Hydrogen is a chemical element that has been extensively recommended as an alternative fuel with zero carbon emission. However, most of the commercial hydrogen fuel production is achieved from the refining of fossils fuels.

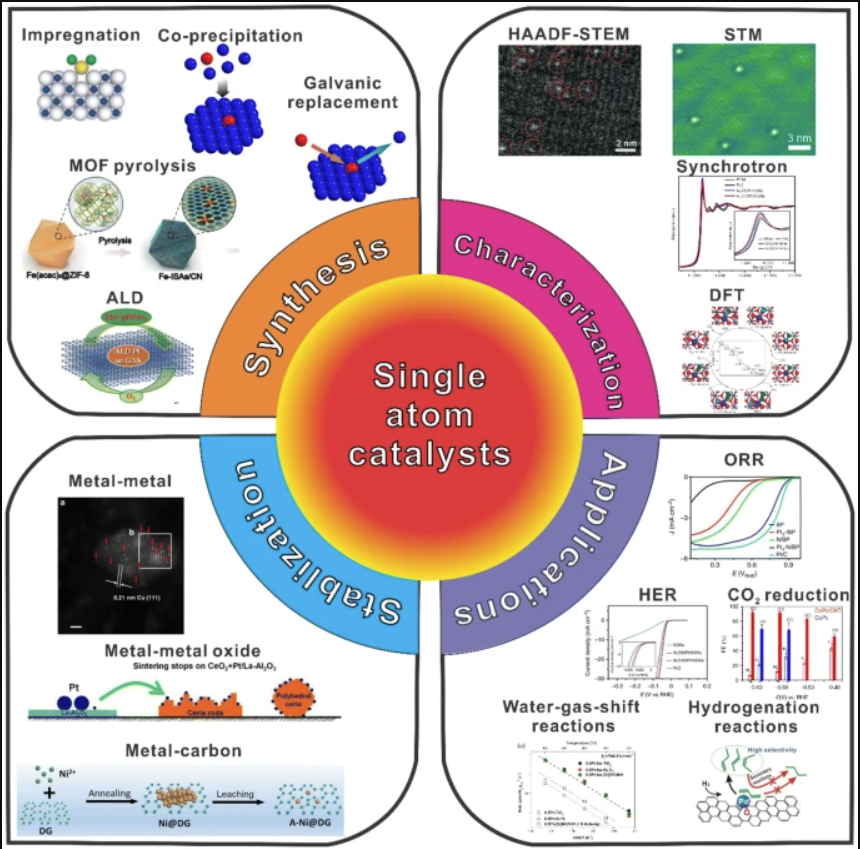

Image Credit: Cheng, N., Et al., (2019) Single-Atom Catalysts: From Design to Application. [Online] Electrochemical Energy Reviews, 2(4), pp.539-573. Available at: https://doi.org/10.1007/s41918-019-00050-6

Image Credit: Cheng, N., Et al., (2019) Single-Atom Catalysts: From Design to Application. [Online] Electrochemical Energy Reviews, 2(4), pp.539-573. Available at: https://doi.org/10.1007/s41918-019-00050-6

Researchers have been motivated to develop alternative technologies due to the limited reservoir of fossils fuels and their negative impact on the surroundings. This technology would help produce hydrogen fuel via an environmentally friendly process.

Electrolysis of water, which is ample in nature, is one method by which the so-called “green hydrogen” can be produced by using electricity acquired from a renewable energy source. But the efficiency of water electrolysis is considerably limited as a result of the slow oxygen evolution reaction (OER), which needs a high thermodynamic voltage of 1.23 V.

To store energy for hydrogen generation, substituting sluggish water electrolysis with urea oxidation reaction (UOR) provides a great promise, as a result of the thermodynamically favorable (0.37 V, thermodynamic voltage) conditions of urea electrolysis. There is an extra benefit of reducing the problem of urea contamination, where nearly 2,200 billion tons of urea-rich wastewater is being discharged into the river annually.

Catalysts based on noble metals, like rhodium (Rh) and platinum (Pt), are utilized to improve the rate of the oxidation process. But such noble metal catalysts are very costly and display poor performance under long-lasting operation.

In recent times, single-atom catalysts (SACs) have exhibited remarkable performances than nanomaterials-based counterparts. But the low metal loading (<3 wt%) of SACs, which is due to the tendency of the surface atoms to migrate, renders a major problem for a scalable application.

Under the guidance of Associate Director Hyoyoung Lee of the Center for Integrated Nanostructure Physics within the Institute for Basic Science (IBS) situated at Sungkyunkwan University, the research group from IBS came up with a strategy to reach ultra-high loading of single metal atom sites. This was achieved by initiating surface strain on the support material, enabling remarkable urea oxidation aided hydrogen fuel generation.

We used liquid nitrogen quenching method to generate tensile strain on the surface of cobalt oxide (Co3O4). The ultra-high cooling rate expands the lattice parameter of the quenched sample because of thermal expansion, giving rise to tensile strain on the oxide surface.

Ashwani Kumar, Study First Author and PhD Candidate, Center for Integrated Nanostructure Physics, Institute for Basic Science

“The strained surface of Co3O4 stabilized ~200% higher loading of rhodium single atom (RhSA; 6.6 wt% bulk loading and 11.6 wt% surface loading) sites compared to the pristine Co3O4 surface. We found that the strained surface can significantly increase the migration energy barrier of RhSA compared to the pristine surface, inhibiting their migration and agglomeration,” added Kumar.

We were very excited to discover that the high loading of RhSA stabilized on the strained Co3O4 surface demonstrated exceptional UOR activity and stability in both alkaline and acidic media, which was much superior to the commercial Pt/C and Rh/C. This surface strain strategy in the field of SACs has never been reported until our findings.

Hyoyoung Lee, Study Corresponding Author and Associate Director, Center for Integrated Nanostructure Physics, Institute for Basic Science

Furthermore, the scientists discovered that this plan for the high-loading of single-atom sites was not only restricted to rhodium. Ultra-high loading of other noble metals like iridium, platinum and ruthenium-based single-atom sites was stabilized with the help of the strained surface strategy. This offers a base for a more general application of this breakthrough.

The catalytic efficiency and the working voltage required for urea oxidation were assessed by the research group by making use of this new catalyst. The latest catalyst (RhSAo n strained Co3O4) needed only 1.28 V versus reversible hydrogen electrode (RHE) to achieve a current density of 10 mA (milliampere) per cm2 of the electrode, which was lower compared to that of the commercial Rh and Pt catalysts’ needs of 1.34 and 1.45 V, respectively.

Besides, the catalyst also exhibited long-term stability for 100 hours without any structural change. The group utilized density functional theory simulation to investigate the origin of the new catalyst’s exceptional performance. It was disclosed to be a result of the excellent urea adsorption and stabilization of CO/NH intermediates. Additionally, the electrolysis of urea saved approximately 16.1% more energy than water electrolysis for hydrogen generation.

This study provides a general strategy for stabilizing high-loading of single-atom sites for scalable applications, which was a long-standing problem in the filed of SACs. In addition, this study takes us a step closer to a carbon-free and energy-saving hydrogen economy.

Hyoyoung Lee, Study Corresponding Author and Associate Director, Center for Integrated Nanostructure Physics, Institute for Basic Science

“This highly efficient urea oxidation electro-catalyst will help us overcome long-term challenges of the fossil fuel refining process: to produce high-purity hydrogen for commercial applications at a low price and in an eco-friendly manner,” added Lee.

Journal Reference:

Kumar, A., et al. (2021) Discovering Ultrahigh-Loading of Single-Metal-Atom via Surface Tensile-Strain for Unprecedented Urea Electrolysis. Energy & Environmental Science. doi.org/10.1039/D1EE02603H.