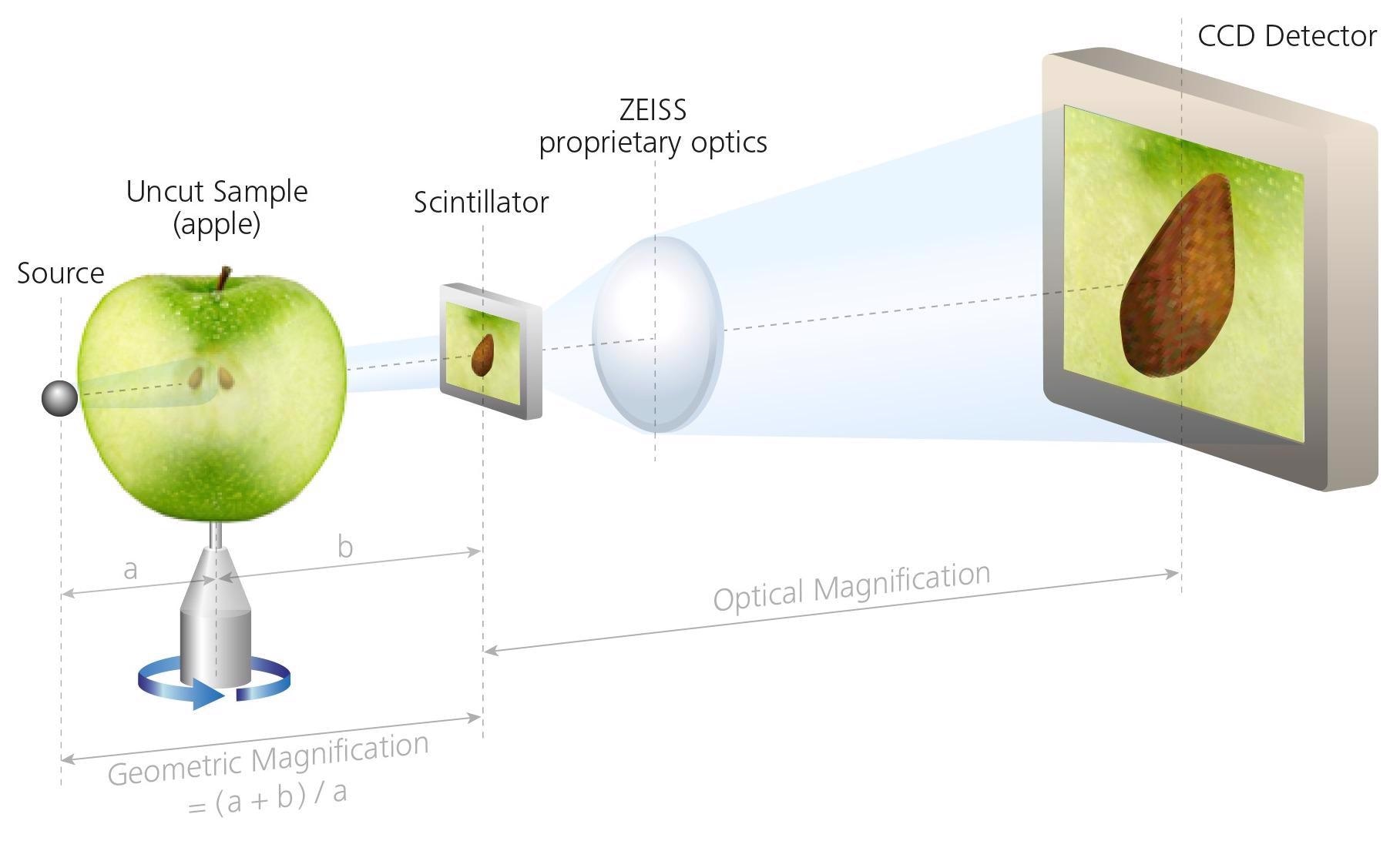

The ZEISS Xradia Versa has a two-stage magnification design that allows for sub-micron resolution imaging at long working distances (Resolution at a Distance) for a variety of sample sizes and types.

Pictures are first geometrically magnified, as in conventional microCT, and then set onto a scintillator, transforming X-Rays into visible range images, which are then optically magnified using microscope optics before being obtained by a CCD detector.

With more X-Ray photons available, the ZEISS Xradia 600 Series Versa provides quick results for a wider range of sample sizes and types without compromising on resolution.

Image Credit: Carl Zeiss Raw Materials

Conventional microCT Architecture

Sample must be close to the source to achieve resolution. Image Credit: Carl Zeiss Raw Materials

ZEISS XRM Two-stage Magnification Architecture

Sample imaged independently of distance to the source, enabling interiors of larger samples to be imaged non-destructively at higher resolution. Image Credit: Carl Zeiss Raw Materials

Accessories

Extend the range of possibilities for advanced material characterization in 3D.

ZEISS Advanced Reconstruction Toolbox

Improved image quality, and higher throughput.

Image Credit: Carl Zeiss Raw Materials

Artificial Intelligence (AI)-driven reconstruction methods are introduced by Advanced Reconstruction Toolbox (ART) on the ZEISS Xradia 3D X-Ray microscope (XRM) or microCT. With a better understanding of both X-Ray physics and applications, users can approach some of the most difficult imaging problems in novel and innovative ways.

Users can explore how OptiRecon and DeepRecon variants, as well as PhaseEvolve, ART’s proprietary modules, enhance data acquisition, reconstruction speed, and image quality without sacrificing resolution.

The user can employ the Advanced Reconstruction Toolbox to:

- Enhanced contrast-to-noise ratio reveals tiny differences

- Achieve superior interior tomography or throughput on a wide range of samples

- Increase the speed of sample classes that require repetitive workflow by an order of magnitude

- Enhance data collecting and analysis for more accurate and timely decision-making

- Improve image quality

The optional modules are workstation-based solutions for easy accessibility and usability:

- PhaseEvolve for contrast improvement

- OptiRecon for iterative reconstruction

- DeepRecon Pro & Custom for Deep learning-based reconstruction

Image Credit: Carl Zeiss Raw Materials

ZEISS DeepRecon Pro provides a straightforward, uncomplicated, and powerful application of AI and deep neural network technology for enhancing X-Ray tomography results without prior knowledge of deep learning technology. [...] It helps us to reduce the scan time required for in situ fluid-rock interaction experiments when we need to work with long exposure times.

Dr. Markus Ohl, X-Ray microscopy, EPOS-NL MINT, Utrecht University, NL

LabDCT Pro

Unlocking Crystallographic Information

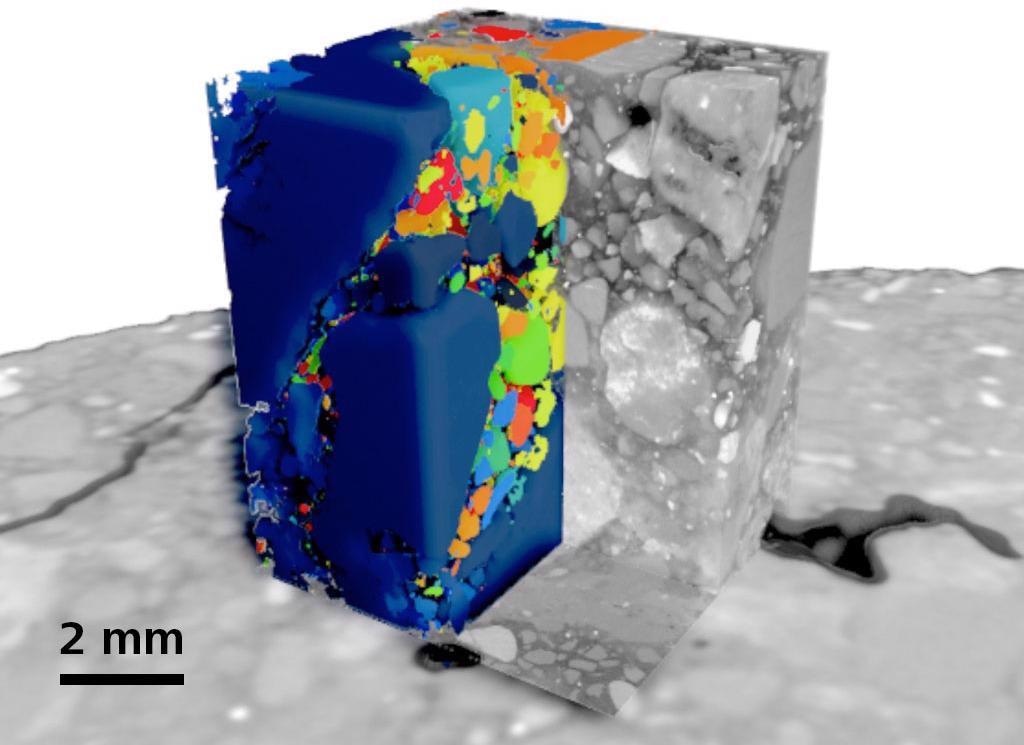

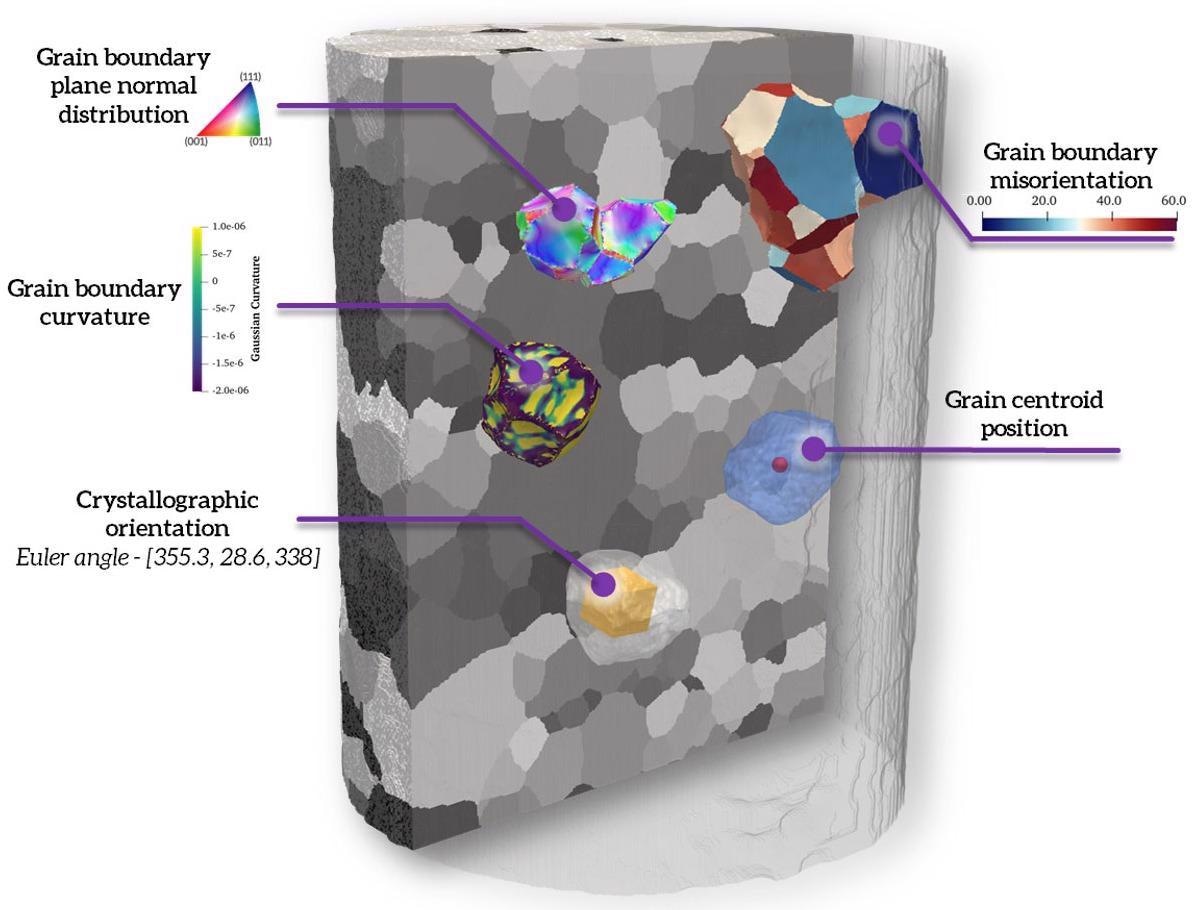

Non-destructive 3D imaging of grain alignment and microstructure is possible with LabDCT Pro for diffraction contrast tomography (DCT), which is only available on the Xradia 620 Versa. The ability to accurately visualize 3D crystallographic grain orientation adds a new level to the characterization of polycrystalline materials like metal alloys, geomaterials, ceramics, and medicines.

- To comprehend structure-property interactions, combine modalities

- Experimentation with 4D imaging to study microstructural evolution

- Combine 3D crystallographic data with 3D microstructural information

- LabDCT Pro enables specimens with crystal structures ranging from cubic symmetry to lower symmetry systems, such as monoclinic materials

- Obtain detailed 3D microstructure analysis from greater representative volumes and a variety of sample shapes

- Using the dedicated 4X DCT objective, collect high-resolution crystallographic data. Use large area mapping for even larger samples and the Flat Panel Extension to boost throughput (FPX)

Non-destructive three-dimensional grain map of an Armco iron sample with illustrations of the various grain analysis that can be performed on a typical LabDCT Pro dataset. Image Credit: Carl Zeiss Raw Materials

Flat Panel Extension

With High Throughput, Image Significantly Larger Samples

The optional Flat Panel Extension (FPX) enables large-sample, high-throughput scanning with the highest image quality from ZEISS. FPX enhances imaging versatility and workflow efficiencies with a fully-featured solution for industrial and academic investigation.

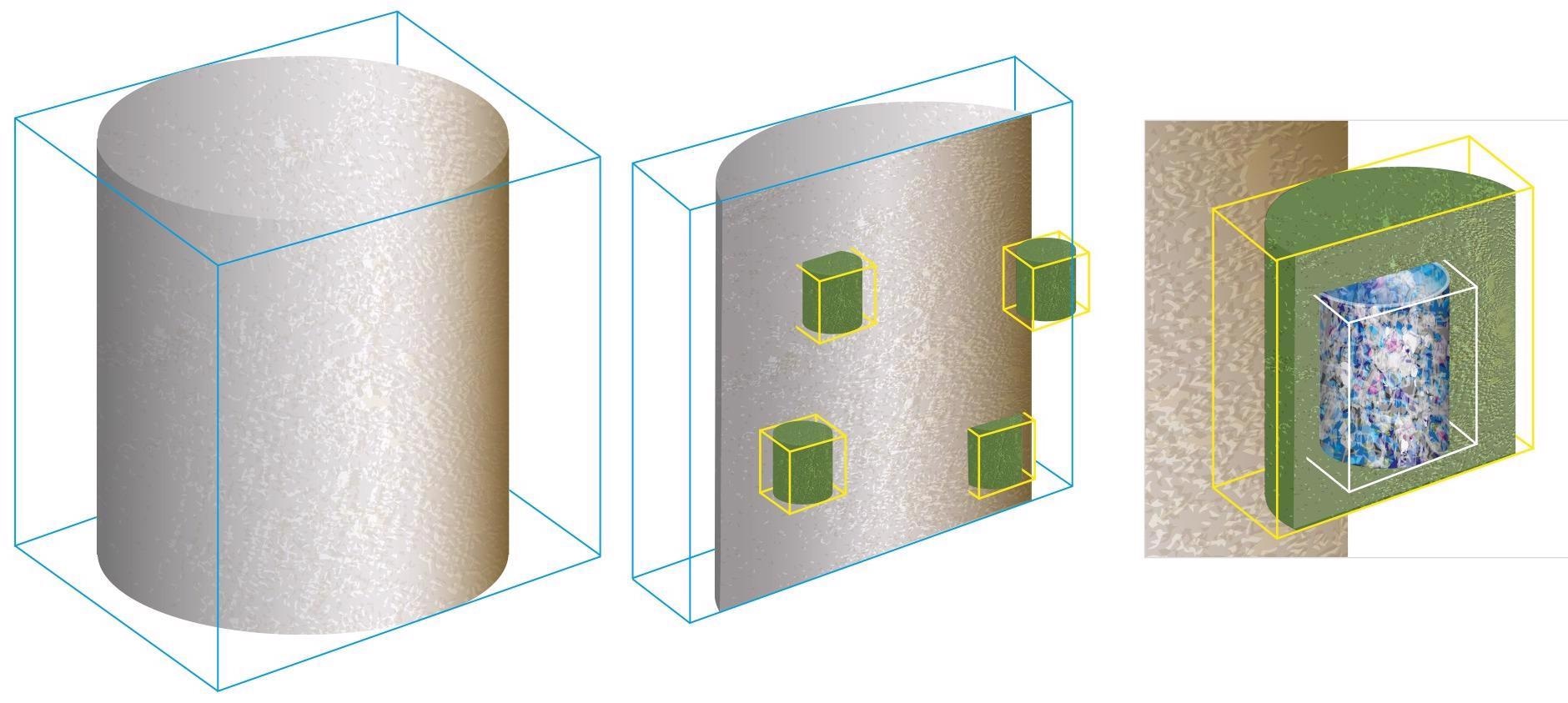

Scout-and-Zoom is a ZEISS X-Ray microscope capability that utilizes FPX to perform exploratory “Scout” scans over a greater range to identify interior objects of interest for higher resolution “Zoom” scans without the need for complex sample processing.

FPX also has the high throughput and large area mapping capabilities of the LabDCT Pro.

Three-stage Scout-and-Zoom workflow. Image Credit: Carl Zeiss Raw Materials

in situ Experiments

Push the Limits for Scientific Development

The ZEISS Xradia X-Ray system is an industry-leading 3D imaging solution for a broad range of in situ rigs, such as high-pressure flow cells, strain, pressure, and heat stages.

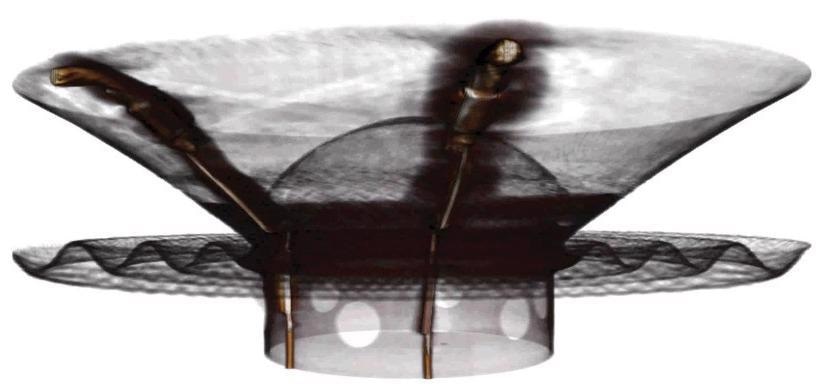

Broadening research beyond the three dimensions of space, 4D experiments use the non-destructive nature of X-Ray analysis to enlarge studies into the dimension of time. The ZEISS Xradia XRM platforms are capable of providing a broad range of in situ rigs, such as highly pressurized flow cells, tension, compression, and temperature phases, and user-customized designs.

The ZEISS Xradia XRM can be upgraded with an optional in situ Interface Kit, which includes a robotic integration package, a powerful wiring guide and other facilities (feed-throughs), and recipe-based software that provides easy operation from within the Scout-and-Scan user interface.

Transform the ZEISS Xradia XRM to an Xradia 620 Versa X-Ray microscope to reap the benefits of Resolution at a Distance (RaaD) technology for the greatest efficiency tomographic imaging of samples within in situ chambers or rigs when the resolution limits of in situ studies have to be pushed.

Tensile testing of laser welded steel under increasing load. Image Credit: Carl Zeiss Raw Materials

SmartShield

Protect the Sample Easily to Optimize Experiment Setup

SmartShield is a solution that protects both the sample and the microscope. This collision avoidance system works in tandem with the Scout and Scan Control System. It enables more confident management of Xradia Versa than ever before. With the press of a button, SmartShield creates a digital protective coating based on the dimensions of the sample.

SmartShield offers the following benefits:

- Unmatched scan clarity

- Keeping significant samples and investments safe

- Better operator efficacy is made possible by an easy sample setup

- Upgraded user experience for both novice and experienced users

Metrology Extension

Increasing the Accuracy of Measurement in X-Ray Microscopy

The Metrology Extension (MTX) converts the Xradia 620 Versa into a certified measurement accuracy solution that surpasses the constraints of standard CT technology. This is crucial for industrial and academic laboratories, where component downsizing and incorporation are increasingly driving the demand for high-resolution metrology. It is better to use high-resolution X-Ray imaging in conjunction with precise metrology.

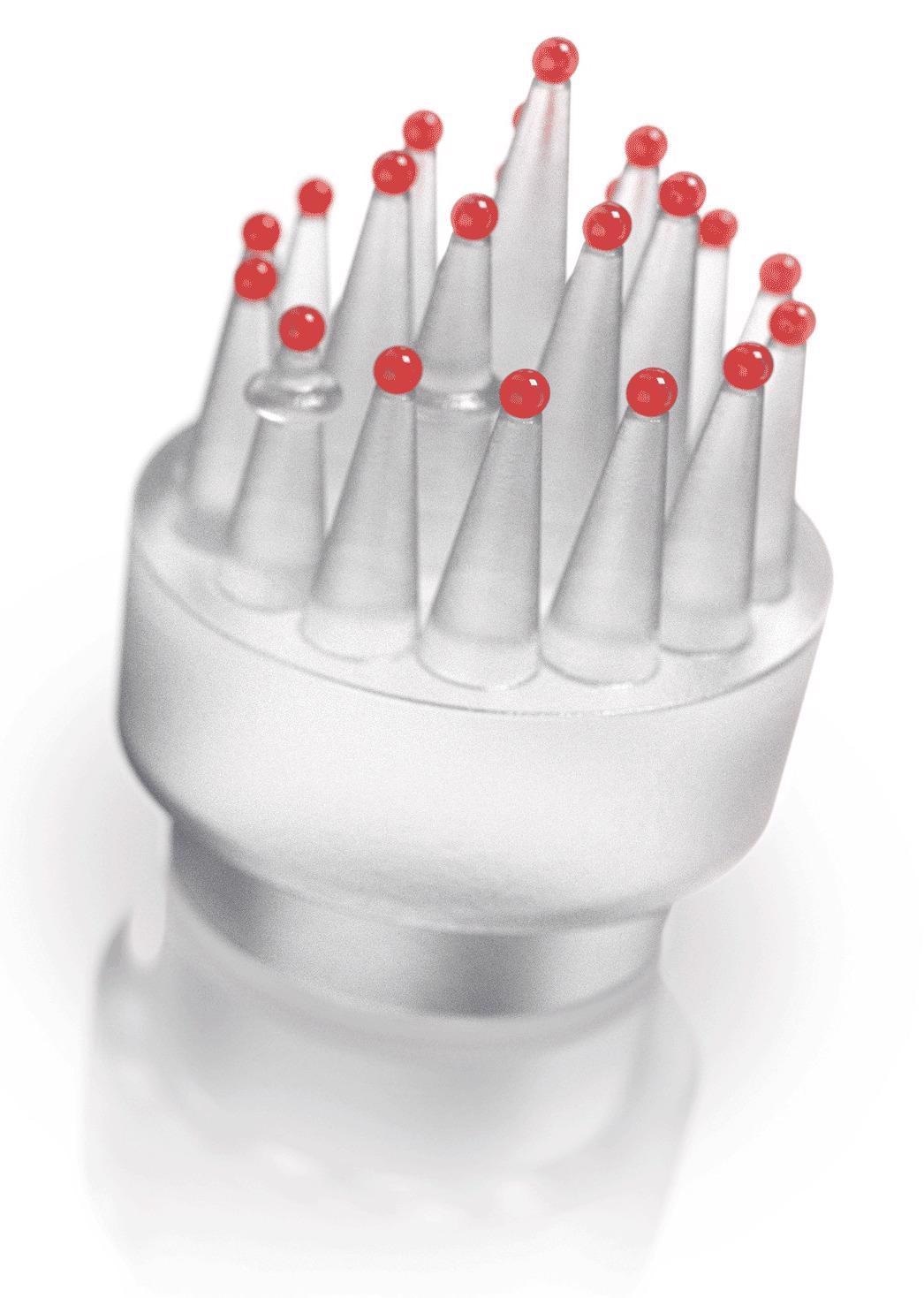

XRM Check: ZEISS has developed a (multi-sphere) length standard for verifying the accuracy of the CT measurements of small-scale dimensions. Image Credit: Carl Zeiss Raw Materials

Reveal Smallest Dimensions

Measure them accurately

- Following the execution of the calibration routine, the user performs precise measurements and makes the results available to standard metrology software for further processing.

- Calibration workflow is simple: The MTX package includes an integrated user-guided calibration workflow.

- Compact volumes, high resolution: MTX enables high-dimensional accuracy measurements within 125 mm3 reconstructed volumes.

- Leading CT metrology precision: When calibrated with MTX, the ZEISS Xradia Versa has a market-leading maximum permitted error value of MPESD = (1.9 + L/100) μm for measurements in small-scale volumes, where L is the measured length in millimeters.

Non-contact, non-destructive measurement of a smartphone camera lens module. Image Credit: Carl Zeiss Raw Materials

Autoloader

Improve the Efficiency of Sample Handling

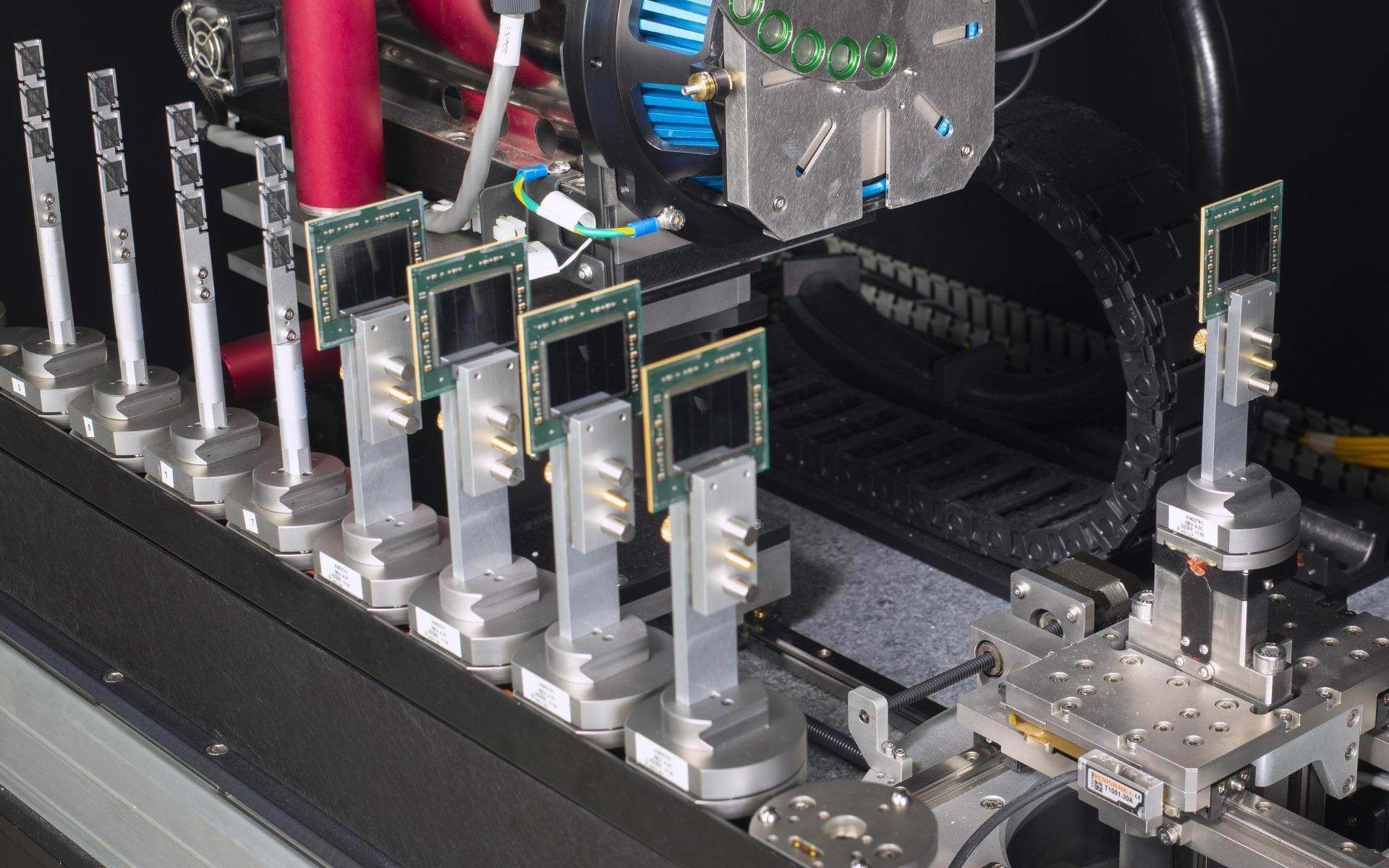

Autoloader option enables to program up to 70 samples at a time to run sequentially. Image Credit: Carl Zeiss Raw Materials

Boost the instrument’s usability with the optional Autoloader, which is available for all ZEISS Xradia X-Ray microscope platforms.

Users can reduce the frequency of involvement while increasing efficiency by queueing multiple jobs. They can load up to 14 sample stations, each with a capacity of 70 samples, and schedule them to run overnight or over several days.

Mechanical stability previously unseen in the industry enables high volume quantitative recurring scanning of similar samples.

Wide Field Mode

Image Larger Samples with Greater Flexibility

Image large samples with Wide Field Mode such as this 6” stereo speaker. Image Credit: Carl Zeiss Raw Materials

To snap photos with a strong lateral visual field, users must use Wide Field Mode (WFM). The wide lateral field of view can provide a 3× larger 3D volume or greater voxel density than a basic field of view for large samples.

All Xradia Versa systems support WFM with the 0.4× objective. The Xradia 620 Versa system also includes WFM with a 4× objective. When combined with Vertical Stitching, WFM enables users to photograph bigger samples in great quality.

Automated Filter Changer

Simplify the Examination of Difficult Samples

The Automated Filter Changer (AFC) offers 12 standard filters with room for 12 custom filters. Image Credit: Carl Zeiss Raw Materials

To improve contrast, X-Ray source attenuation filters are used to regulate the X-Ray energy spectrum highlighting the sample, which is reliant on the sample’s distinctive material properties. Every ZEISS Xradia Versa comes standard with a set of 12 filters.

For manual filter shifting, the ZEISS Xradia 610 Versa has a single filter slot. The ZEISS Xradia 620 Versa systems’ Automated Filter Changer (AFC) promotes ease of use by providing seamless filter modifications for the suitable investigation of unknown materials.

The Xradia 600 Series Versa

Source: Carl Zeiss Raw Materials

| |

ZEISS Xradia 610 Versa |

ZEISS Xradia 620 Versa |

| Spatial resolutiona |

500 nm |

500 nm |

Resolution at a Distance (RaaD™)a,b

(at 50 mm working distance) |

1.0 μm |

1.0 μm |

Minimum Achievable Voxelc

(Voxel size at sample at maximum magnification) |

40 nm |

40 nm |

| Source Voltage Range |

30–160 kV |

30–160 kV |

| Source Maximum Power Output |

25 W |

25 W |

| Scout-and-Scan™ Control System |

✓ |

✓ |

| Scout-and-Zoom |

✓ |

✓ |

| ZEISS OptiRecon |

Optional |

Optional |

| ZEISS DeepRecon |

Optional |

Optional |

| SmartShield |

✓ |

✓ |

| Vertical Stitch |

✓ |

✓ |

| XRM Python API |

✓ |

✓ |

| Automated Filter Changer (AFC) |

|

✓ |

| High Aspect Ratio Tomography (HART) |

|

✓ |

| Dual Scan Contrast Visualizer (DSCoVer) |

|

✓ |

| Wide Field Mode |

0.4x |

0.4x and 4x |

| ZEISS LabDCT Pro for Diffraction Contrast Tomography |

|

Optional |

| ZEISS Autoloader |

Optional |

Optional |

| In Situ Interface Kit |

Optional |

Optional |

| ZEISS ZEN Intellesis |

Optional |

Optional |

| ORS Dragonfly Pro |

Optional |

Optional |

| ZEISS Metrology Extension (MTX) |

|

Optional |

aZEISS Xradia 2D resolution target, normal field mode, and optional 40× objective were used to test spatial resolution.

b The RaaDTM working distance is defined as the clearance around the rotating axis.

c Voxel is a geometric word that adds to resolution but does not determine it, and is used solely for comparative purposes.

The genuine overall measurement of instrument resolution, as defined by ZEISS, is spatial resolution.

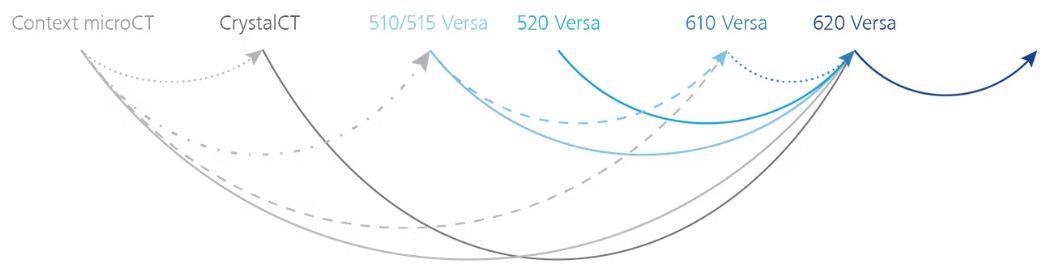

Protect the Investment

ZEISS X-Ray microscopes are intended to be customizable and extendable with future developments and advancements to protect customers’ investments. This guarantees that the capabilities of the microscope improve in tandem with breakthroughs in cutting-edge technology.

Using ZEISS Xradia Context microCT, ZEISS CrystalCT, ZEISS Xradia 510/520 Versa, and now ZEISS Xradia 610/620 Versa, consumers can field-convert their systems to the most recent X-Ray microscopes.

Image Credit: Carl Zeiss Raw Materials

Software

Use the Simple Control System to Create Efficient Workflows

The Scout-and-Scan Control System allows the user to quickly scout a target area and clarify scanning parameters. Utilize the simple system in the central lab, where users may have differing levels of competence.

Users can benefit from the following:

- Micropositioning is possible with a single mouse clicks

- Autoloader option for several samples

- Internal camera for viewing samples

- Recipe management (set, save, recall)

- Various energies

Scout-and-Scan Control System. Image Credit: Carl Zeiss Raw Materials

ZEISS Mineralogic — Automated Mineralogy

Phase identification and textural examination in 2D and 3D can be performed using ZEISS SEM, XRM, and microCT systems.

Image Credit: Carl Zeiss Raw Materials

Visualization and Analysis Software

ZEISS recommends Object Research Systems’ (ORS) Dragonfly Pro, a cutting-edge analysis and visualization software solution for 3D data obtained by various technologies such as X-Ray, SEM, FIB-SEM, and helium ion microscopy.

ORS Dragonfly Pro, which is only available from ZEISS, is a comprehensive, user-friendly, and customizable toolkit for analyzing and visualizing large amounts of 3D grayscale information. It allows for the annotation, navigation, and creation of media files from 3D data, as well as video production. To evaluate the results, image processing, segmentation, and object examination can be performed.

Image Credit: Carl Zeiss Raw Materials