Aug 24 2016

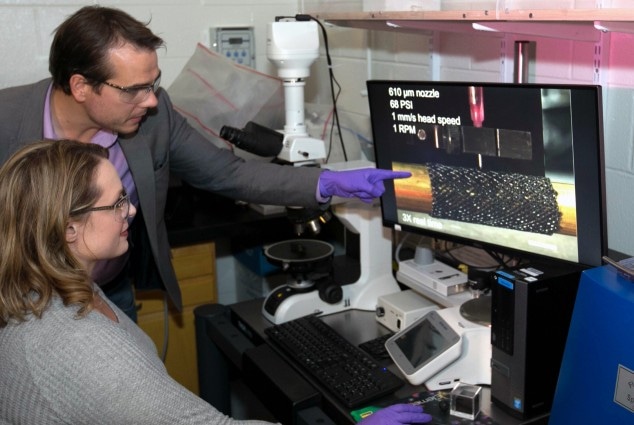

LLNL researchers have successfully demonstrated the 3D printing of shape-shifting structures that can fold or unfold to reshape themselves when exposed to heat or electricity. Here, researchers Jennifer Rodriguez and Jim Lewicki examine a stent that can expand when exposed to heat. (Photos by Julie Russell/LLNL)

LLNL researchers have successfully demonstrated the 3D printing of shape-shifting structures that can fold or unfold to reshape themselves when exposed to heat or electricity. Here, researchers Jennifer Rodriguez and Jim Lewicki examine a stent that can expand when exposed to heat. (Photos by Julie Russell/LLNL)

Researchers from Lawrence Livermore National Laboratory (LLNL) have 3D printed shape-shifting structures capable of folding or unfolding to reshape themselves whenever they are exposed to electricity or heat.

The micro-architected structures were created using a conductive, environmentally responsive polymer ink formulated at the LLNL.

In a paper published recently by the Scientific Reports journal, the LLNL team revealed a method to produce boxes, spheres and spirals from shape memory polymers (SMPs) - bio-based "smart" materials that display shape-changes when exposed to the suitable temperature or when resistively heated.

The method of using responsive materials in 3D printing, frequently referred to as "4D printing" is not new, however the LLNL researchers are the first to integrate the process of 3D printing and subsequent folding using origami methods, with conductive smart materials to construct complex structures.

In the research paper, the team illustrates the development of key shapes from an ink produced from soybean oil, carbon nanofibers, and extra co-polymers, and "programming" them into a provisional shape at a pre-determined temperature, established by chemical composition.

Ambient heat or heating the material using electrical current helped to induce the shape-morphing effect, which reverts the provisional shape of the component back to its original shape.

Through a direct-ink writing 3D printing method, the LLNL researchers built many structures, including a stent capable of expanding after being exposed to heat.

'4d printing' a box with origami folding

Video Credit: Lawrence Livermore National Laboratory/Youtube.com

"It's like baking a cake," said lead author Jennifer Rodriguez, a postdoc in LLNL's Materials Engineering Division. "You take the part out of the oven before it's done and set the permanent structure of the part by folding or twisting after an initial gelling of the polymer."

Rodriguez stated that scientists can use the materials to develop highly complex components.

If we printed a part out of multiple versions of these formulations, with different transition temperatures, and run it through a heating ramp, they would expand in a segmented fashion and unpack into something much more complex.

Jennifer Rodriguez, LLNL

Using a direct-ink writing 3D printing method, the team generated many types of structures: a collapsed stent capable of expanding after being exposed to heat; a bent conductive device capable of morphing to a straight device when exposed to heat or an electric current; and boxes capable of either opening or closing when heated.

The team believes that this technology would have applications in the medical and aerospace fields, as well as robotic devices and flexible circuits.

We have these materials with 3D structures but they have extra smart properties; they can retain a memory of the previous structure. It opens up a whole new property set. If you can print with these polymer composites you can build things and electrically activate them to unfold. Instead of a dumb lump, you are left with this sentient, responsive material.

James Lewicki, Lab Staff Scientist, LLNL

The study derives from a Laboratory Directed Research & Development project to prepare high-performance 3D-printed carbon fiber composites. LLNL scientists and engineers Cheng Zhu, Eric Duoss, Thomas Wilson and Chris Spadaccini are the other contributors to the paper.