May 15 2019

Of late, multi-component materials have become one of the most prospective materials in biomedical and engineering applications. In contrast to traditional alloys, the composition design of multi-component materials is more complicated, and numerous alloys with various compositions need to be prepared and analyzed.

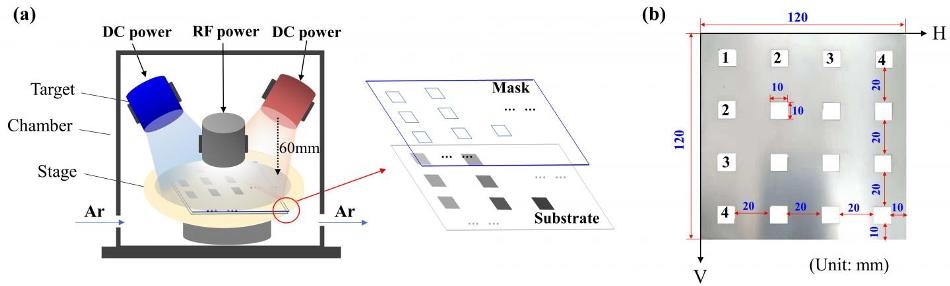

(a) Schematic diagram of high-throughput, (b) physical shadow mask. (Image credit: ©Science China Press)

(a) Schematic diagram of high-throughput, (b) physical shadow mask. (Image credit: ©Science China Press)

Furthermore, the link between the mixing entropy and performance of multi-component materials are nonlinear, thus the performance and structure cannot be successfully predicted by mixing entropy values, which makes it harder to design the alloys efficiently. In this scenario, high-throughput technology is an effective approach to solve this matter. A new study stated that high-throughput screening of the composition and Young's modulus of Ti-Zr-Nb alloy was positively accomplished by co-sputtering technology with the help of a physical mask.

The research paper titled "High-throughput screening for biomedical applications in a Ti-Zr-Nb alloy system through masking co-sputtering", has been published in SCIENCE CHINA Physics, Mechanics & Astronomy in Issue 9 of 2019, with Prof. Yong Zhang from Beijing University of Science and Technology as the corresponding author.

To produce the new alloys with special properties, for instance, superior mechanical properties, or biomedical properties, is typically a time-consuming process. The conventional "trial and error" technique cannot match the requirements. On the other hand, because of the limitations of research techniques, just some specific compositions can be achieved from a set of experiments using conventional approaches.

Taking biomedical materials as an illustration, the acquired low Young's modulus value is usually a relatively low value in a small composition region, instead of the lowest value of a global system. Thus, the conventional "trial and error" technique unavoidably causes incompleteness and contingency in research outcomes.

High-throughput technology is an operative way to get a composition with appropriate properties in a larger composition region while enhancing efficiency. On the foundation of multi-target co-sputtering, an auxiliary physical mask was used to enable the preparation of compositional gradient materials and 16 independent specimens were achieved in this research.

In particular, Young's modulus of the Ti-Zr-Nb alloys was tested by nanoindentation. The tested Young's modulus values were plotted to 3D surface maps and contour maps. Importantly, a low Young's modulus region is apparent. To establish whether a lower modulus composition occurred in the blank areas between the specimens with lower Young's moduli, additional optimization of the composition was carried out. According to the screening results, the formation, structure, and mechanical properties of bulk alloys can be discussed more thoroughly.

It should be kept in mind that the application of the physical mask is required to stop component diffusion between the sample units. On the whole, the composition of the materials gotten by the multi-target co-sputtering could be constantly altered, which means that the process of component diffusion is unavoidable. To guarantee the composition difference of the specimens, an independent mask has been used in this research.

This research not only offers new multi-component alloys with noticeable properties for real-world applications, but also provides new insight on the development of high-throughput preparation technology on the whole.