May 30 2013

Punching a large number of holes in thin sheet metal, without distorting the panel, and that in a single pass - that is now possible thanks to the new integrated flattening concept by TRUMPF. In the standard punching process, the punch draws material into the hole as it penetrates the sheet. That makes for compressive stress then, and tensile stress when the punch is withdrawn.

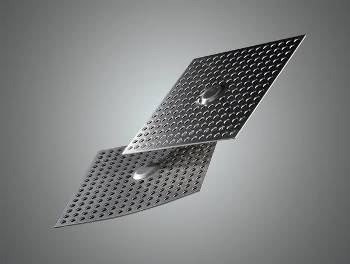

When using standard punching processes, thin material can be misshapen when many perforations are punched. Integrated leveling ensures flat and level sheets, produced on just a single machine. (Photo: TRUMPF Group)

When using standard punching processes, thin material can be misshapen when many perforations are punched. Integrated leveling ensures flat and level sheets, produced on just a single machine. (Photo: TRUMPF Group)

Especially when working low-gauge sheet metal with many holes, the material can become deformed. The result is a wavy sheet which will have to be flattened in a separate machine before processing can continue. With the integrated flattening, this extra step is no longer necessary. The function – available both on the thoroughly productive TruPunch 5000 and on the high-end TruMatic 7000 punch laser machine – induces opposing stresses. Thus it ensures undistorted sheet metal panels and in this way shortens the entire working process.

For Ralph Hemberger, head of production scheduling at Alfred Rexroth GmbH & Co. KG in Veichtshöchheim, Germany, this new function represents a considerable labor saving. “The integrated flattening feature incorporated into the TruMatic 7000 reduces logistic expenditures because the components no longer have to be transferred to one of our other shops for flattening.” The company produces speaker covers. Since these parts are visible, the optical requirements are high. Here keeping the sheet flat, combined with the great ratio of punched area in these perforated grids, represented a challenge. Integrated flattening proved to be a proper solution. “The new process lets us carry out the entire operation, including punching and embossing, all in one step while achieving a high degree of flatness.” Hemberger confirms.

The central components in integrated flattening are the punching tools made by TRUMPF. A convex die and a stripper with a recess and special coating make sure that the sheet metal isn’t deformed. The convex die presses the sheet metal, from underneath, against the stripper; the sheet metal is over-bent at this point. The concave stripper counteracts by pressing the sheet metal, raised by the convex die, back downward at the edge of the die. The overbending of the materials creates counter-stresses which offset the compressive and tensile stresses caused by the punching process. In this way the stresses are compensated and the sheet metal is flat when it leaves the machine.