Scientists from the College of Science and Engineering of the University of Minnesota Twin Cities have created an easier, affordable, and safest technology that will enable a “stubborn” group of metals and metal oxides to be made into thin films utilized in several computer components, electronics, and other applications.

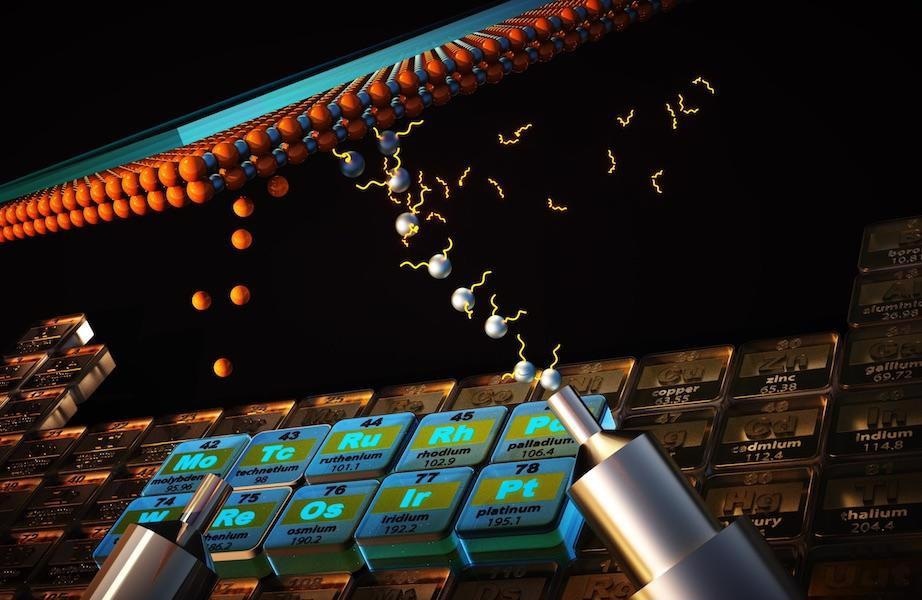

By adding combinations of carbon, hydrogen, and oxygen atoms to stubborn, hard-to-evaporate metals like tungsten and platinum, University of Minnesota Twin Cities researchers were able to transform the elements into thin films more cheaply and safely. Image Credit: Bharat Jalan MBE Lab, University of Minnesota.

By adding combinations of carbon, hydrogen, and oxygen atoms to stubborn, hard-to-evaporate metals like tungsten and platinum, University of Minnesota Twin Cities researchers were able to transform the elements into thin films more cheaply and safely. Image Credit: Bharat Jalan MBE Lab, University of Minnesota.

The study has been reported in Proceedings of the National Academy of Sciences of the United States of America (PNAS), a peer-reviewed, multidisciplinary, high-impact scientific journal.

The scientists collaborated with the University of Minnesota’s Technology Commercialization Office to patent the technology and have already gained attention from the industry.

Various metals and their compounds should be made into thin films before being utilized in technological products such as displays, electronics, fuel cells, or catalytic applications. But “Stubborn” metals, which contain elements like tungsten, ruthenium, iridium, and platinum, among others, are very hard to be converted into thin films as they need extremely high temperatures (generally more than 2,000 °C) to evaporate.

Essentially, researchers produce these metal films by making use of methods like sputtering and electron beam evaporation. The latter involves melting and evaporating metals at high temperatures and enabling a film to form on top of wafers. However, this traditional method is very costly, involves a lot of energy, and might also be unsafe due to the high voltage utilized.

At present, scientists from the University of Minnesota have come up with a new method to evaporate these metals at considerably lower temperatures, of less than 200 °C rather than several thousand.

The researchers developed and added organic ligands—mixtures of hydrogen, carbon, and oxygen atoms—to the metals to considerably raise the materials’ vapor pressures, thereby making them simpler to evaporate at lower temperatures. Apart from being simpler, the new method also makes higher quality materials that can be scaled easily.

The ability to make new materials with ease and control is essential to transition into a new era of energy economy. There is already a historical link between the innovation in synthesis science and the development of new technology. Millions of dollars go into making materials for various applications. Now, we’ve come up with a simpler and cheaper technology that enables better materials with atomic precision.

Bharat Jalan, Study Senior Author, Associate Professor, and Shell Chair, Department of Chemical Engineering and Materials Science, University of Minnesota

Jalan is also an expert in Material Synthesis.

Such metals are utilized to make myriad products, right from semiconductors for computer applications to display technology. For instance, platinum also makes a fine catalyst for the conversion of energy and storage and is being considered for use in spintronic devices.

Bringing down the cost and complexity of metal deposition while also allowing for deposition of more complex materials like oxides will play a large role in both industrial and research efforts. Now that depositing these metals like platinum will become easier, we hope to see renewed interest in the more complex materials which contain these stubborn metals.

William Nunn, Study First Author and Chemical Engineering and Materials Science Graduate Student, University of Minnesota

Nunn is also a recipient of the department’s Robert V. Mattern Fellowship.

Besides Jalan and Nunn, the research team involved University of Minnesota Department of Chemical Engineering and Materials Science graduate students Anusha Kamath Manjeshwar, Jin Yue, Tristan K. Truttmann, and postdoctoral researcher Anil Rajapitamahuni.

The study was financially supported primarily by the U.S. Department of Energy, with further support from the Air Force Office of Scientific Research and the National Science Foundation.

Journal Reference:

Nunn, W., et al. (2021) Novel synthesis approach for “stubborn” metals and metal oxides. Proceedings of the National Academy of Sciences of the United States of America. doi.org/10.1073/pnas.2105713118.