Feb 27 2014

The University of Cincinnati is a partner in the Digital Lab for Manufacturing, an applied-research institute organized by UI Labs, a Chicago-based research and commercialization collaborative. It will both develop and demonstrate digital manufacturing technologies and deploy and commercialzie these technologies across key manufacturing industries.

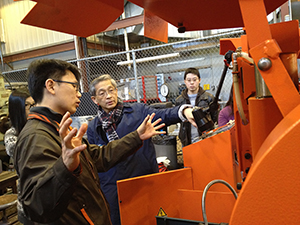

Ann Kao (UC IMS Center), Peng Huang (VP of Cosen), Prof. Jay Lee (UC IMS Center), Shanhu Yang (UC IMS Center) with IMS Center Cosen Band Saw Testbed.

Ann Kao (UC IMS Center), Peng Huang (VP of Cosen), Prof. Jay Lee (UC IMS Center), Shanhu Yang (UC IMS Center) with IMS Center Cosen Band Saw Testbed.

Yesterday, President Obama announced that the United States Department of Defense will support the Digital Lab, housed within the Digital Manufacturing and Design Innovation (DMDI) Institute. Along with the $70 million cooperative agreement, UI Labs has secured an additional $250 million in support from partners in industry, government, community and universities.

Digital manufacturing is the use of an integrated, computer-based system comprised of simulation, three-dimensional (3D) visualization, analytics and various collaboration tools to create product and manufacturing process definitions simultaneously.

UI Labs brings together 40 industry partners and more than 30 academia, government and community partners (including UC), and over 500 supporting companies and organizations to create the Digital Lab. Among the industry partners are General Electric, Rolls-Royce, Procter & Gamble, Dow, Lockheed Martin, Siemens, Boeing, Deere, Caterpillar and Microsoft.

Participating university and government partners are regionally anchored in the Midwest extending to Colorado, New York, Oregon and Texas.

As stated by U.S. Congressman Steve Chabot in his letter of support: “. . . Ohio and the Midwest are home to some of the country’s most robust manufacturing activity. Manufacturing activities account for almost 16 percent of Ohio’s total economic output and employ over 12 percent of our workforce. With the combined resources from world-class partners in the Midwest like Proctor & Gamble and other universities and companies in the region and beyond, Digital Labs will help develop the digital manufacturing capabilities of our military and other sectors, leading to substantial job creation and expansion of U.S. advanced manufacturing capability.”

One of the first proposed projects to potentially receive funding via the national grant is “Intelligent Machining Toolkit” which involves a team that combines the world-class academic expertise of the University of Cincinnati and University of Michigan (UM) with industrial expertise in adaptive manufacturing (GE), non-contact sensors (Hexagon), CAD/CAM software and NC controls (Siemens), as well as casting machining expertise and compelling application demonstrations at Quad Cities Manufacturing Lab (QCML, within the Rock Island Arsenal) and Sivyer Steel Corporation.

This project will tap into one of UC’s hallmark areas of technology leadership involving the University’s NSF I/UCRC for Intelligent Maintenance Systems (IMS Center), widely recognized as a world leader in frontier technologies and methodologies for intelligent machine monitoring and prognostics. The Center has extensive experience in interdisciplinary collaboration with industry, government and academia having conducted over 100 successful projects with more than 80 global organizations from 15 countries, making the Center an ideal partner in this project and in the Digital Lab.

UC’s involvement in the “Intelligent Machining Toolkit” project is crucial to the development of a smart “plug and play,” user-friendly hardware and software toolkit that enables legacy or modern CNC machines and industrial robots to become self-aware and self-predict for virtual metrology. The toolkit will demonstrate improved cycle time, yield and productivity in casting set up and machining.

Current practice requires extensive time and skill to set up and machine large castings. Due to casting variation casting machining yields are sub-optimal. All of this leads to higher costs and longer cycle times, which the project will alleviate. Besides casting machining, adaptive machining technology is often required in machining of advanced composites, an area of increasing importance to the DoD.

Key personnel involved in this project include: Principal Investigator Stephen R. Biller, Chief Manufacturing Scientist at GE Global Research; Jun Ni, S.M. Wu Collegiate Professor of Manufacturing Science and director of the S.M. Wu Manufacturing Research Center at the University of Michigan; and Jay Lee, Ohio Eminent Scholar, L.W. Scott Alter Chair Professor and Distinguished Research Professor at the University of Cincinnati as well as director of the IMS Center.

For the White House Press release of Feb. 25, 2014, select http://www.whitehouse.gov/the-press-office/2014/02/25/president-obama-announces-two-new-public-private-manufacturing-innovatio

For more on UC's IMS Center select http://www.imscenter.net/

For information about UC's College of Engineering and Applied Science select www.ceas.uc.edu