Jun 21 2011

A new technique for producing artificial bone implants has been developed by Korean researchers. Published in the journal Science and Technology of Advanced Material (STAM), the technique combines two methods to approximate both types of bone tissue. By mimicking natural bone, it is hoped the implant material will better complement the natural regeneration process.

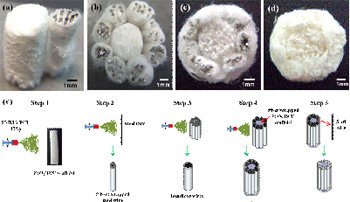

Most previous studies have focussed on producing cancellous bone, which has a spongy, honeycombed structure. However, artificial bones for practical applications must also imitate cortical bone, the hard, strong tissue found on the outer layers of bone. Cortical bone is less porous than cancellous bone, but contains canals through which the nutrients for bone formation flow. By developing a process to imitate this canal structure, the researchers made significant advances in the fabrication of artificial bones.

for the fabrication of artificial bone structures by combining sponge replica and electrospinning methods.

for the fabrication of artificial bone structures by combining sponge replica and electrospinning methods.

Bundles of polymer-based biomaterials* were wrapped around 0.3mm diameter steel wires by the method of "electrospinning", whereby fine fibres of material are drawn out by electric charge. These bundles were used to cover a scaffold of cancellous bone structure, made by the standard "sponge replica method" out of zirconia (ZrO2) and biphasic calcium phosphate (BCP). Removal of the steel wires resulted in interconnected structures mimicking small human bones.

The resulting structure had a high strength and a porosity of approximately 70% - similar to natural bone. Tests confirmed the artificial bone structure had a high degree of biocompatibility which is critical for real-world applications. However, more research is needed to evaluate the biological properties of this material both in vitro and in vivo.

The rapid ageing of the population makes bone loss and fracture a major worldwide problem and stimulates bone regeneration research. Biomimetic approaches to making artificial implants have attracted much attention, but the dependence of the healing process on interaction with the implant material requires close mimicry of the architecture of natural bone. This paper marks a significant advance in the development of materials and processing technology for the fabrication of artificial bone structures.

*HAp-loaded PMMA-PCL, or polymethylmethacrylate-polycaprolactone-hydroxyapatite