By Toby CharnockOct 18 2019

By Toby CharnockOct 18 2019Researchers from Northwestern University have designed an extremely fast and large futuristic 3D printer that can print an object the size of an adult human within a few hours.

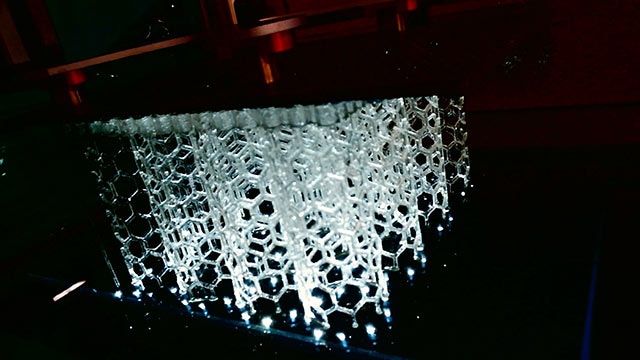

HARP prints vertically, using projected UV light to cure liquid resins into hardened plastic. (Image credit: Northwestern University)

HARP prints vertically, using projected UV light to cure liquid resins into hardened plastic. (Image credit: Northwestern University)

The new printer is called “HARP” (high-area rapid printing) and enables a record-breaking throughput that can produce products on demand. During the last three decades, most efforts in 3D printing have been directed towards pushing the boundaries of legacy technologies.

Frequently, the quest for larger parts has come at the cost of throughput, speed, and resolution. With HARP technology, this compromise is needless, facilitating it to contend with both the throughput and resolution of conventional manufacturing methods.

The prototype HARP technology measures 13 ft in height with a 2.5 ft2 print bed. It is capable of printing about half a yard in an hour—a record throughput for the 3D printing field. This means it can print single, large parts or several different small parts simultaneously.

3D printing is conceptually powerful but has been limited practically. If we could print fast without limitations on materials and size, we could revolutionize manufacturing. HARP is poised to do that.

Chad A. Mirkin, George B. Rathmann Professor of Chemistry and Lead Product Developer, Northwestern University

Mirkin expects that HARP will hit the market in the next 18 months.

Details of the research were published on October 18th in the journal Science. Mirkin is the George B. Rathmann Professor of Chemistry in Northwestern’s Weinberg College of Arts and Sciences and director of the International Institute of Nanotechnology. David Walker and James Hedrick, both researchers in Mirkin’s laboratory, co-authored the paper.

Keeping it cool

The new technology uses a new, patent-pending version of stereolithography, a type of 3D printing that changes liquid plastic into solid objects. HARP prints vertically and uses projected UV light to cure the liquid resins into hardened plastic. This process can print pieces that are elastic, hard, or even ceramic. These continually printed parts are mechanically strong in contrast to the laminated structures typical of other 3D-printing technologies. They can be used as parts for fashion, cars, dentistry, airplanes, orthotics, and a lot more.

A huge restrictive factor for existing 3D printers is heat. All resin-based 3D printers produce plenty of heat while working at fast speeds—at times beyond 180 °C. Not only does this give rise to hazardously hot surface temperatures, it can also result in printed parts cracking and deforming. The faster it is, the more heat the printer produces. Furthermore, if it is big and swift, the heat is extremely intense.

This issue has influenced many 3D printing companies to keep it small. “When these printers run at high speeds, a great deal of heat is generated from the polymerization of the resin,” Walker said. “They have no way to dissipate it.”

“Liquid Teflon”

HARP avoids this problem with a non-stick liquid that acts like liquid Teflon. The Northwestern technology projects light via a window to harden resin on top of a vertically moving plate. The liquid Teflon flows over the window to eliminate heat and then circulates it via a cooling unit.

“Our technology generates heat just like the others,” Mirkin said. “But we have an interface that removes the heat.”

“The interface is also nonstick, which keeps the resin from adhering to the printer itself,” Hedrick added. “This increases the printer’s speed by a hundredfold because the parts do not have to be repeatedly cleaved from the bottom of the print-vat.”

Goodbye, warehouses

Existing manufacturing techniques can be tedious processes. They frequently necessitate filling pre-designed molds, which are costly, static, and take up vital storage space. Using molds, producers print parts beforehand—regularly guessing how many they could need—and store them in large warehouses.

Although 3D printing is shifting from prototyping to manufacturing, existing 3D printers’ speed and size have restricted them to small-batch production. HARP is the first printer that can manage large batches and large parts besides small parts.

When you can print fast and large, it can really change the way we think about manufacturing. With HARP, you can build anything you want without molds and without a warehouse full of parts. You can print anything you can imagine on-demand.

Chad A. Mirkin, George B. Rathmann Professor of Chemistry and Lead Product Developer, Northwestern University

Largest in its class

While other print technologies have decelerated or minimized their resolution to go big, HARP does not make such discounts.

Obviously there are many types of 3D printers out there—you see printers making buildings, bridges and car bodies, and conversely you see printers that can make small parts at very high resolutions. We’re excited because this is the largest and highest throughput printer in its class.

David Walker, Entrepreneur-In-Residence, Study Co-Author, Northwestern University

Printers on the scale of HARP frequently produce parts that have to be machined or sanded down to their final geometry, causing the labor cost in the production process to increase considerably. HARP is in a category of 3D printers that employ high-resolution light-patterning to attain ready-to-use parts without wide-ranging post-processing. The outcome is a commercially feasible route to the production of consumer goods.

Nano goes big

Mirkin, a world-famous expert in nanotechnology, invented the world’s smallest printer in 1999. It was called dip-pen nanolithography, and the technology used a miniature pen to pattern nanoscale features. He then advanced this to an array of miniature pens that channels light via each pen to locally produce features from photo-sensitive materials. HARP’s special non-stick interface came to be while working to create this technology into a nanoscale 3D printer.

“From a volumetric standpoint, we have spanned over 18 orders of magnitude,” Mirkin said.