May 25 2016

A complex process is required to synthesize dilute hydrogen peroxide at the large scale and this process seems to be economically unfeasible for most industrial applications except for a few industrial facilities.

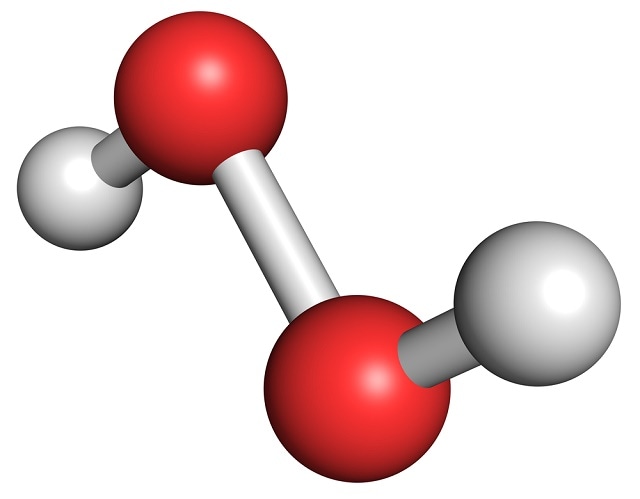

Image Credit: molekuul_be | Shutterstock.com

Image Credit: molekuul_be | Shutterstock.com

Engineers and chemists have been working for a long time to develop simpler approaches. One significant challenge refers to the process of stabilizing the material once it develops, because yields are limited by the propensity of the molecule to break down over the same materials that are used for its synthesis.

Biological and chemical engineers from the University of Wisconsin–Madison have gained key insights into the decomposition mechanism of the compound. This knowledge, published in Proceedings of the National Academy of Sciences, could make room for cost-effective and efficient single-step strategies for developing hydrogen peroxide.

Hydrogen peroxide that is highly watered-down is used by consumers to clean scrapes and minor cuts, but it is also possible to use this chemical for a variety of industrial processes, like manufacturing flexible foam seat cushions or making precursor chemicals for flame retardants.

Most applications will require only the dilute form of hydrogen peroxide, but production methods will depend more on the large facilities that have the ability to synthesize huge volumes of highly concentrated chemicals. This requires transporting concentrated hydrogen peroxide solutions over long distances to the end user, which involves considerable cost.

A single-pot reaction would permit on-site production and make hydrogen peroxide an economically feasible oxidant for a number of chemical processes, in particular to replace more environmentally harmful oxidants such as chlorine.

Tony Plauck, Doctoral Student UW–Madison

In 1914, scientists suggested a single-step procedure to synthesize hydrogen peroxide using pure hydrogen and oxygen in the presence of a catalyst, which speeds up the chemical reaction by reducing the energy barriers that prevent the components from combining. However, the catalyst remains unaffected.

However, when the volume of the final hydrogen peroxide product increases in the vessel comprising the mixture, the catalyst turns out to be capable of facilitating a subsequent undesirable chemical reaction in which hydrogen peroxide disintegrates into water and oxygen gas in a process known as decomposition.

One of the biggest catalytic challenges is finding a material that can actively produce hydrogen peroxide, but also something inactive towards decomposing hydrogen peroxide, which is a very thermodynamically favorable reaction.

Tony Plauck, Doctoral Student UW–Madison

Palladium-based catalysts are some of the materials that have been increasingly analyzed for the synthesis of direct hydrogen peroxide. Researchers have examined how hydrogen and oxygen combine and chemically react on areas called active sites present on the surface of the catalyst. Palladium is also capable of catalyzing the decomposition reaction, which could result in rapid breaking down of the hydrogen peroxide developed under these conditions.

Typical palladium catalysts exist as tiny, highly dispersed palladium nanoparticles, which contain a variety of surface features that may vary in their ability to decompose hydrogen peroxide. If we understand where and how hydrogen peroxide primarily decomposes, we can propose some design criteria for future iterations of palladium catalysts.

Tony Plauck, Doctoral Student UW–Madison

Chemical and biological engineering professors Manos Mavrikakis and James Dumesic, who are Plauck’s advisors on the project, specialize in both experimental and theoretical approaches in catalysis. Their proficiency in the computational methods like density functional theory and microkinetic modeling, enabled them to explain the experimentally observed decomposition reaction in a detailed and accuarte manner.

Hydrogen peroxide is currently prepared by a highly polluting process. These insights open new avenues for the direct synthesis of a chemical that, among others, is needed in large volumes for the laundry and paper bleaching industry.

Manos Mavrikakis, Professor, UW-Madison

Computational modeling was used by the researchers to examine varied surface features of palladium nanoparticles that are possible of playing a major role in the decomposition of hydrogen peroxide. Experimentally observable parameters of the reaction were predicted based on the theoretical models. One such parameter refers to the rate of hydrogen peroxide decomposition. The researchers then carried out those experimental measurements and reviewed different aspects of their models till the theoretical predictions matched with the experiments.

The final results pointed out that the palladium nanoparticles’ multiple surface features are capable of contributing to the total hydrogen peroxide decomposition activity performed by the catalysts. The models further provided in-depth knowledge about how the decomposition reaction can be suppressed on palladium.

The research received support as part of a Dow Chemical Company University Partner Initiative with UW–Madison, and Dow’s Eric E. Stangland also contributed to the work.