Sep 30 2020

A group of researchers from Far Eastern Federal University (FEFU) along with their collaborators from Turkey, Austria, Slovakia, Russia (MISIS, MSU), and the United Kingdom has identified a new method to hydrogenate thin metallic glass layers at room temperatures.

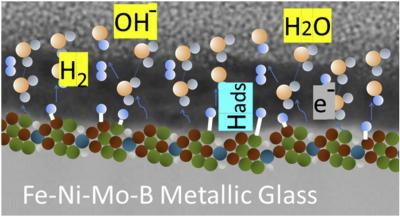

Fe-Ni-Mo-B Metallic Glass, graphical abstract. Image Credit: FEFU press office.

Fe-Ni-Mo-B Metallic Glass, graphical abstract. Image Credit: FEFU press office.

The new technology can significantly expand the scope of low-cost, high-performance, and energy-efficient materials and techniques that can be employed in the area of hydrogen energy. An article about the latest study was recently published in the Journal of Power Sources.

The researchers created an amorphous nanostructure (FeNi-based metallic glass) that can be utilized in the field of hydrogen energy to accrue and store hydrogen, specifically, as a substitute for Li-ion batteries used in compact systems.

Metallic glass could possibly replace palladium, which is a costly element being used in hydrogen systems today. The main hindrance is the dearth of economically feasible energy storage systems and this problem prevents the scale-up of hydrogen energy to the industrial level. But now with the latest development, the researchers are one step closer to solving this issue.

Hydrogen is the most common chemical element in the Universe, a source of clean renewable energy that has the potential to replace all types of fuel used today. However, its storage poses a major technological problem. One of the key materials used to store and catalyze hydrogen is palladium. However, it is very expensive and has a low affinity to oxidizing or reducing environments under extreme conditions.

Yurii Ivanov, Assistant Professor, Department of Computer Systems, School of Natural Sciences, Far Eastern Federal University

Ivanov continued, “These factors prevent hydrogen energy from being used on the industrial level. The problem can be solved with metallic glasses. They are amorphous metals and lack long-range atomic order.”

Compared to crystalline palladium, metallic glasses are much cheaper and more resistant to aggressive environments. Moreover, due to the so-called atomic free volume (i.e. space between atoms), such glasses can 'soak up' hydrogen more effectively than any other materials with crystalline structure.

Yurii Ivanov, Assistant Professor, Department of Computer Systems, School of Natural Sciences, Far Eastern Federal University

Ivanov believes that metallic glass has significant potential in the energy sector because of its amorphous structure, absence of specific defects that are usual for polycrystalline metals (like grain boundaries), and excellent resistance to corrosion and oxidation.

This is a unique work because electrochemical techniques are not only used to hydrogenate metallic glasses but also applied to analyze their potential to absorb hydrogen.

Typical hydrogenation techniques (like gas adsorption) need high pressure and temperature which have a negative impact on the characteristics of metallic glasses and narrows the scope of materials that can be utilized in the research work.

Electrochemical hydrogenation is different from gas adsorption and causes hydrogen to react with the surface of an electrode (produced from FeNi metallic glass) at room temperatures, just like the way it is done for palladium.

The latest technique can work as an alternative to the standard gas-solid reaction for alloys that have low capacity or low speed of hydrogen emission and absorption.

The researchers have also proposed a novel concept of “'effective volume” that can be utilized to investigate the efficiency of the absorption and emission of hydrogen by metallic glasses. To do so, the composition and thickness of the glass-hydrogen reaction area are quantified using X-ray photoelectron spectroscopy and high-resolution electron microscopy.

In the days to come, the researchers are planning to create and improve the compositions of new metallic glass for viable energy applications.

Previously, a group of material scientists from FEFU, Cambridge (United Kingdome), and the Chinese Academy of Sciences, had designed a technique of “rejuvenation” of 3D metallic glasses that have shown to be highly promising for practical applications. The scientists have made these metallic glasses more moldable and resistant to above-critical loads.

These enhanced metallic glasses can be employed in a variety of fields, ranging from numerous sensors and transformer cores to plastic electronics, protective coatings of satellites, and medical implants.

Journal Reference:

Sarac, B., et al. (2020) Surface-governed electrochemical hydrogenation in FeNi-based metallic glass. Journal of Power Sources. doi.org/10.1016/j.jpowsour.2020.228700.