As per ASTM C518 and ISO 8301, the FOX 200 HT Heat Flow Meter is a precise and user-friendly tool for determining thermal conductivity. The FOX Heat Flow Meter operates in independent or PC-controlled setups and delivers quick, precise results.

The device has responsive temperature control, digital thickness measurements, and patented thin film heat flux transducers. Being a flexible tool, the FOX 200 HT is particularly useful for measuring slices of cellular plastics.

- Complies with ISO 8301 and ASTM C518

- Simple to use, quick outcomes

- PC-based or standalone operation

- Solid-state heating and cooling

- Measurement of thickness to 0.025 mm

- Two Heat Flux Transducers with Thin Films

- Suitable for QC and R&D, WinTherm software increases adaptability

Specifications

Source: TA Instruments

| . |

. |

| Maximum Sample Thickness |

51 mm (2″) |

| Sample Size |

204 x 204 mm (8 sq. in.) |

| Temperature Range |

50 °C to 250 °C |

| Temperature Resolution |

±0.01 °C |

| Accuracy |

±2 % |

| Reproducibility |

±0.5 % |

| Thermal Conductivity Range |

0.005 to 0.35 W/m K

(0.035 to 2.4 BTU in/hr ft2 °F)

With FOX 200 HT External Thermocouple Kit:

up to 2.5 W/m K |

Proprietary Thin Film

Heat Flux Transducer |

75 mm x 75 mm (3 in)

Top and bottom |

Technology

Measurement Technique

A temperature gradient is created across the material’s thickness by sandwiching samples between two plates in the test stack. The plates can be positioned utilizing AutoThickness, where the instrument moves automatically to make contact with the sample, or to a user-defined thickness.

Four optical encoders, one at each corner of the plate, are used to measure the thickness of the in-situ sample. These encoders provide stable measurements to within 0.025 mm.

Advanced Heat Flux Measurement

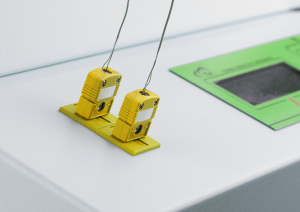

The LaserComp Heat Flux Transducer, which is made expressly for thermal conductivity measurements, is the central component of the measurement. To offer a measurement of the overall heat flow that is truly representative, the Heat Flux Transducer integrates over the full active surface, which is 75 × 75 mm or 3 sq. in. Since the transducer’s overall thickness is less than 1 mm, heat flow distortion is not possible.

Each transducer has a type K thermocouple bonded in the center, and both are sealed to guarantee steady precision throughout the instrument's lifetime. The thermocouples offer accurate measurements of the sample's surface temperature (with a resolution of ±.01 °C) and heat flow, as each one is positioned within 0.1 mm of the surface. Plate temperature control likewise makes use of the same thermocouples.

For samples with better heat conductivity, thermocouples can be physically affixed to the sample surfaces using the External Thermocouple Option, which will improve single-run accuracy. This option provides the thermocouples with auxiliary outlets on the instrument.

Precision Temperature Control

Low mass heaters, sophisticated temperature control electronics, and close sample temperature measurement enable the FOX series Heat Flow Meters to reach stable, precise thermal equilibrium rapidly. The same responsive thermocouples that are utilized in close contact with the sample to monitor the heat flux of the sample are the basis for plate temperature control.

Twenty times a second, an advanced temperature control algorithm checks the plate temperatures and quickly brings the system to the chosen equilibrium test condition. A digital signal processor manages plate temperature to within 0.01 °C. Temperature control that is quick, steady, and free from set-point overshoot is guaranteed by a multistage PID algorithm.

To achieve this, the solid-state elements’ heater power output is modified every 0.5 seconds. Testing with heat flow up or down is possible since the top and bottom plates can be heated or cooled. The extraordinarily quick attainment of set points is made possible by the low thermal mass design of the plates, the power of the DSP, and the power output board.

Complete Thermal Conductivity Solution

The heat flow meters of the FOX series can be used as standalone devices or in conjunction with a PC to save data and set up tests. A simple tool for adjusting experimental parameters, seeing test results in real-time, and storing and analyzing data is the WinTherm software program.

In either operating mode, the instrument electronics sense equilibrium based on predetermined parameters and, once a final value has been recorded, automatically advances to the next temperature on the schedule. There are also accessible specific heat measurements, with the WinTherm program guiding the data gathering and calculating process.

Optical Configurations

External Thermocouple Kit

Since thermocouples are affixed directly to the surfaces of the samples, interface resistance is not a factor, increasing measurement accuracy for samples with higher thermal conductivity (up to 2.5 W/m K). External thermocouples are inserted into machine-machined grooves in stiff specimens, or they are positioned in touch with the sample. The thermocouples on the outside have auxiliary outputs on instruments that are set up with this option.

Image Credit: TA Instruments

LaserComp FOX Series Heat Flow Meters

Video Credit: TA Instruments