Mar 7 2018

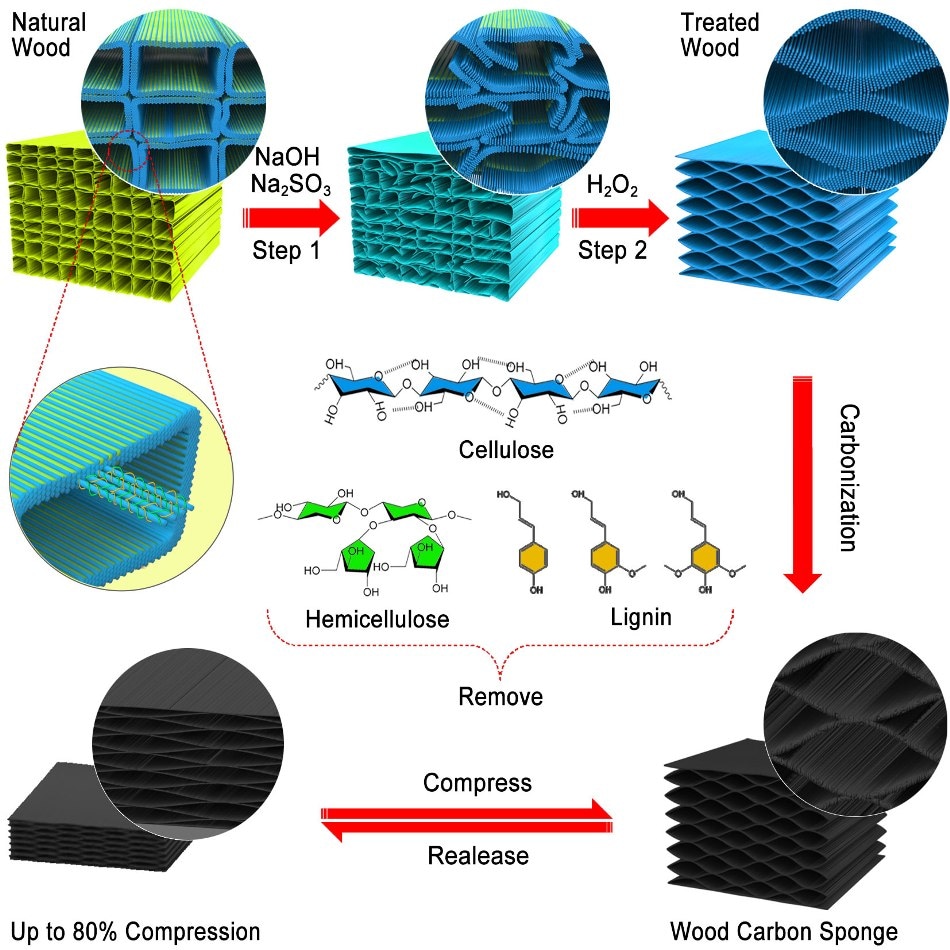

For the first time, engineers from the University of Maryland (UMD) have shown that it is feasible to directly transform wood into a carbon sponge with the potential to withstand repeated compression and other such drastic mechanical conditions. The new sponge can be applied for different applications such as pollutant treatment, energy storage (for example, batteries), and electronic devices and sensors.

Image credit: University of Maryland

Image credit: University of Maryland

The wood carbon sponge developed by the UMD engineers overcomes various restricting factors of other compressible, lightweight carbon sponges as it is less costly, simple, and more sustainable to manufacture.

The majority of the compressible, lightweight carbon sponges are produced from raw materials that are in general nonrenewable fossil resources (for example, graphene) and by adopting a complex fabrication method in which environmentally hazardous chemicals and multiple steps are involved. On the other hand, the UMD scientists adopt a less complicated chemical process to convert balsa wood, a selective biomass-based material that is abundant as well as renewable. The outcomes of the study have been reported in the journal Chem on March 1, 2018.

Our results reveal that rigid and incompressible balsa can be made highly compressible by a chemical treatment and carbonization process, yielding a wood carbon sponge with mechanical compressibility and fatigue resistance and electrical response sensitivity surpassing those of most reported compressible carbonaceous materials.

Liangbing Hu, Author & Associate Professor of Materials Science and Engineering - UMD’s A. James Clark School of Engineering

Hu and his team accomplished the flexible yet strong structure of the wood carbon sponge by using common chemicals to break down the stiff hemicellulose and lignin fibers that preserve the standard cell-wall structure of balsa wood and subsequently heating the treated wood to 1000 °C to transform the organic material into just carbon.

The final impact of the process was to break down the regular, repeated, rectangular pockets that are characteristic to the microstructure of balsa and other woods, and to substitute them with a pile of interlocking, wavy, arch-form carbon sheets, which Hu analogized to be a cross between a honeycomb and a coiled spring.

Usual carbonized wood, synthesized with just the heating step without the need for chemical modifications, is so delicate that any tolerable force applied to it irreversibly crumbles it into dust and ash. In contrast, the wood carbon sponge resisted and recovered from considerable compression for nearly 10,000 successive trials, before being deformed. At first, the researchers were baffled by such a performance.

Our process for creating the wood carbon sponge is unique because we preserve the structure of the wood. This makes the sponge highly compressible and resistant to stress. This means the performance of our wood carbon sponge is one of the best among all lightweight and compressible carbonaceous materials ever reported.

Chaoji Chen, Lead Author & Postdoctoral Researcher - UMD’s A. James Clark School of Engineering

After performing additional electrical and mechanical investigations on the sponge, the team could integrate a piece of it into a strain sensor prototype that is appropriate to be affixed to the finger of a person, a quality advantageous to be applied in health-monitoring or wearable fitness electronics.

The team is confident that the wood carbon sponge can also be integrated into energy storage and conversation technologies (for example, rechargeable batteries and supercapacitors) and water purification devices.

“The abundant applications illustrate the value of a strategy that explores the hidden potentials of natural materials, such as trees, by drawing inspiration from other natural structures and sources,” stated Hu.

The Maryland NanoCenter supported the study.