Mar 22 2019

Using a new kind of dual polymer material capable of reacting dynamically to its setting, Brown University scientists have created a set of modular hydrogel components that could prove advantageous in a range of soft robotics and biomedical applications.

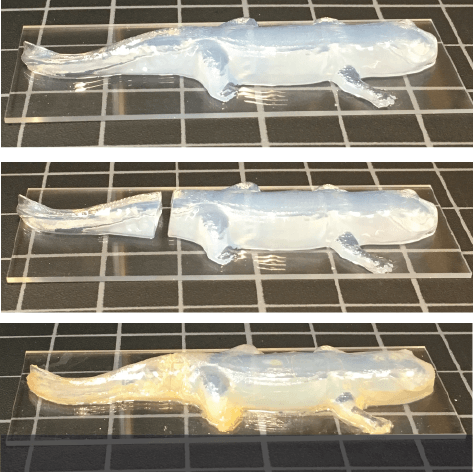

Re-attached - A new kind of hydrogel material developed at Brown has the ability to react dynamically to its environment—bending, twisting and self-adhering on demand. Above, the researchers demonstrated self-adhering behavior on the tail of a 3D printed hydrogel salamander. The self-adhering behavior was also used to make hydrogel building blocks that fit together like LEGO blocks. (Image credit: Wong Lab/Brown University)

Re-attached - A new kind of hydrogel material developed at Brown has the ability to react dynamically to its environment—bending, twisting and self-adhering on demand. Above, the researchers demonstrated self-adhering behavior on the tail of a 3D printed hydrogel salamander. The self-adhering behavior was also used to make hydrogel building blocks that fit together like LEGO blocks. (Image credit: Wong Lab/Brown University)

The components, which are patterned by a 3D printer, can twist, bend, or stick together in response to treatment with specific chemicals. In a paper published in the journal Polymer Chemistry, the scientists showed a soft gripper that can actuate on demand to pick up small objects. They also built LEGO-like hydrogel building blocks that can be judiciously assembled then firmly sealed together to form tailored microfluidic devices—“lab-on-a-chip” systems used for cell cultures, drug screening, and other applications.

The answer to the new material’s functionality is its twin polymer composition, the scientists state.

“Essentially, the one polymer provides structural integrity, while the other enables these dynamic behaviors like bending or self-adhesion,” said Thomas Valentin, a recently graduated Ph.D. student in Brown’s School of Engineering and the paper’s lead author. “So putting the two together makes a material that’s greater than the sum of its parts.”

Hydrogels harden when the polymer strands within them become hitched to one another, a process known as crosslinking. There are two kinds of bonds that bind crosslinked polymers together: ionic and covalent. Covalent bonds are quite robust, but irreversible. Once two strands are connected covalently, it would be easier to break the strand than break the bond. Ionic bonds, conversely, are not quite as robust, but they can be reversed. Integrating ions (molecules or atoms with a net positive or negative charge) will cause the bonds to develop. Removing ions will make the bonds to split.

To create this new material, the scientists integrated one polymer that is covalently crosslinked, known as PEGDA, and one that is ionically crosslinked, known as PAA. The PEGDA’s robust covalent bonds keep the material together, while the PAA’s ionic bonds make it receptive. Placing the material in an ion-rich environment makes the PAA to crosslink, meaning it becomes stiffer and contracts. Remove those ions away, and the material turns soft and swells as the ionic bonds break. The same process also allows the material to be self-adhesive when preferred. Place two individual pieces together, incorporate some ions, and the pieces attach securely together.

That combination of dynamic behavior and strength allowed the scientists to create their soft gripper. They patterned each of the gripper’s “fingers” to contain pure PEGDA on one side and a PEGDA-PAA mixture on the other. Incorporating ions caused the PEGDA-PAA side to shrink and toughen, which pulled the two gripper fingers together. The scientists demonstrated that the arrangement was adequately strong to lift small objects weighing around a gram, and hold them against gravity.

There’s a lot of interest in materials that can change their shapes and automatically adapt to different environments. So here we demonstrate a material the can flex and reconfigure itself in response to an external stimulus.

Ian Y. Wong, Paper’s Corresponding Author and Assistant Professor of Engineering, Brown University.

But potentially a more direct application is in microfluidics, the scientists state.

Hydrogels are an appealing material for microfluidic devices, particularly those utilized in biomedical testing. They are flexible and soft like human tissue, and generally safe. The issue is that hydrogels are frequently tough to pattern with the complex chambers and channels required in microfluidics.

But this new material—and the LEGO block concept it facilitates—provides a possible solution. The 3D printing process allows multifaceted microfluidic architectures to be added into each block. Those blocks can then be assembled using a socket configuration quite similar to that of real LEGO blocks. Incorporating ions to the assembled blocks renders a water-tight seal.

The modular LEGO blocks are interesting in that we could create a prefabricated toolbox for microfluidic devices. You keep a variety of preset parts with different microfluidic architectures on hand, and then you just grab the ones you need to make your custom microfluidic circuit. Then you heal them together and it’s ready to go.

Thomas Valentin, Ph.D. Paper’s Lead Author, School of Engineering, Brown University.

Moreover, storing the blocks for long periods prior to use does not seem to be an issue, the scientists say.

“Some of the samples we tested for this study were three or four months old,” said Eric DuBois, a Brown undergraduate and the paper’s co-author. “So we think these could remain usable for an extended period.”

The scientists say they will pursue improving the material, potentially refining the properties of the polymers to obtain even more functionality and durability.

The paper’s other authors were Catherine Machnicki, Dhananjay Bhaskar and Francis Cui. The work was supported by the U.S. Department of Education through a GAANN Training Grant in the Applications and Implications of Nanotechnology (P200A150037), and Brown University through a Karen T. Romer Undergraduate Research and Teaching Award (UTRA).