Nov 5 2015

A team of scientists from the University of California, Riverside have discovered that certain commercially available 3D printers create parts that are harmful to zebrafish embryos. This latest research raises concerns regarding the disposal of waste materials and objects created by 3D printers.

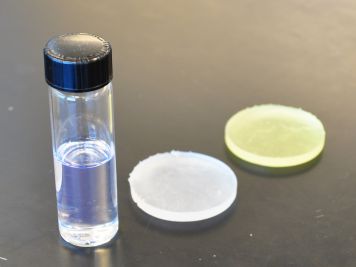

From lexft, 3D printing liquid, 3D-printed piece from liquid resin and liquid resin piece treated with ultraviolet light.

From lexft, 3D printing liquid, 3D-printed piece from liquid resin and liquid resin piece treated with ultraviolet light.

“These 3D printers are like tiny factories in a box,” said William Grover, an assistant professor of bioengineering in the Bourns College of Engineering. “We regulate factories. We would never bring one into our home. Yet, we are starting to bring these 3D printers into our homes like they are toasters.”

For the study, two standard 3D printers were taken: Stratasys’ Dimension Elite printer and Formlabs’ Form 1+ stereolithography printer. The former melts plastic to produce a component, while the latter employs light to convert a liquid resin into a solid one. While it was observed that the objects produced by these printers were harmful to zebrafish embryos, the liquid-based printer produced the most toxic parts.

A year ago, a 3D printer was purchased by Grover for his research lab, and this led to this breakthrough study. Shirin Mesbah Oskui, a graduate student working in Grover’s laboratory, was creating tools to analyze zebrafish embryos and was planning to employ the 3D printer for this purpose. Conversely, she soon discovered that these embryos die following exposure to objects produced by the printer. Based on these latest finding, the team went ahead to examine the effect and toxicity of objects created by both 3D printers.

Each printer was used to produce disc-shaped objects, which had a diameter of 1” and were later placed in petri dishes that contained zebrafish embryos. The embryos were examined for both hatch and survival rates and tracked for any sign of developmental abnormalities.

When compared to control embryos, slightly reduced average survival rates were seen in embryos exposed to parts produced by the plastic-melting printer, while the embryos exposed to parts created by the liquid-resin printer had relatively more reduced survival rates, where all the embryos were dead by day seven. Among the few embryos that hatched when subjected to parts printed by the liquid-resin printer, all of them had developmental abnormalities.

In order to reduce the toxicity of objects created by the liquid-based printer, Oskui further went on to study techniques, including a simple post-printing treatment, which can possibly reduce the toxicity of objects produced by the liquid-resin printer. She discovered that when these parts were exposed to UV light for a period of 1h, they became less harmful to the embryos. A patent for this research has been filed by the UC Riverside Office of Technology Commercialization.

The results of the study have been illustrated in a paper titled, “Assessing and Reducing the Toxicity of 3D-Printed Parts,” which was reported in the journal, Environmental Science and Technology Letters. Other researchers who took part in the study were Wei Shi and Chunyang Liao, both of whom serve in Gan’s laboratory; Daniel Schlenk and Jay Gan, professors in the Department of Environmental Sciences; and Graciel Diamante, a graduate student working with Schlenk.

The study comes at a time where 3D printers are increasingly being used in many applications. In fact, the value of the global 3D printing market increased from $288 million to $2.5 billion between 2012 and 2013. According to Canalys’ report, this value would increase to $16.2 billion by 2018. The cost of 3D printers is getting reduced drastically. This means, printers using melted plastic can now be obtained at an affordable price. In fact, consumers can purchase the liquid-based printer used in this analysis for about $3,000. Such printers, which were earlier used in research laboratories and industry, are now being used in small businesses and homes.

This latest study brings the focus to regulate materials employed for producing 3D printed objects. As such, the Toxic Substances Control Act, administered by the Environmental Protection Agency (EPA), will regulate the substances utilized for producing 3D-printed objects. However, both printer users and researchers are often unaware of the exact nature of these substances because such data is not furnished by printer manufacturers.

The toxicity of the components used in 3D printer materials will be further studied by the research team, both separately and on a combined basis. The study will also be extended to analyze the effect of the material on human health. However, there are still many issues regarding the safe disposal of waste materials produced by 3D printers. For the time being, such products can be deployed to a hazardous waste center, according to the research team.

“Many people, including myself, are excited about 3D printing,” Grover said. “But, we really need to take a step back and ask how safe are these materials?”

The National Science Foundation’s Instrument Development for Biological Research Program partly funded the study through Grant DBI-1353974.