EDAX, LLC. a leader in X-ray microanalysis and electron diffraction instrumentation, has launched the Atom Probe Assist, a new tool designed to help users of atom probe tomography prepare specimens for faster and more efficient analysis than previously possible.

Atom Probe Assist reduces the total time needed to obtain high-quality atom probe data and accelerates progress in understanding questions in materials research, such as grain boundary segregation.

Atom Probe Tomography (APT) is a material analysis technique that provides 3D chemical composition and imaging at the atomic scale and is uniquely suited to analysis of grain boundary segregation.

“Atom probe tomography is an exciting characterization technique that provides chemical composition information and three-dimensional visualization at the atomic scale. It is uniquely suited for analyzing grain boundary segregation in materials, a phenomenon than influences a number of critical material properties,” notes Matt Nowell, EBSD Product Manager at EDAX.

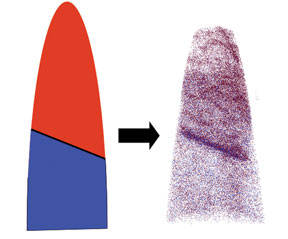

“To better understand grain boundary segregation, atom probe data must be collected from a grain boundary that is prepared from a larger sample. Atom probe specimens are formed into small cones, and the grain boundary must be positioned within approximately 200 nm from the specimen apex for successful data collection.

“Traditionally this preparation is very inefficient. Samples are electropolished, and subsequently analyzed in a Transmission Electron Microscope (TEM) to determine if the grain boundaries are adequately positioned for analysis. With this approach it is difficult to control the final position of the grain boundary, and it is time-intensive to verify this position in the TEM. The result is a low yield of useable specimens.”

The Atom Probe Assist from EDAX provides a new method of preparing atom probe specimens that is faster and safer and provides a higher yield of useable specimens. This approach uses Transmission-Electron Backscatter Diffraction (t-EBSD) to collect crystallographic information from the specimen to quantifiably determine grain boundary position with high spatial resolution and precision.

Designed for use with a Focused Ion Beam (FIB), the specimens are prepared using annular ion beam milling, and the position of the grain boundary is checked after each milling step. Once the grain boundary is located in the optimal position for analysis, the preparation is complete. Preparation and validation occurs in a single instrument, removing the need to transfer the sample with a higher risk of damage or loss.

“There is great synergy between the Atom Probe Assist and Atom Probe characterization. Not only can specimens be prepared more efficiently, but the tool also can be used to identify different grain boundary types, which influence material performance, by using traditional EBSD to help guide site-specific specimen preparation. The Atom Probe Assist has been designed with specialized features to make this process easy to operate while providing quality data,” adds Mr. Nowell.

About AMETEK EDAX

EDAX is the acknowledged leader in Energy Dispersive Microanalysis, Electron Backscatter Diffraction and X-ray Fluorescence instrumentation. EDAX designs, manufactures, installs and services high-quality products and systems for leading companies in the semiconductor, metals, geological, pharmaceutical, biomaterials, and ceramics markets.

Since 1962, EDAX has used its knowledge and experience to develop ultra-sensitive silicon radiation sensors, digital electronics and specialized application software that facilitate solutions to research, development and industrial requirements.

EDAX is a unit of the Materials Analysis Division of AMETEK, Inc., which is a leading global manufacturer of electronic instruments and electromechanical devices with annual sales of $4.0 billion.