Jun 21 2016

A team of scientists in South Korea have developed ultra-thin photovoltaics with flexibility that is sufficient enough to wrap around the average pencil. The bendy solar cells have the potential to power wearable electronics such as smart glasses and fitness trackers. The results have been reported in Applied Physics Letters, from AIP Publishing.

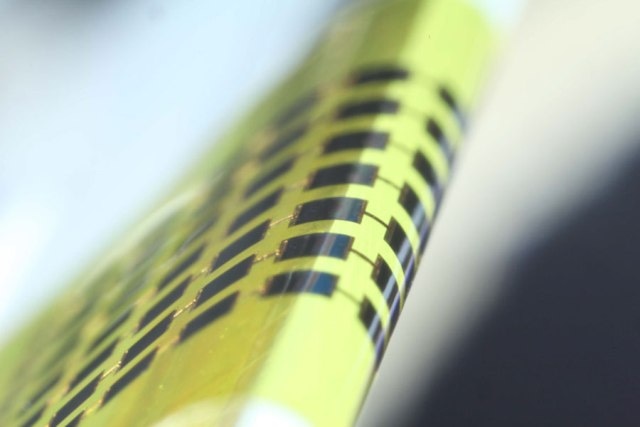

Ultra-thin solar cells are flexible enough to bend around small objects, such as the 1mm-thick edge of a glass slide, as shown here. CREDIT: Juho Kim, et al/APL

Ultra-thin solar cells are flexible enough to bend around small objects, such as the 1mm-thick edge of a glass slide, as shown here. CREDIT: Juho Kim, et al/APL

Thin materials have better flexibility compared to the thick materials, for instance a piece of paper compared to a cardboard shipping box. This variation is caused because the material’s stress increases a lot from the central plane when made to bend. Thick sheets are difficult to bend as they have more material further out.

Our photovoltaic is about 1 micrometer thick.

Jongho Lee, Engineer, Gwangju Institute of Science and Technology

One micrometer is extremely thinner in comparison to an average strand of human hair. Generally, standard photovoltaics are hundreds of times thicker. Most of the other thin photovoltaics are also found to be 2 to 4 times thicker.

The team used semiconductor gallium arsenide to develop the ultra-thin solar cells. The cells were directly stamped onto a substrate that is flexible. The stamping was performed without the use of an adhesive that would add to the thickness of the material.

Next, the cells were cold webbed to the electrode present on the substrate and this was carried out by applying pressure at 170ºC and then melting a material’s top layer. This material is known as photoresist that was used as a temporary adhesive. Later, the photoresist was peeled off, resulting in the direct metal-to-metal bond.

The metal bottom layer also acted as a reflector in order to direct stray photons back into the solar cells. The team then analyzed the efficiency of the device at transforming sunlight to electricity and discovered that it was similar to thicker photovoltaics. Bending tests were carried out and the team observed that the cells were capable of wrapping around a radius measuring almost 1.4 millimeters.

Several analysis of the cells were performed, identifying the fact that the cells experience one-fourth the amount of strain of those cells with a thickness of 3.5 micrometers.

The thinner cells are less fragile under bending, but perform similarly or even slightly better.

Jongho Lee, Engineer, Gwangju Institute of Science and Technology

Various other teams have reported on the existence of solar cells that are almost 1 micrometer in thickness, but have also developed the cells through a number of ways, for instance by removing the complete substrate through an etching process.

Lee and his colleagues developed the new technique by transfer printing instead of the etching process and this technique may be used to produce extremely flexible photovoltaics comprising a small volume of materials.

Lee stated that it could be possible to blend the thin cells onto glass frames or fabric, and these cells might also be able to power future wearable electronics.