May 2 2018

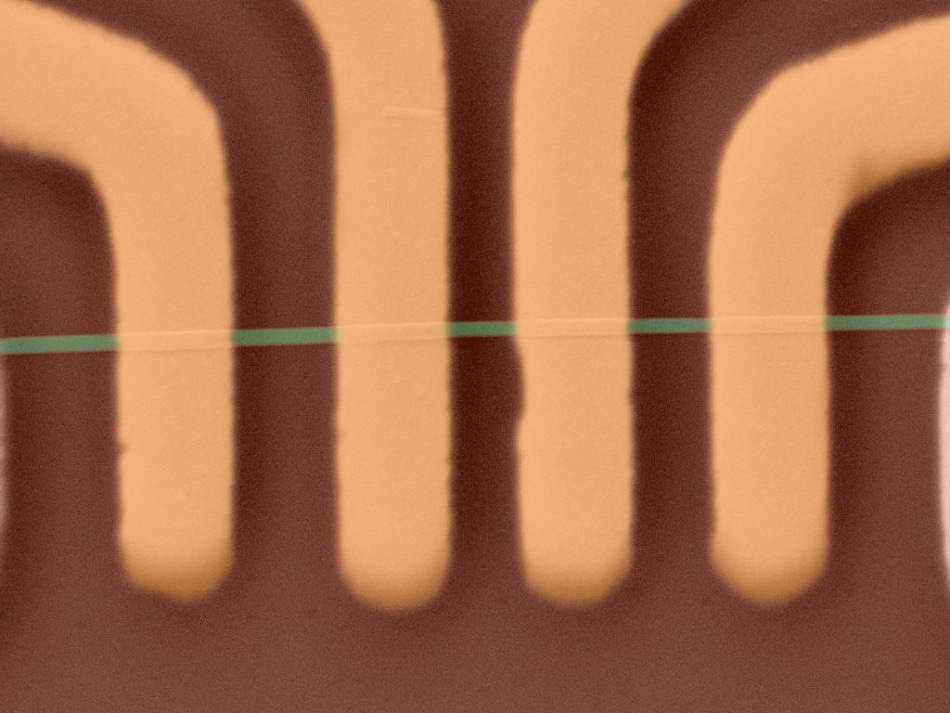

Microscopy image of an electronic device made with 1D ZrTe3 nanoribbons. The nanoribbon channel is indicated in green color. The metal contacts are shown in yellow color. Note that owing to the nanometer-scale thickness, the yellow metal contacts appear to be under the green channel while in reality, they are on top. Pseudo-colors were used for clarity to show the nanoribbon and contacts. (Credit: University of California, Riverside)

Microscopy image of an electronic device made with 1D ZrTe3 nanoribbons. The nanoribbon channel is indicated in green color. The metal contacts are shown in yellow color. Note that owing to the nanometer-scale thickness, the yellow metal contacts appear to be under the green channel while in reality, they are on top. Pseudo-colors were used for clarity to show the nanoribbon and contacts. (Credit: University of California, Riverside)

Prototype devices developed using an exotic material with the ability to conduct a current density 50 times more than traditional copper interconnect technology have been demonstrated by engineers from the University of California, Riverside.

Current density is the measure of electrical current in a specific cross-sectional area at a given point in time. Since the size of transistors in integrated circuits is becoming lesser, they need more and more current densities to function at the needed level. Majority of the traditional electrical conductors (for example, copper) tend to break because of overheating or other factors at high current densities, impeding the development of increasingly small components.

The electronics industry is in the search of substitutes to copper and silicon that can withstand extremely high current densities at sizes of only a few nanometers.

The emergence of graphene led to a massive, global effort toward the analysis of other two-dimensional (2D) layered materials that would satisfy the requirement for nanoscale electronic components that can withstand higher current densities. The 2D materials are formed of a single layer of atoms, but one-dimensional (1D) materials are formed of individual chains of atoms that are weakly linked to each other; however, their potential for electronics has not yet been as widely investigated.

The 2D materials can be considered to be thin slices of bread; in contrast, 1D materials are like spaghetti. When compared to 1D materials, 2D materials appear huge.

A research team headed by Alexander A. Balandin, a distinguished professor of electrical and computer engineering in the Marlan and Rosemary Bourns College of Engineering at UC Riverside, found out that nanoribbons made of zirconium tritelluride, or ZrTe3, have an extremely high current density that largely exceeds that of any traditional metals such as copper.

The innovative approach of the UC Riverside researchers turns the study from 2D to 1D materials—a significant breakthrough for the next generation of electronics.

Conventional metals are polycrystalline. They have grain boundaries and surface roughness, which scatter electrons. Quasi-one-dimensional materials such as ZrTe3 consist of single-crystal atomic chains in one direction. They do not have grain boundaries and often have atomically smooth surfaces after exfoliation. We attributed the exceptionally high current density in ZrTe3 to the single-crystal nature of quasi-1D materials.

Alexander A. Balandin, Professor of Electrical and Computer Engineering, Marlan and Rosemary Bourns College of Engineering, UC Riverside

Essentially, such quasi-1D materials can be directly grown into nanowires with a cross-section that relates to an individual atomic thread, or chain. In this study, the level of current withstood by the ZrTe3 quantum wires was greater than reported earlier for any metals or other 1D materials. It nearly reaches the current density in graphene and carbon nanotubes.

Electronic devices are reliant on special wiring to transfer information between different parts of a system or circuit. When devices are miniaturized by developers, their internal parts must also become smaller in size, and the interconnects transferring information between parts must become the smallest of all. Based on the way they are configured, the ZrTe3 nanoribbons could be designed as either nanoscale device channels or local interconnects for components of the smallest devices.

The experiments by the UC Riverside team were performed with nanoribbons that had been cut from a pre-formed sheet of material. Industrial applications mandate the nanoribbon to be directly grown on the wafer. This manufacturing method is already being developed, and Balandin is hopeful that 1D nanomaterials can be possibly applied in future electronics.

The most exciting thing about the quasi-1D materials is that they can be truly synthesized into the channels or interconnects with the ultimately small cross-section of one atomic thread— approximately one nanometer by one nanometer,.

Alexander A. Balandin, Professor of Electrical and Computer Engineering, Marlan and Rosemary Bourns College of Engineering, UC Riverside

The outcomes of the study will be published this month in IEEE Electron Device Letters.

The first author of the paper, Adane Geremew, is a PhD student in Balandin’s team. Professor Tina Salguero, University of Georgia, produced the bulk materials which were used for exfoliation of nanoribbons.

The Semiconductor Research Corporation and the National Science Foundation supported the study.