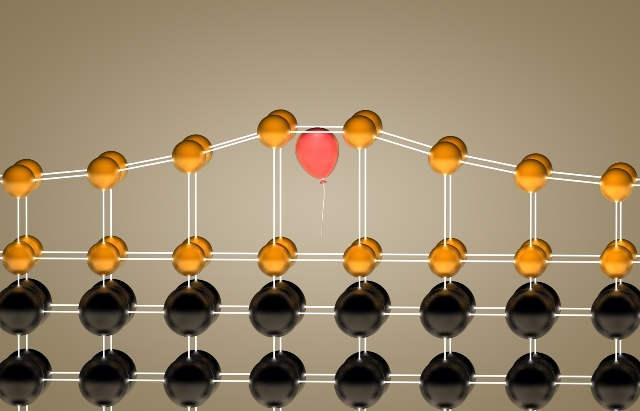

Inserting helium atoms (visualized as a red balloon) into a crystalline film (gold) allowed Oak Ridge National Laboratory researchers to control the material’s elongation in a single direction.

Inserting helium atoms (visualized as a red balloon) into a crystalline film (gold) allowed Oak Ridge National Laboratory researchers to control the material’s elongation in a single direction.

Complex oxide materials possess unique properties, such as colossal magnetoresistance and superconductivity which cannot be easily controlled. This new method, which has been developed at ORNL, furthers our understanding of complex oxide materials.

This method helps to control a crystalline material’s elongation in a single direction. This is done without any damage to the crystalline structure and without any modification to the length in other directions. The addition of a handful of helium ions to a complex oxide material allows the control over electronic and magnetic properties which was not previously possible.

By putting a little helium into the material, we’re able to control strain along a single axis. This type of control wasn’t possible before, and it allows you to tune material properties with a finesse that we haven’t previously had access to.

Zac Ward, Oak Ridge National Laboratory

In complex oxides, electrons are bound in an intricate manner. Hence any strain that occurs initiates modifications in its electronic properties. The strain may be from stretching, pushing or pulling of the structure. Attempts by scientists to study and utilize these materials have been made difficult due to the ripple effect.

In this study, this technique has been demonstrated on LSMO, which is a common oxide material. However, the researchers believe that their new technique could be used in fundamental physics studies, and also in functionality-driven material science research.

“Complex oxides are where we expect an immediate impact, but this technique should be an important new tool to use on any material where crystal symmetry affects functionality,” Ward said.

The findings of this study would help advance commercialization of complex materials, and the ability to tune the properties of materials will also benefit commercialization. The processing involved is similar to the methodologies involved in the semiconductor industry.

“Our strain doping technique demonstrates a path to achieving this need, as it can be implemented using established ion implantation infrastructure in the semiconductor industry,” Ward said.

After a material has been produced, a few helium ions are added to this material using a low-energy ion gun. As this process is reversible, heating the material under high temperature conditions in vacuum, can help remove the helium. Strain tuning methods that had been developed earlier, cause modifications in the material in all directions. Furthermore, they could not be reversed or altered later.

“We can easily control the amount of strain and how deep that strain is inside the material,” Ward said. “By controlling the number of helium atoms inserted into an epitaxial film, we select a strain state in one direction while the other two directions are held in place by the substrate.”

Theoretical research with the aim of modeling complex materials for understanding and predicting their behavior would also benefit from this novel technique.

“The complexity of these materials requires a huge equation to explain their behaviors,” Ward said. “Normal strain tuning methods require you to change many variables in that equation which means that you don’t really know which one is giving you a specific reaction. In our case, there’s one variable. You can feed in a single term and try to break through that complexity a little bit by simplifying it. This is a great method to experimentally probe theoretical models.”

The research team has published their technique in a paper entitled Strain doping: Reversible single axis control of a complex oxide lattice via helium implantation in the Physical Review Letters journal.