A state-of-the-art particle analysis and categorization tool, the Smart Particle Investigator (SmartPI) transforms scanning electron microscopes into fully functional applications for metal and steel or industrial cleanliness.

SmartPI combines all aspects of elemental analysis (EDS), SEM control, and image processing into a single application.

- Produce repeatable data and industry-standard compliant reports.

- Integrate SmartPI with ZEISS light microscope particle analysis solutions to structure a correlative workflow.

- SmartPI is flexible with ISO 16232 and VDA 19 cleanliness standards.

- Profit from the global ZEISS service and support for the complete system.

- Ability to control both SEM imaging and EDS analysis with one software program.

- Run automated and neglected particle analyses.

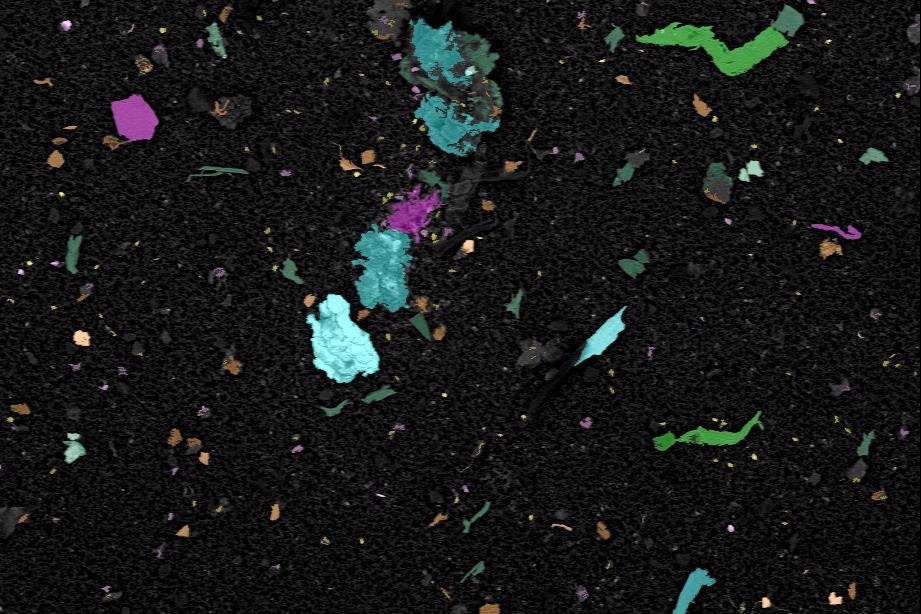

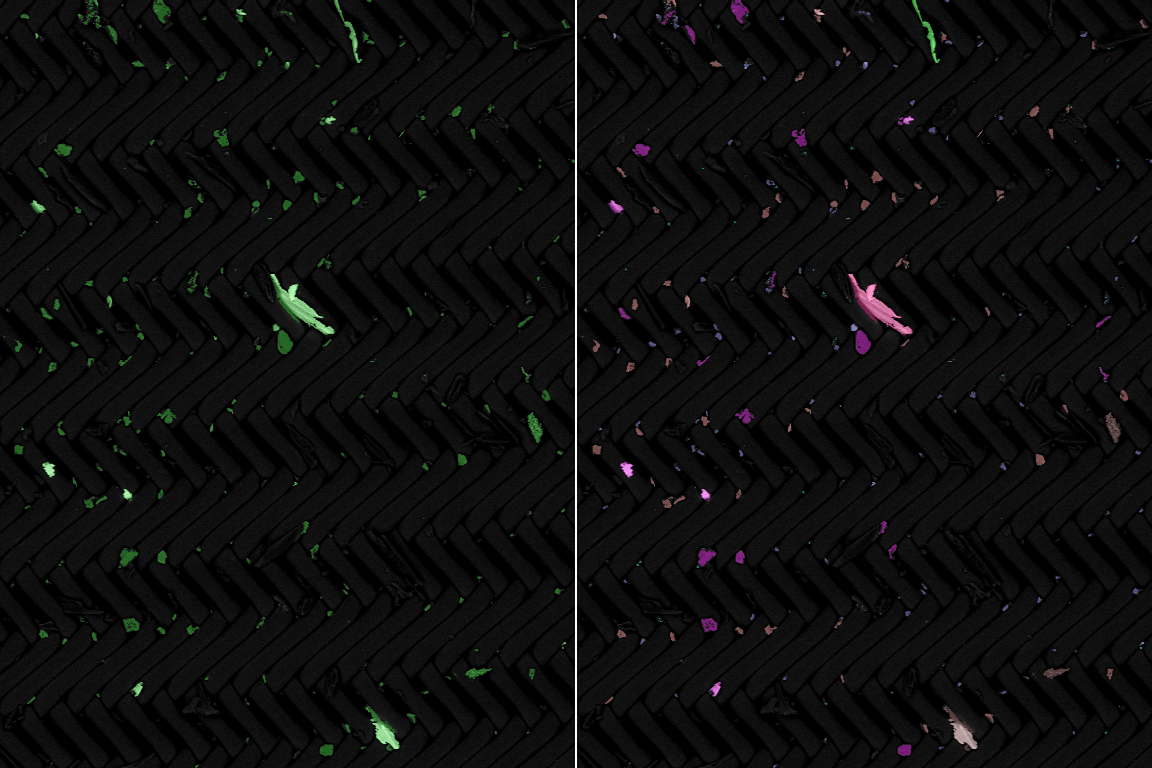

Energy dispersive X-ray (EDS) classification of particles. Image Credit: Carl Zeiss Raw Materials

Advantages

Tailored Precisely to the Needs of Industry

A multinational supplier of automotive parts, which had a special requirement for powerful yet user-friendly particle identification and categorization system, closely collaborated in the development of SmartPI.

This suggests that in addition to taking into account current industrial cleanliness analysis requirements, usability concerns have also been considered for the typical industrial setting, where not every operator is thought of as a microscopy expert and when solutions are dispersed at various locations around the world.

The Power of Simplicity

SmartPI automation greatly simplifies operation; thus, users do not need to be experts in microscopy to get high-quality data. At the same time, highly skilled operators have the ability to quickly create or modify recipes and adapt the analytic algorithms to specific requirements.

For easy data inspection and export, all recipes, system setups, and particle data are kept in an auditable database.

Intelligent Particle Detection

SmartPI is also capable of identifying, describing, and classifying particles that are distributed over several fields of vision, such as truncated particles inside the particle dataset, using an advanced border particle stitching method.

This is particularly important when it comes to ensuring that larger particles are included in the statistics. It is a behavior that could affect the analysis of steel quality or cleanliness.

A Fully Integrated Solution

Users can manage both SEM imaging and EDS analysis with the use of a single software application on a single PC. Data integrity and efficient data recall are both guaranteed by ZEISS SmartPI, which keeps all data together for SEM and EDS.

Additionally, when the EDS system was purchased from an EDS provider, the worldwide ZEISS service and applications team supported the whole SmartPI system, putting all customer care under one roof.

Example Filter. Image Credit: Carl Zeiss Raw Materials

Analysis Start of Tiles. Image Credit: Carl Zeiss Raw Materials

Image Acquisition. Image Credit: Carl Zeiss Raw Materials

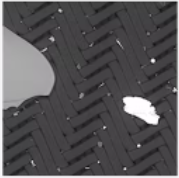

Feature Detection. Image Credit: Carl Zeiss Raw Materials

Automated Segmentation. Image Credit: Carl Zeiss Raw Materials

EDS Classification. Image Credit: Carl Zeiss Raw Materials

Report. Image Credit: Carl Zeiss Raw Materials

SmartPI at Work

Auto-Calibration Procedures

Before and during each auto-run, SmartPI periodically performs auto-calibration and self-diagnostic procedures. This ensures consistency, accuracy, and system stability.

An auto-recovery procedure is started whenever there is a break in the auto-run, such as when a filament change is required.

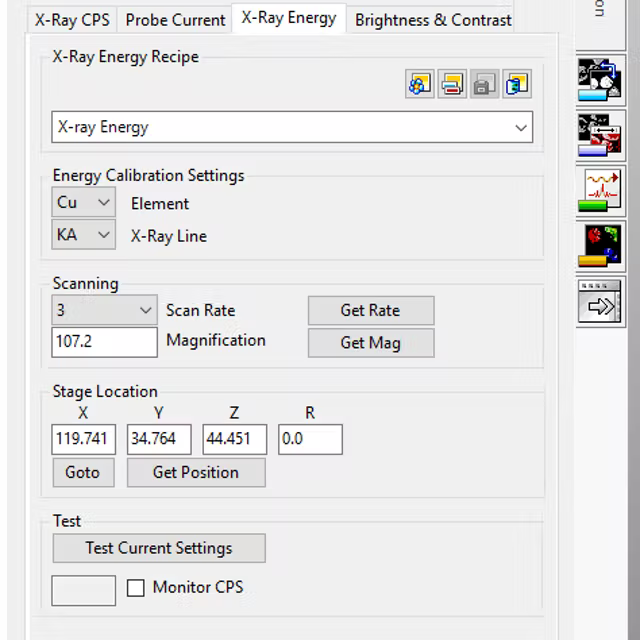

Energy calibration of EDS detector. Image Credit: Carl Zeiss Raw Materials

Morphological and Chemical Classification

For each particle that has been discovered, SmartPI uses cutting-edge image processing and analysis techniques to measure a variety of morphological traits. Later, each particle’s chemical makeup is determined via EDS analysis.

Advanced ZEISS Feature Scan Mode enables users to swiftly study particles in Spot Mode or in more detail. This provides a more accurate categorization by scanning the entire particle form.

Morphological and Chemical Classification. Image Credit: Carl Zeiss Raw Materials

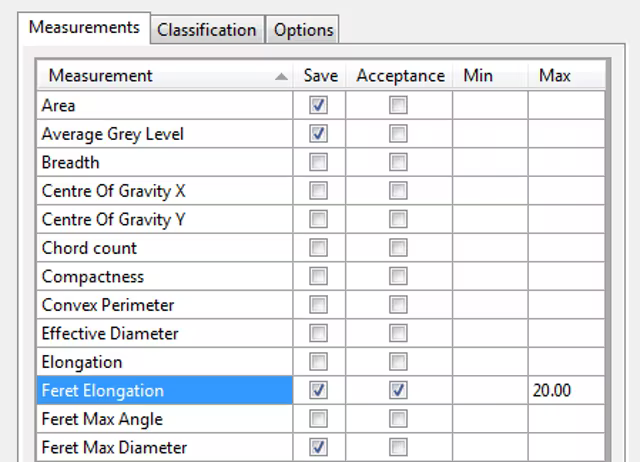

Measurement Exclusions

SmartPI enables customers to exclude particles that are not of interest from further image and elemental analysis, ensuring that users’ particle collections are coherent and shortening runtime.

For instance, this could be the case for extended fibers on the filter that could originate from dust in the surroundings and hence are unconnected to particles that originate from the manufacturing process.

Exclusion of fibers, for example, via limitation of the parameter elongation. Image Credit: Carl Zeiss Raw Materials

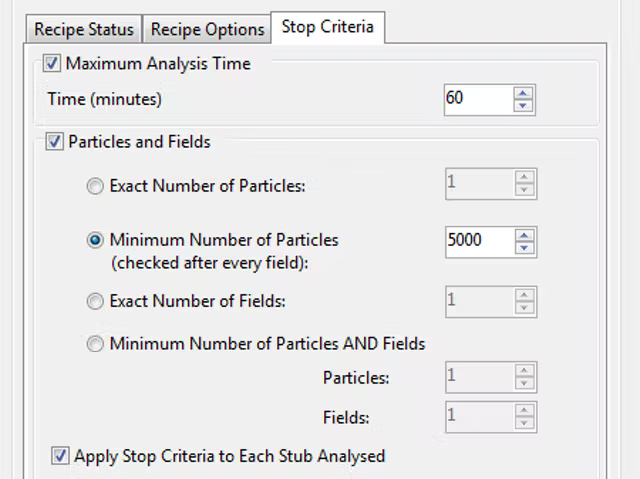

Advanced Stop Criteria

The analysis can be stopped automatically by the auto-run when it reaches a predetermined threshold due to a number of configurable stop criteria. The users’ defined stop criteria can include analysis duration, particle or field counts, a particular category, particle size, or other factors.

This feature can be applied to one or more samples, substantially reducing the overall run-time. The operator can follow the advance and determine whether any intervention is required using the live results pane.

Stop criteria setup page. Image Credit: Carl Zeiss Raw Materials

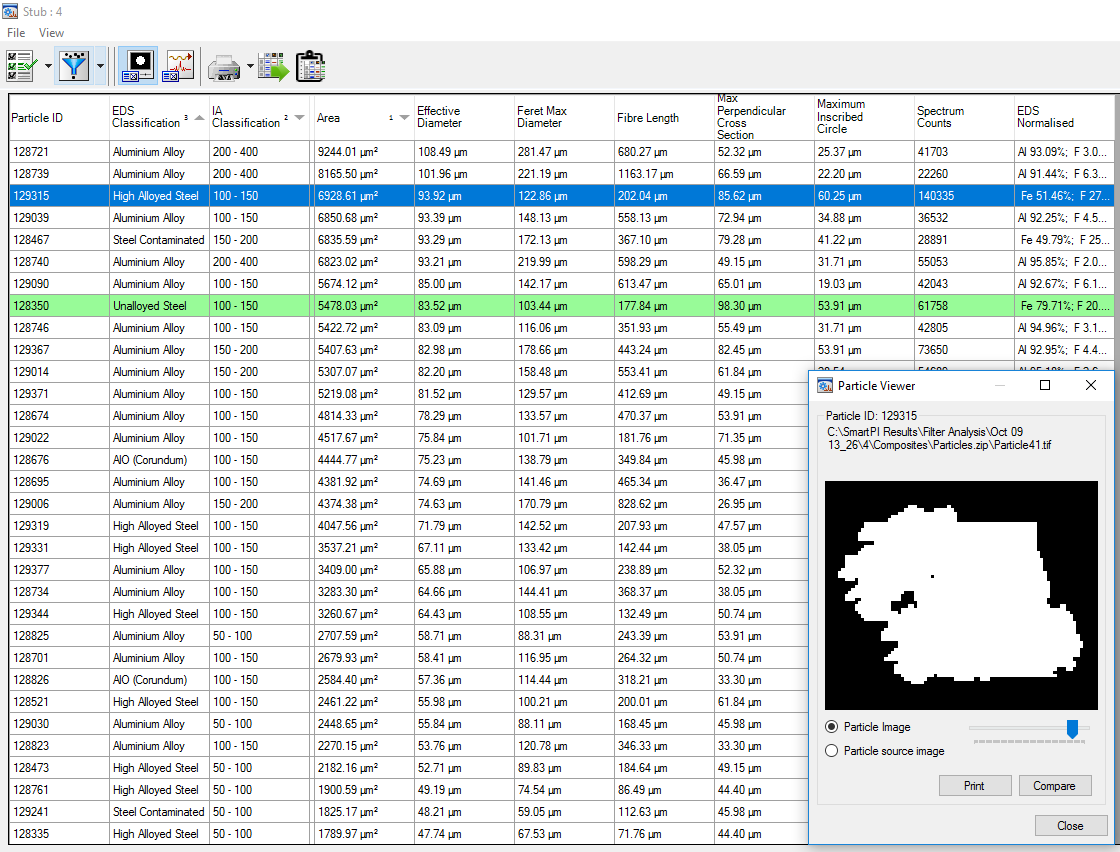

Interactive and Retrospective Particle Classification

By carefully analyzing the results, users can utilize the Review Output mode to improve and refine the categorization recipes. Moreover, users can go back and change any particle by moving the stage to the proper particle coordinates.

With the use of fresh categorization criteria, users can reassess current results in the Retrospective Analysis mode. The sample does not have to be re-analyzed for this.

Use the review mode to re-examine single particles and see all of their properties including EDS composition and material classification. Image Credit: Carl Zeiss Raw Materials

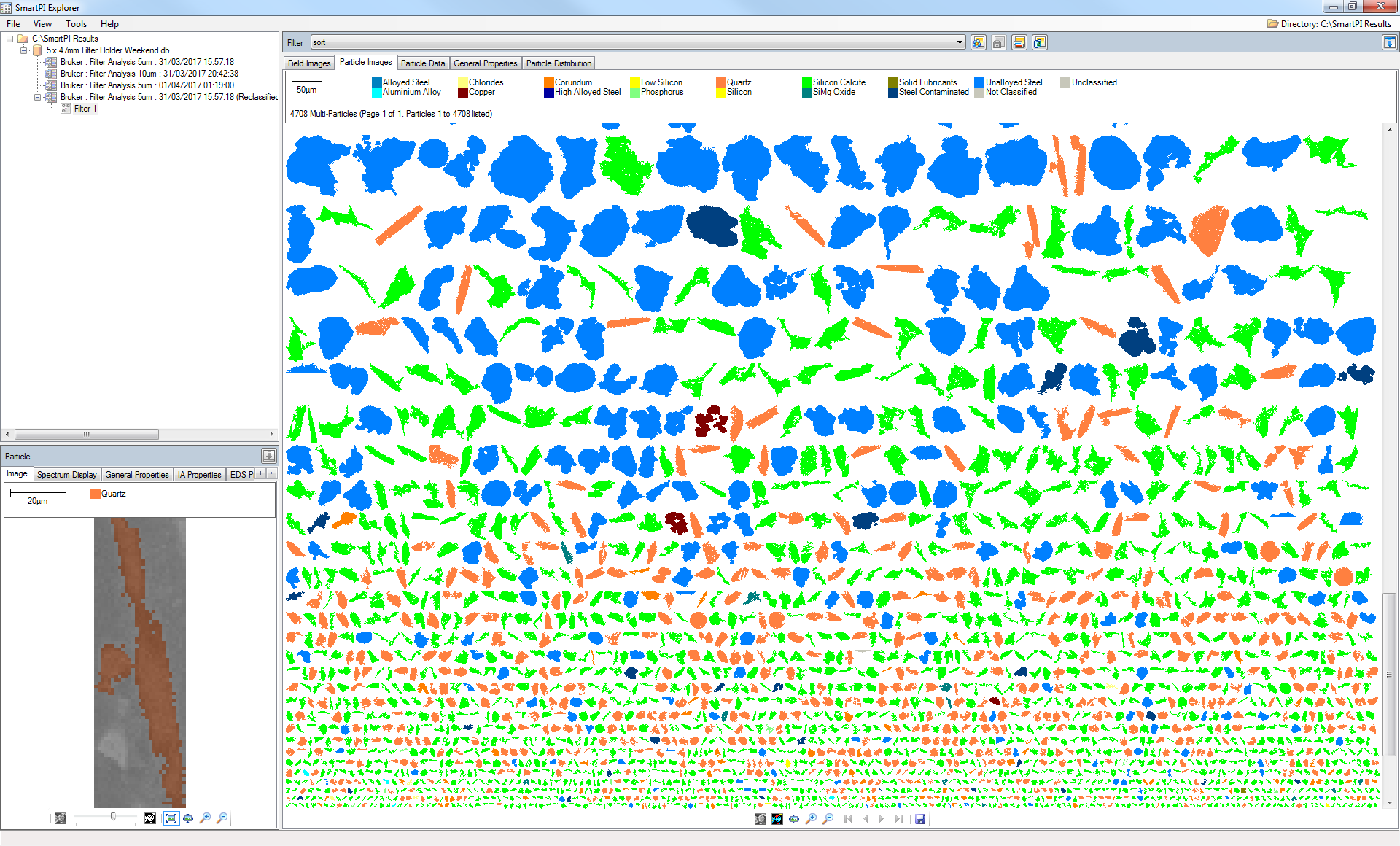

SmartPI Explorer

This standalone application lets the user browse or search the results for individual spectra, particle images, field images, border particles, or other filters that users may select.

In addition, SmartPI Explorer includes options for archiving, as well as an image montage feature for creating a stitched image from the fields analyzed. Explorer can also be used offline to free up system time for analysis.

SmartPI Explorer navigation window with multi-particle view. Image Credit: Carl Zeiss Raw Materials

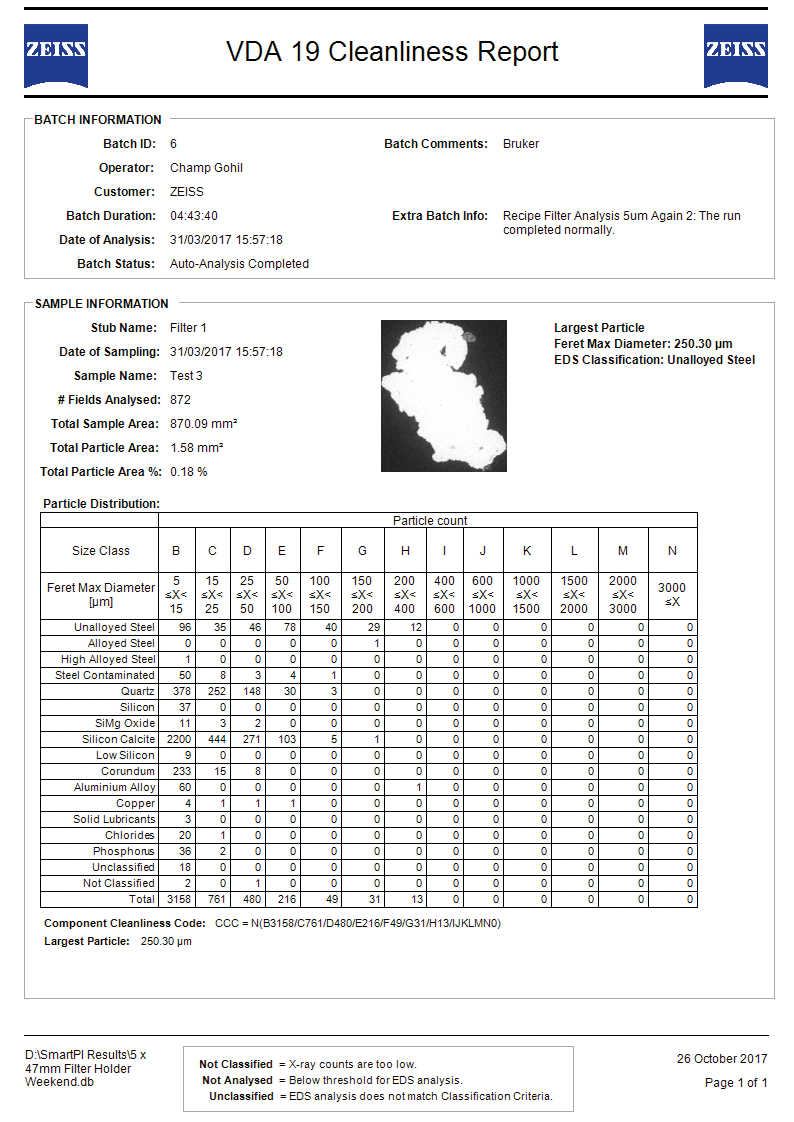

SmartPI Reporter

This standalone program has a number of built-in capabilities that let users create targeted reports. Users have the option of choosing an ISO or VDA standard report, changing the current report template, or using drag-and-drop controls.

As soon as a report has been defined, users can save it as a template for additional reports. Use SmartPI Reporter online for instant report generation or offline for examining the results later on.

VDA 19 cleanliness report generated in SmartPI Reporter. Image Credit: Carl Zeiss Raw Materials

Recommended SEM Platforms

EVO

Scanning Electron Microscope

The traditional SEM of choice for use in routine materials analysis or commercial quality control and failure analysis is EVO. With the help of a sizable motorized 5-axis stage and user-friendly SmartSEM software, EVO offers a highly flexible imaging platform for particle analysis applications.

As EVO has variable pressure (VP), non-conductive materials, such as filters, can be imaged and analyzed without the need for a conductive coating, keeping the filter intact for further examination using, for instance, FTIR or Raman.

Image Credit: Carl Zeiss Raw Materials

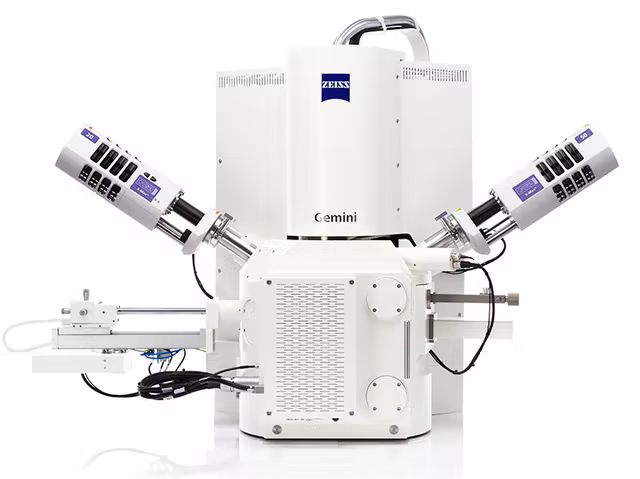

Sigma

Field Emission Scanning Electron Microscope

For users who require improved resolution for particle analysis in the nanometer scale range, Sigma is the SEM of choice. With Gemini column technology, Sigma’s field emission scanning electron microscope (FE-SEM) provides excellent imaging and analytical results.

On a platform that is perfectly suited for elemental analysis, the Gemini optics provide the highest resolution imaging. This is done particularly for magnetic samples.

Image Credit: Carl Zeiss Raw Materials