Jun 15 2016

A new type of material is being studied by researchers that could aid in recycling and reducing waste in nuclear fuels by capturing radioactive gases emitted during reprocessing. Traditional technologies used for removing such gases work at very low energy-intensive temperatures. The novel material, operating at ambient temperature, can possibly save energy and make reprocessing less expensive and relatively cleaner. Moreover, the reclaimed materials can be reused at a commercial level. The results of the study have been reported in Nature Communications.

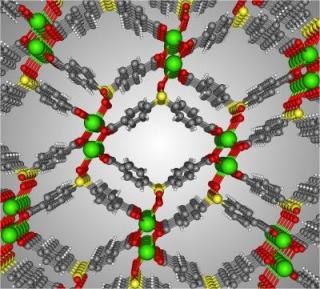

A molecular model of a new metal organic framework (MOF) which selectively traps xenon, a gas that is released during reprocessing of nuclear fuel. (Credit Illustration courtesy of PNNL)

A molecular model of a new metal organic framework (MOF) which selectively traps xenon, a gas that is released during reprocessing of nuclear fuel. (Credit Illustration courtesy of PNNL)

The work is a collaborative effort between computer modelers and experimentalists who are investigating the properties of materials called metal-organic frameworks, also known as MOFs.

"This is a great example of computer-inspired material discovery," said materials scientist Praveen Thallapally of the Department of Energy's Pacific Northwest National Laboratory. "Usually the experimental results are more realistic than computational ones. This time, the computer modeling showed us something the experiments weren't telling us."

Waste avoidance

Plutonium and uranium, which form most of the used fuel, generally end up as waste products. Hence, these materials can be reused by recycling nuclear fuels. As such, scientists are investigating technologies that allow for safe, reliable, and efficient recycling of nuclear fuels for future use.

An international, multi-institutional team is exploring materials to substitute inefficient and expensive recycling processes. One major step involved is collecting krypton and xenon, which are radioactive gases and arise during reprocessing.

In order to trap these radioactive gases, cryogenic techniques are used by traditional technologies which involve bringing the entire gas streams to a temperature where water freezes. However, these approaches are not only costly, but also energy intensive.

Thallapally, along with Berend Smit and Maciej Haranczyk of Lawrence Berkeley National Laboratory and others, has been investigating MOFs, which can possibly trap krypton and xenon gases without using the cryogenic methods. These materials contain microscopic pores, which are so small that only one molecule can be accommodated inside a single pore. When a gas species shows a higher affinity for the pore walls than other gas species, then MOFs can be used for isolating gaseous mixtures by selectively adsorbing them.

In order to locate the best possible MOF for separation of krypton and xenon gases, computational chemists screened 125,000 potential MOFs for their capability to trap the gases. Haranczyk and Smit headed this study. Krypton and xenon gases are part of chemically inert elements known as noble gases, although they can exist in different radioactive varieties. For the study, computing resources at National Energy Research Scientific Computing Center (NERSC), a DOE Office of Science User Facility at LBNL, were used by the research team.

Identifying the optimal material for a given process, out of thousands of possible structures, is a challenge due to the sheer number of materials. Given that the characterization of each material can take up to a few hours of simulations, the entire screening process may fill a supercomputer for weeks. Instead, we developed an approach to assess the performance of materials based on their easily computable characteristics. In this case, seven different characteristics were necessary for predicting how the materials behaved, and our team's grad student Cory Simon's application of machine learning techniques greatly sped up the material discovery process by eliminating those that didn't meet the criteria.

Haranczyk

The computer models were able to detect the MOF that selectively trapped the xenon gas and had a pore size near to the size of a xenon atom, SBMOF-1, which was examined in the PNNL lab.

As soon as SBMOF-1 preparation was optimized, Thallapally and the PNNL team examined the material by passing a combination of gases through it, including a non-radioactive krypton and xenon gases and then quantifying the outcome at the other end. It was observed that xenon was overpowered by krypton, oxygen, nitrogen, carbon dioxide, and helium, suggesting that xenon gets trapped within the pores of SBMOF-1 until the material is saturated by the gas.

Other tests were carried out which demonstrated that when xenon is not present, the SBMOF-1 traps the krypton gas. Earlier, during real separations, operators would capture both the gases by passing the gas streams two times through the SBMOF-1.

The researchers also tested the ability of SBMOF-1 to hang onto xenon in high humidity conditions. Humidity impedes with cryogenics, and it is also important to dehydrate the gases prior to putting them via the ultra-cold method, which is another time-consuming process. However, SBMOF-1 performed commendably, capturing over 85% of the amount of xenon in high humidity conditions as it did in dry conditions.

In the last step of collecting krypton or xenon gas, the MOF material is placed under a vacuum, which absorbs the gas from the molecular cages for safe storage. A lab test assessed the material’s stability by repeatedly filling the material with xenon and then removing the said gas. Following 10 repeated cycles, the SBMOF-1 was able to collect just as much xenon as the initial cycle, suggesting a high level of stability for prolonged use.

According to Thallapally, this stability is due to the way in which SBMOF-1 interacts with the xenon gas. The relationship is simply physical rather than chemical reactions between the gases and the molecular cages. The material can survive for a much longer time without constant need to go through chemical reactions.

A model finding

While SBMOF-1 has been shown to be a suitable candidate for reprocessing of nuclear fuels, acquiring these results was not actually easy. For SBMOF-1 preparation, the team used an earlier worked out procedure from Stony Brook University. Part of that procedure involves activating the SBMOF-1 by heating it up to 300oC temperature, which is thrice the temperature of boiling water. This activation step cleans out the residual material in the pores during MOF synthesis. However, lab tests of the activated SBMOF-1 demonstrated that the material did not behave as well as it should, according to the computer modeling results. These lab experiments were repeated by the PNNL research team, but this time, SBMOF-1 was activated at a lower temperature, i.e., 100oC or the exact temperature of boiling water. The researchers then exposed the material to the same laboratory tests and observed that SBMOF-1 behaved as predicted, and was also better than at the higher activation temperature. However, this phenomenon remains unclear. Hence, to find out the origin of this discrepancy, the research team modeled what happened to SBMOF-1 at 300oC temperature, and unpredictably the pores compressed in on themselves.

When we heated the crystal that high, atoms within the pore tilted and partially blocked the pores. The xenon doesn't fit.

Thallapally

Equipped with these innovative experimental and computational insights, the team further examined other MOFs, including SBMOF-1 for recycling of nuclear fuels. These MOFs may also be able to trap other noble gases like radon, which typically pools in certain basements.