Researchers at Drexel University have developed a new material-making method for creating an entirely new stable material for storing energy by 'sandwiching' atomic layers of materials such as molybdenum, titanium and carbon.

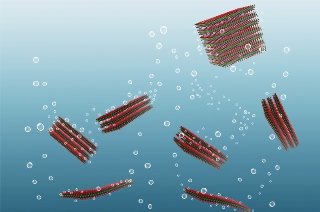

Drexel materials researchers have taken the next step in a progression of advances they've been making in the invention of energy-storage materials. Their new method allows for two-dimensional layers of disparate elements to be stacked together. This development will yield a variety of new, durable materials with energy storage capabilities.

Drexel materials researchers have taken the next step in a progression of advances they've been making in the invention of energy-storage materials. Their new method allows for two-dimensional layers of disparate elements to be stacked together. This development will yield a variety of new, durable materials with energy storage capabilities.

Babak Anasori, PhD, postdoctoral researcher, led a team of researchers from Drexel’s Department of Materials Science and Engineering to develop the material-making method. This method enabled the production of a stable material with predictable, uniform properties by joining disparate elemental layers. The team demonstrated the effectiveness of this method by creating 2D materials using carbon, titanium and molybdenum.

“By ‘sandwiching’ one or two atomic layers of a transition metal like titanium, between monoatomic layers of another metal, such as molybdenum, with carbon atoms holding them together, we discovered that a stable material can be produced,” Anasori said. “It was impossible to produce a 2-D material having just three or four molybdenum layers in such structures, but because we added the extra layer of titanium as a connector, we were able to synthesize them.”

This finding signifies a new method for combining elemental materials to create superstrong composites and building blocks of energy storage technology. Superstrong composite materials are used in body armor and phone cases. Batteries, supercapacitors, and capacitors are considered to be building blocks for storage of energy. Different combinations of atom-thick layers exhibit new properties, and the team believes that some of these materials could demonstrate durability and energy storage that is not proportional to its size, which could advance new technologies.

“While it’s hard to say, at this point, exactly what will become of these new families of 2D materials we’ve discovered, it is safe to say that this discovery enables the field of materials science and nanotechnology to move into an uncharted territory,” Anasori said.

For over a decade, nanomaterials researchers at Drexel have been attempting to combine 2D sheets of elements in an organized manner to develop new materials. However, it has been very difficult to organize elements at the atomic level.

“Due to their structure and electric charge, certain elements just don’t ‘like’ to be combined,” Anasori said. “It’s like trying to stack magnets with the poles facing the same direction—you’re not going to be very successful and you’re going to be picking up a lot of flying magnets.”

Researchers at Drexel found a method to get around this difficulty. Two decades ago, the head of the MAX/MXene Research Group, Distinguished Professor Michel W. Barsoum, PhD, discovered a MAX phase material. A MAX phase is considered to be something similar to the primordial ooze that generated the first organisms. The various elements of the finished product are in the MAX phase, and some sort of order has to be imposed upon them.

In 2011, Michel W. Barsoum, PhD and Yury Gogotsi, PhD, Distinguished University and Trustee Chair professor in the College of Engineering and head of the Drexel Nanomaterials Group, imposed this order by creating MXene, which is a stable, layered, 2D material.

The researchers used an acid to etch out specific layers of aluminum atoms from a MAX phase block for creating MXenes.

“Think of MXene synthesis like separating layers of wood by dunking a plywood sheet into a chemical that dissolves the glue,” Anasori said. “By putting a MAX phase in acid, we have been able to selectively etch away certain layers and turn the MAX phase into many thin 2D sheets, which we call MXenes.”

The discovery of MXenes for energy storage was a revelation. Graphene was the first 2D material that was considered promising for energy storage, but as it is made up of only one element, and is in the form of a single sheet of carbon atoms, its form cannot be modified easily. Hence, its capabilities to store energy are limited. MXenes, on the other hand, have surfaces that allow them to store more energy.

Researchers then began to conduct studies with “transition metals” in the Periodic Table, and they produced MAX phases that they etched into MXenes with different compositions. The team tested the energy storage properties of the various compositions.

"We had reached a bit of an impasse when trying to produce a molybdenum containing MXenes,” Anasori said. “By adding titanium to the mix we managed to make an ordered molybdenum MAX phase, where the titanium atoms are in center and the molybdenum on the outside.”

Researchers at Oak Ridge National Laboratory’s FIRST Energy Frontier Research Center performed theoretical calculations, which showed that it was possible to utilize this method to create up to 25 new materials, using various combinations of titanium, molybdenum and other such transition metals.

“Having the possibility to layer different elements at the thinnest form of material known to the scientific community leads to exciting new structures and allows unprecedented control over materials properties,” Barsoum said. “This new layering method gives researchers an unimaginable number of possibilities for tuning materials’ properties for a variety of high-tech applications.”

Using other metals such as tantalum, niobium and vanadium instead of titanium could help create more materials with possible new physical properties that support various applications such as energy storage.

“This level of structural complexity, or layering, in 2D materials has the potential to lead to many new structures with unique control over their properties,” Gogotsi said. “We see possible applications in thermoelectrics, batteries, catalysis, solar cells, electronic devices, structural composites and many other fields, enabling a new level of engineering on the atomic scale.”

The team has published their discovery in the ACS Nano journal.