With a fixed particle counter, the AM II manifold provides sophisticated features for sequentially monitoring aerosol contamination at several locations. When ongoing monitoring is not required, the AM II is perfect for trend analysis and cleanroom verification.

Control Box. Image Credit: Particle Measuring Systems

Manifold Pump. Image Credit: Particle Measuring Systems

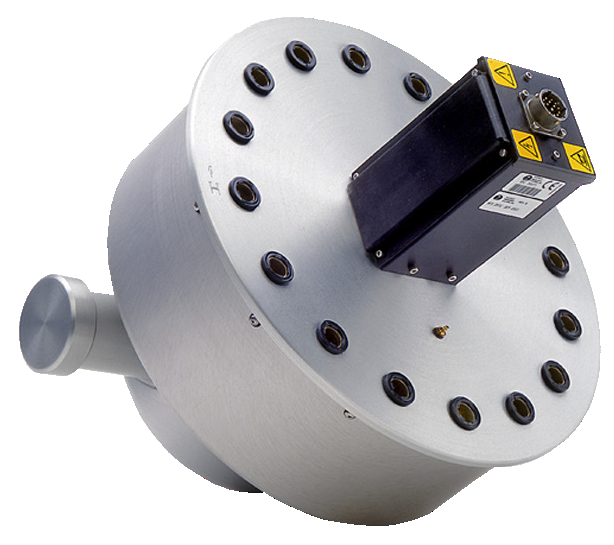

Manifold Module. Image Credit: Particle Measuring Systems

Compatibility

- Lasair® II or Lasair III particle counters, or IsoAir® PLUS particle sensor

Benefits

- Cost Effective

- Cost-effective monitoring of fixed points at timed intervals

- Minimal cost per sample location

- More expansive monitoring area compared to a stationary particle counter

- Communication via Ethernet to the facility monitoring system

- Flexibility

- Programs a sampling routine easily for both simple and complex sequences

- Alters sampling recipe automatically upon receiving an external signal or alarm

- Large coverage area: every sample point can be up to 125 feet away

- Accurate and Rapid Measurements

- Patented flow control ensures that the manifold compensates for manifold pressure drop, removing systematic particle undercounting of up to 15 %

- Reduces gravitational particle settling by maintaining a steady flow (nominal 3 CFM) at each sample point

- Distortion in particle size relationships is prevented using isokinetic sampling probes, which collect particles at the same velocity as sample air

- Features

- Multiplex monitoring of up to 32 sites using a single particle counter

- Managed by the Pharmaceutical Net or Facility Net software

- Programmable recipes and sample point sequences

- Assembly designed to remove contamination from the valves

- Alarm for low vacuum; automatic shut-off for pump overheating

Applications

- Facility monitoring

- Monitoring large mini-environments

- Cleanroom verification and trend analysis

Specifications

Source: Particle Measuring Systems

| Manifold System |

AM II-16 |

AM II-32 |

| Sample ports |

Max. 16, Min. 10 |

Max. 32, Min. 22 |

Operating

range |

Use in locations ISO 8 (Class 100,000) or cleaner

0.1 to 0.3 μm particle counters: Use to simultaneously monitor ISO 3, 4, 5, and 6 (Classes 1, 10, 100, 1000)

0.5 to 5.0 μm particle counters: Use to simultaneously monitor ISO 5, 6, 7, and 8 (Classes 100, 1000, 10,000, 100,000) |

| Manifold Pump |

|

|

| Pumps required |

1 (single-phase) |

1 (3-phase) |

| Flow rate |

> 100 ft3/min |

> 150 ft3/min |

| Safety provision |

Automatic pump shutoff |

Automatic pump shutoff |

| Power |

105 – 125 VAC, 60 Hz or 220-240 VAC, 50 Hz 10.9 Amp, single-phase |

415 – 480 VAC, 60 Hz

5.0 Amp, 3-phase |

Dimensions

(l, w, h); weight |

10.6 x 11.2 x 16.2 in (27 x

28 x 41 cm); 42 lb (19 kg) |

16.7 x 15.0 x 20.0 in (47 x

38 x 51 cm); 75 lb (34 kg) |

| Manifold Module |

|

|

| Flow rate |

1.5 – 3 CFM per port (nominal) |

System Components Included:

Manifold module, control box, pump, operations manual, power cord, control cable, wall-mounting bracket, monitor exhaust tubing, pressure sensor tubing, pump tubing, and clamps.

Not included:

Particle counter/sensor, ISPs, sample tubing, communications cables (manifold to counter/sensor), PC, Facility Net or Pharmaceutical Net software.

|

Purge time

(between ports) |

15 seconds recommended |

| Cross talk (from other ports) |

< 0.1 % |

| Sample tubing |

Bev-A-Line XX® 1/2” OD, 3/8” ID (part # MI-153) |

| Sample tubing length and bend |

25’ – 125’ per port. Minimum 9” radius for Bev-A-Line XX® |

| Fittings provided |

16 (or 32) self-locking, 1/2” OD, Legris® (L-Legris) fittings |

| Vacuum required |

30” – 55” water |

| Mounting orientation |

Vertical; wall mounting bracket included |

| Power |

Provided by control box via controller cable |

Dimensions

(l, w, h); weight |

13.5 x 13.5 x 15.3 in (34 x 34 x 39 cm); 13.5 lb (6.1 kg) |

| Control Box |

|

|

Controlling

software |

Facility Net/Pharmaceutical Net (purchased separately) |

|

| Communications protocol |

Ethernet |

|

| Firmware setup modes |

RS-232, Telnet |

|

| Ethernet outlets (2) |

Network/Primary sensor |

|

| Automatic alarm |

Inadequate manifold vacuum |

|

| Mounting |

Vertical or horizontal; built-in mounting holes |

|

| Power |

105 – 125 VAC, 60 Hz; 220 – 240 VAC, 50 Hz |

|

Dimensions

(l, w, h); weight |

7 x 8.5 x12.5 in (18 x 22 x 32 cm); 11.5 lb (5.2 kg); painted steel box |

|

| System operating conditions |

Temperature: 59 – 95 ° (15 – 35 °C); Humidity: non-condensing |

|