Aug 6 2019

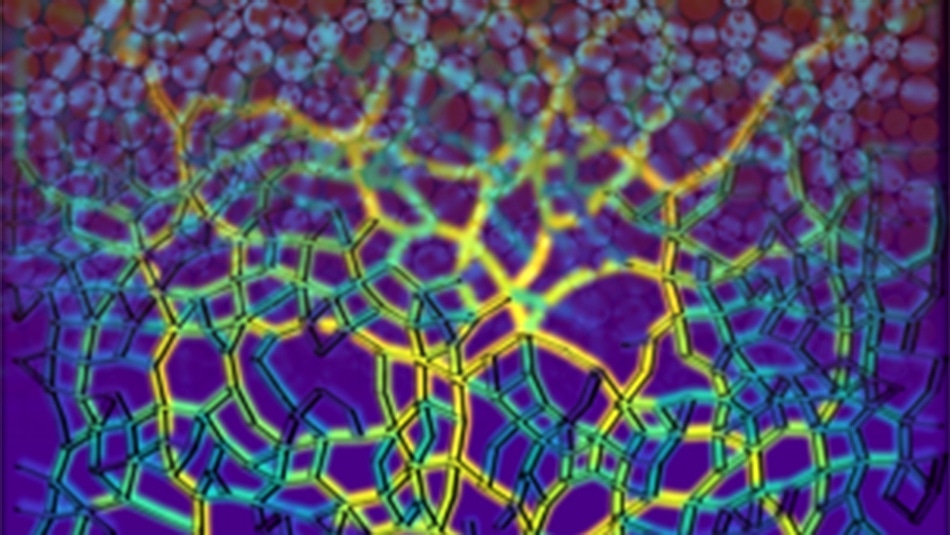

Disordered materials—like fiber, cellular foams, and polymer networks—are widely used in applications ranging from architecture to biomedical scaffolding.

(Image credit: North Carolina State University)

(Image credit: North Carolina State University)

Forecasting when and where these materials may fail could influence the materials used at present as well as future designs. Scientists from North Carolina State University and the University of California Los Angeles could predict likely points of failure in 2D disordered laser-cut lattices, eliminating the need to study comprehensive states of the material.

A network of connections between slender beams that intersect at different points—or nodes—throughout the material makes up the interior of disordered materials. Their structure enables compression as well as deformation, allowing them to endure different kinds of force.

Estelle Berthier, a postdoctoral researcher at NC State and lead author of a paper reporting the research, set out to find out if it is possible to forecast where failure is most liable to take place in a disordered network.

Berthier and co-author Karen Daniels, professor of physics at NC State, created lattices based on the contact networks noticed within granular materials and examined a property called geodesic edge betweenness centrality (GEBC).

The importance of an edge in a network is in terms of its ability to connect different parts of the network using the shortest path. In our model lattice, when you connect each node of the network taking the shortest path, you use one of these beams or edges.

Estelle Berthier, Postdoctoral Researcher, North Carolina State University

Berthier continued, “If you go through a particular edge a lot, then that edge has high centrality. Think about using the shortest path, or road, between two cities. The centrality value is the most popular road on that shortest path.”

Together with UCLA mathematician Mason Porter, the scientists used a computer algorithm to compute the GEBC for the lattice and identified that edges with a higher centrality value than the mean were the most likely to fail.

“If you have higher traffic on a particular road, then there’s more wear and tear,” Berthier states. “Similarly, a higher centrality value means that a particular path within the material is dealing with more force ‘traffic’, and should be monitored more closely or perhaps shored up in some way.”

The scientists determined that the GEBC values alone were adequate to detect failure sites in the material.

“One of the things that surprised me about the results was that the calculations don’t require us to know any of the materials’ properties, just how the parts have been connected together,” stated Daniels. “Of course, we can make the predictions even stronger by including information about the physical interactions in our calculations.”